Pipeline cleaning equipment

A technology for cleaning equipment and pipelines, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to clean, poor cleaning effect, oil pipeline damage, etc., and achieve the effect of improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

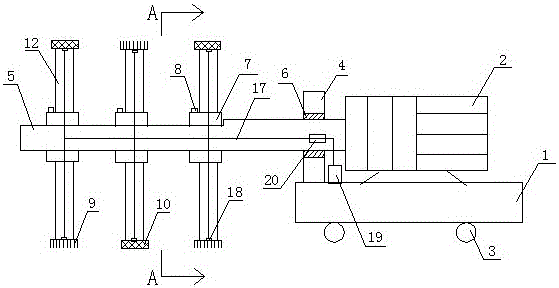

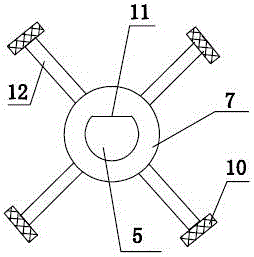

[0020] Such as figure 1 , figure 2 As shown, a pipeline cleaning equipment includes a base 1, a motor 2, a column 4, a rotating shaft 5 and a cleaning device. The column 4 and the motor 2 are arranged on the base 1, and a circular hole is arranged on the column, and a circular hole is arranged in the circular hole. There is a bearing 6, and the cleaning device is installed on the rotating shaft 5, and the rotating shaft 5 is connected to the output shaft of the motor 2 through (or passing through) the bearing 6. The cleaning device of the present invention includes a connecting plate 7 and a connecting rod 12. The connecting disc 7 is sleeved on the rotating shaft 5 and fixed with the rotating shaft 5. There are at least two connecting discs 7, which are evenly sleeved on the rotating shaft 5. The connecting rod 12 is radially connected with the outer circumference of the connecting disc ( Such as figure 2 shown), and evenly distributed along the outer circumference of the...

Embodiment 2

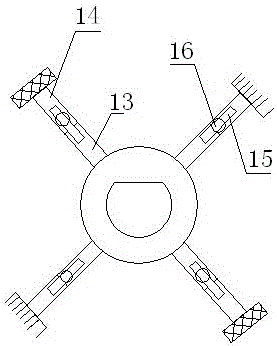

[0025] Such as figure 1 with image 3 As shown, a pipeline cleaning equipment includes a base 1, a motor 2, a column 4, a rotating shaft 5 and a cleaning device. The column 4 and the motor 2 are arranged on the base 1, and a circular hole is arranged on the column, and a circular hole is arranged in the circular hole. There is a bearing 6, and the cleaning device is installed on the rotating shaft 5, and the rotating shaft 5 is connected to the output shaft of the motor 2 through (or passing through) the bearing 6. The cleaning device of the present invention includes a connecting plate 7 and a connecting rod 12. The connecting disc 7 is sleeved on the rotating shaft 5 and fixed with the rotating shaft 5. There are at least two connecting discs 7, which are uniformly sleeved on the rotating shaft 5. The connecting rod 12 includes a fixed plate 13 and a guide rod 14, which are fixed The plate 13 is plate-shaped, and the fixed plate 13 is radially connected with the outer circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com