Fiber cut-off device

A cutting device and fiber technology, applied in the direction of textiles and papermaking, metal processing, textile material cutting, etc., can solve the problems of limited contact area, time-consuming and labor-intensive cutting process, etc., and achieve the effect of increasing the contact area and approaching the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

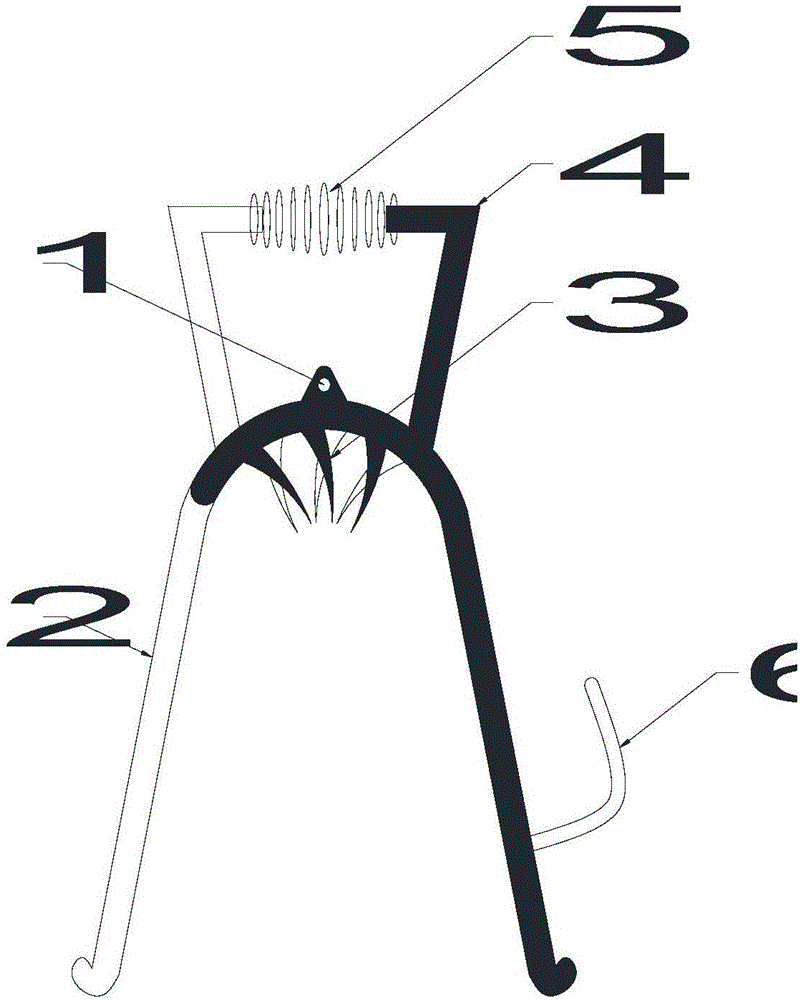

[0024] Embodiment one, see figure 1 , a fiber cutting device, comprising two shear bodies and a connector 1, characterized in that: the shear body includes a shear handle 2 and a shear joint part, the shear joint part is arc-shaped, and the inside of the shear joint part is provided with A plurality of scissors 3, the scissors 3 are provided with a cutting edge, the outer side of the scissor part is provided with a shaft hole, and the scissor handle 2 is arranged on the inner side of the scissors. When in use, the scissors 3 are inserted into the fiber tuft, and then the scissor handle 2 is pressed together to cut off the fiber tuft.

[0025] As a further improvement of the above solution, a support rod 4 is provided on the outside of the scissors, and a spring 5 is provided between the support rods 4 . The scissor handle 2 can be automatically restored to the state of preparation before cutting, which increases ease of use and saves operating time.

[0026] As a further imp...

Embodiment 2

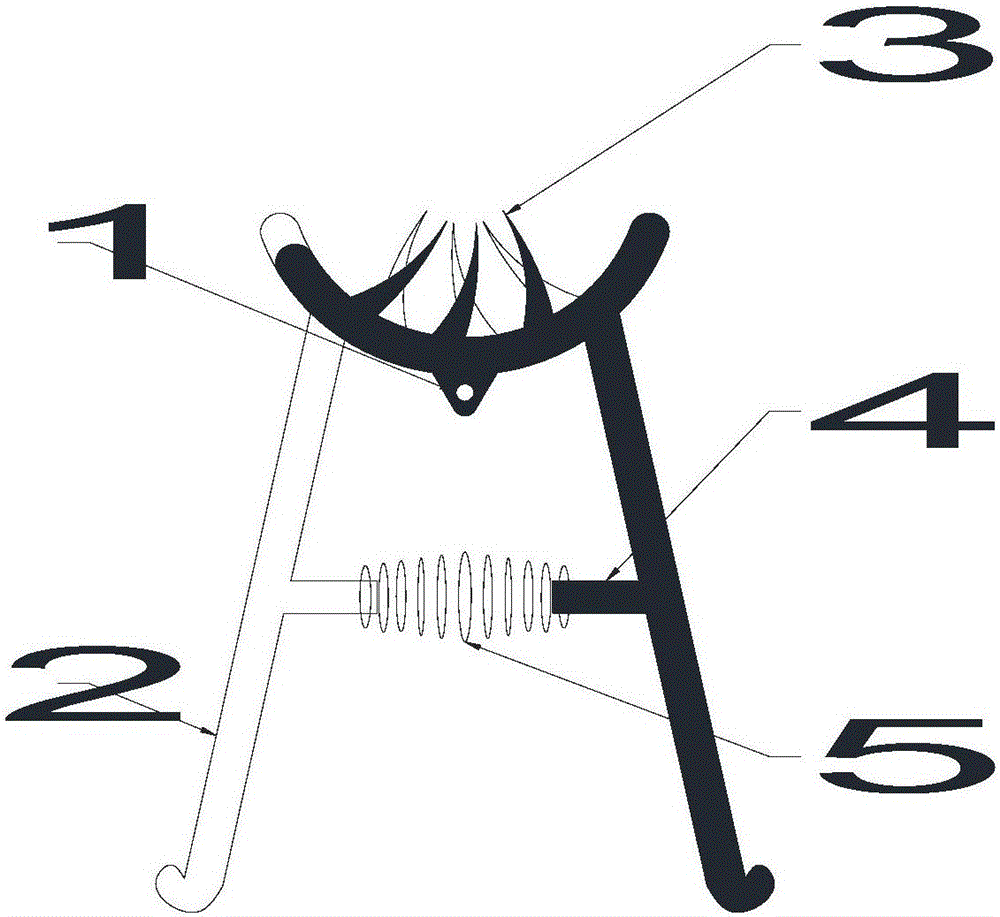

[0031] Embodiment two, see figure 2 , a fiber cutting device, comprising two shear bodies and a connector 1, characterized in that: the shear body includes a shear handle 2 and a shear joint part, the shear joint part is arc-shaped, and the inside of the shear joint part is provided with A plurality of scissors 3, the scissors 3 are provided with a cutting edge, the outer side of the shearing part is provided with a shaft hole, and the scissor handle 2 is arranged on the outer side of the shearing part. When in use, the scissors 3 are inserted into the fiber tuft, and then the scissor handle 2 is pressed together to cut off the fiber tuft.

[0032] As a further improvement of the above solution, a support rod 4 is provided on the outside of the scissors, and a spring 5 is provided between the support rods 4 . The scissor handle 2 can be automatically restored to the state of preparation before cutting, which increases ease of use and saves operating time.

[0033] As a furt...

Embodiment 3

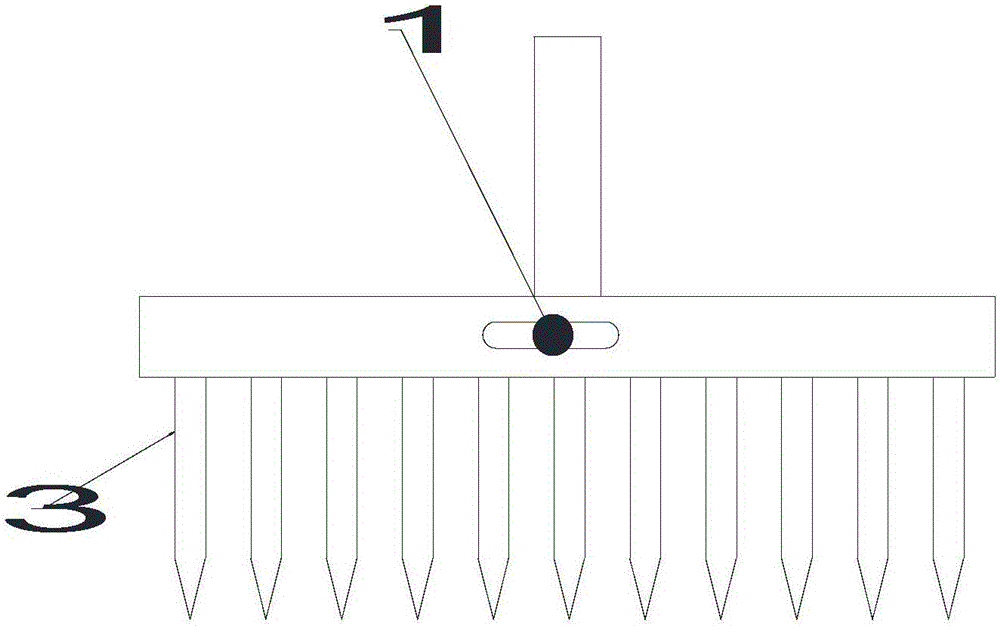

[0038] Embodiment three, refer to Figure 3-4 , a fiber cutting device, including a cutting body and a connecting piece 1, characterized in that: the two cutting bodies are used in combination, the cutting body includes a shearing handle 2 and a cutting part, and a groove 7 is provided on one side of the cutting part And convex key 8, described cutting body is provided with bar-shaped hole 9, and described connector 1 passes through bar-shaped hole 9 and connects two cutting bodies, and the lower part of described shearing part is provided with scissors 3, and described scissors 3 There are cutting edges on the left and right sides. This device can be used on large equipment. When in use, the shearing teeth 3 of the two shears are combined one by one, and then the fiber clusters are inserted. Move to the wrong direction, return to the original state, complete the second cutting, and then repeat the above steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com