Novel perforating machine

A punching machine, a new type of technology, applied in the direction of metal processing, etc., can solve the problems that the tool cannot be replaced, the gasket cannot be moved, the structure is unreasonable, etc., and achieve the effect of convenient chip removal, simple structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

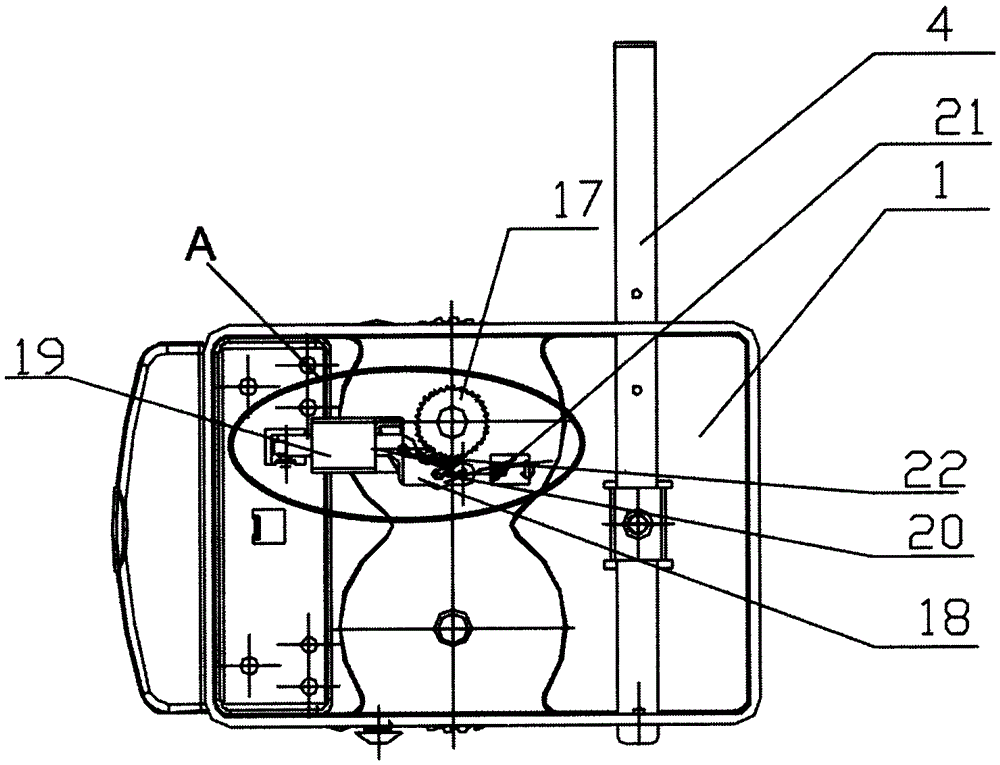

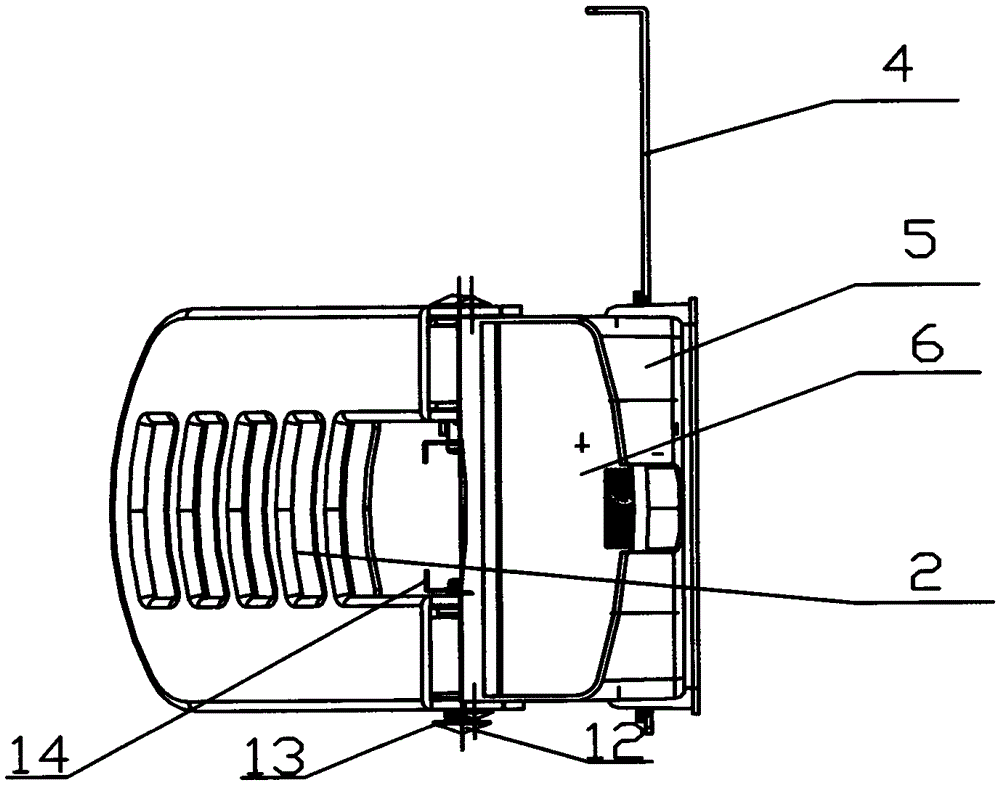

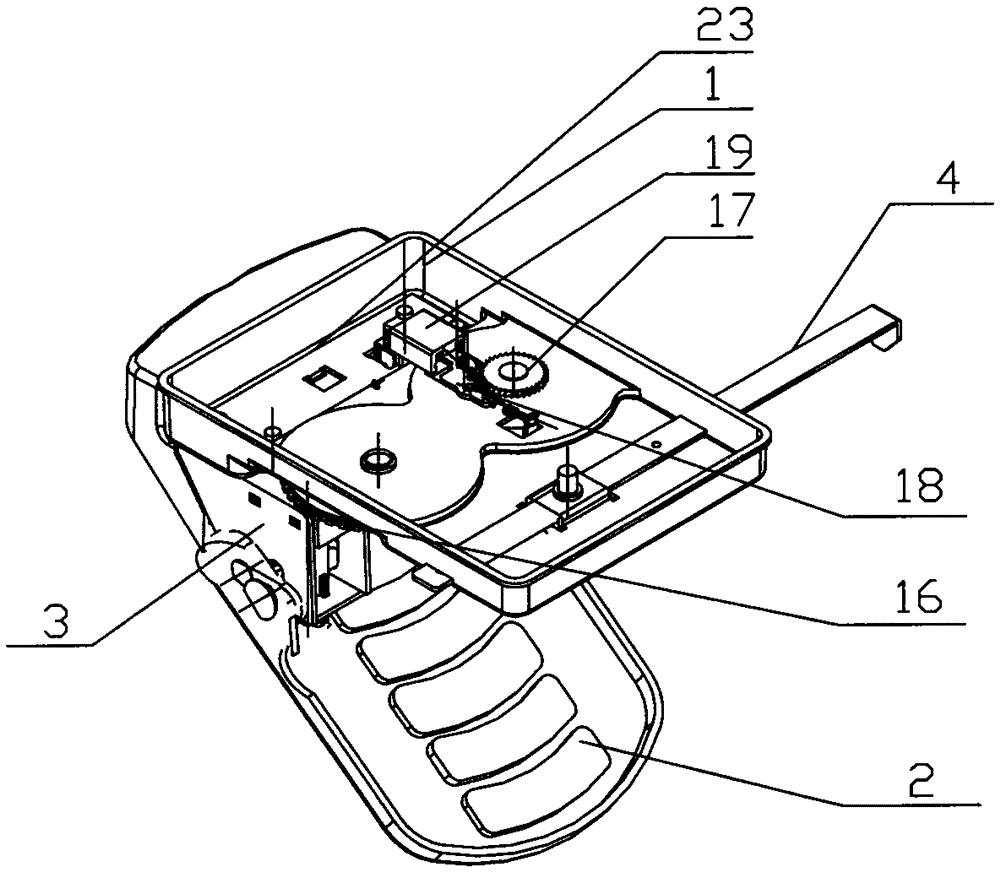

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Embodiments of the present invention refer to Figure 1 to Figure 7 As shown, a new type of punching machine is mainly composed of a base 1, a handle 2, a cutter, a scale rod 4, a scrap box 5, a scrap box cover 6, a bracket 3 and a compression spring 10. The bracket 3 is divided into left and right sides. , the right two brackets, the bracket 3 is connected to the base 1 through bolts and backing plates 23, the handle 2 is connected to the bracket 3 through a short pin shaft, and the short pin shaft connecting the handle 2 and the bracket 2 is externally connected There is a clip spring 10, and the scale rod 4 is plugged into the upper front end of the base 1, and the middle position of the base 1 where the scale rod is inserted is provided with a scale rod top bead, and the scale rod 4 is provided with a ball corresponding to the scale rod top b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com