Automatic assembly production line of spool

An automatic assembly and production line technology, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as low production efficiency, low processing accuracy, and large space occupied by assembly lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

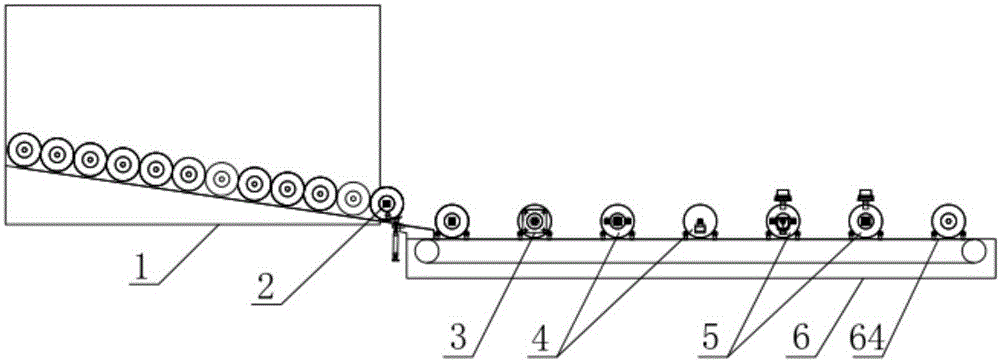

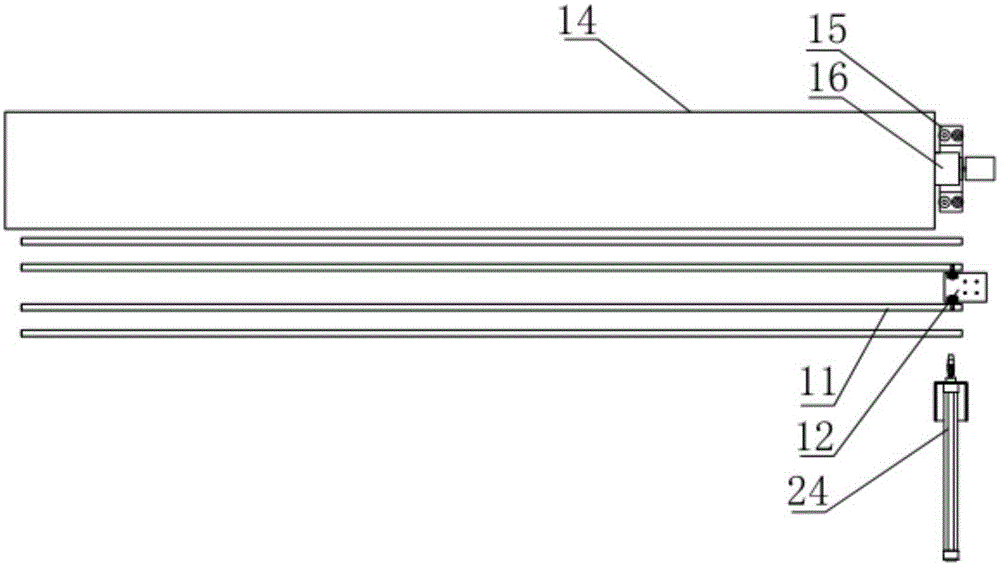

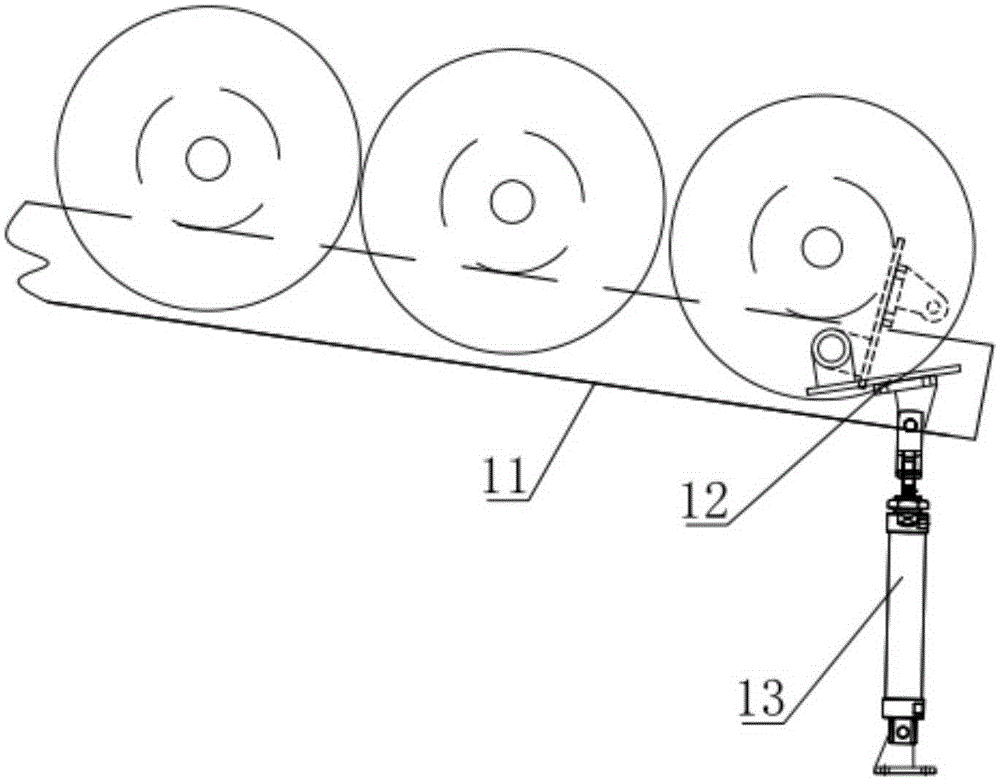

[0034] Such as figure 1 with 7 As shown, the automatic assembly production line of the I-shaped wheel in this embodiment is used for automatic assembly of the I-shaped wheel, that is, inserting the core tube into the wheel blank, and then performing processing such as edge expansion, press-fitting, spot welding, etc., and finally forming a complete I-shaped wheel . The I-wheel automatic assembly production line includes a feeding mechanism 1, an insertion mechanism 2, a detection device, an edge expansion and pressing device 3, an automatic spot welding device 4, a correction device 5 and a chain conveyor 6. The feeding mechanism 1 connects the core tube and the wheel The blank is delivered to the inserting mechanism 2, which inserts the core tube into the wheel blank, and the inserted wheel blank falls on the chain plate conveyor 6, and the chain plate conveyor 6 sequentially inserts the inserted wheel blank Send to the station of the detection device, the station of the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com