Log sawing machine for correcting position deviation

A sawing machine and deviation technology, applied in circular saws, sawing equipment, wood processing appliances and other directions, can solve the problems of unfavorable long-term development of enterprises, large cutting allowance, easy deviation, etc., to improve cutting efficiency and cutting efficiency. Accuracy, improve production efficiency, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

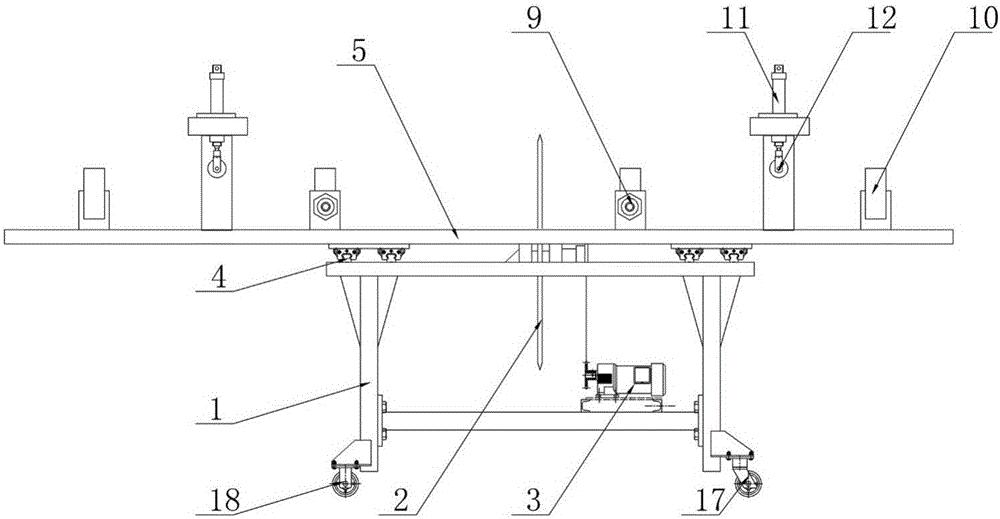

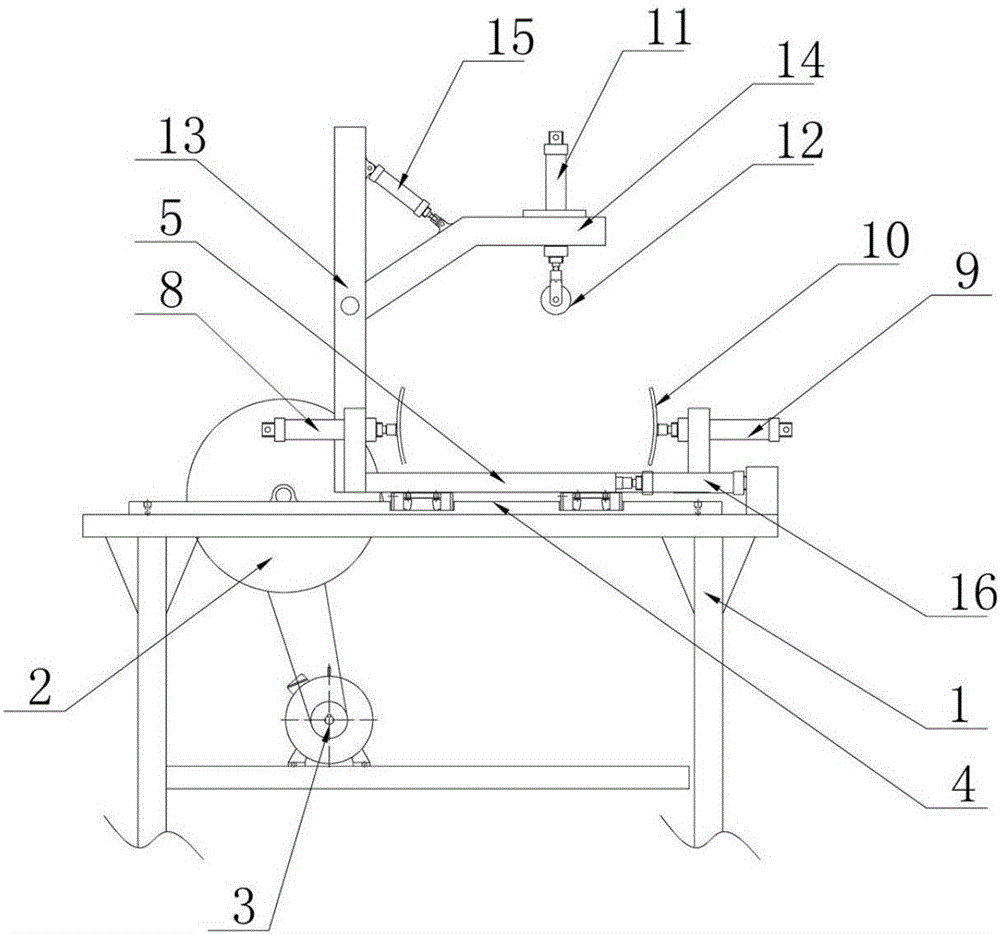

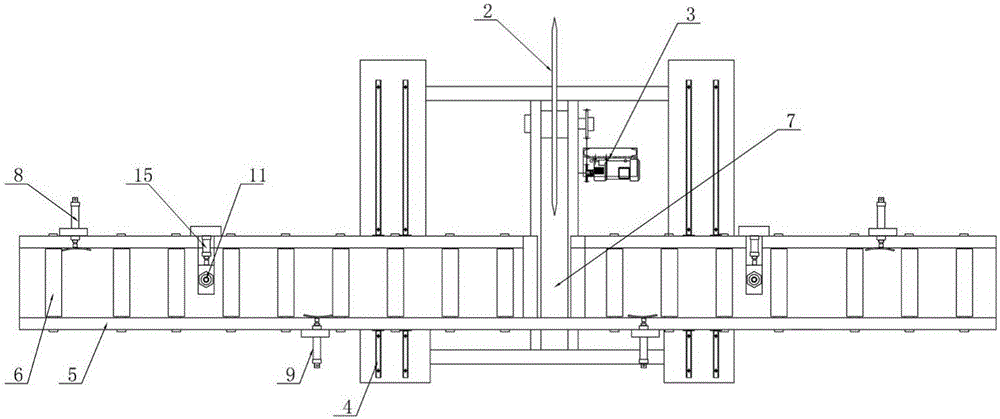

[0016] see Figure 1-Figure 3 , a sawing machine for position deviation correction, comprising a frame 1, a cutting saw blade 2 pivotally arranged on the frame 1 through a rotating shaft, and a driving motor 3 for driving the rotating shaft, the machine on both sides of the cutting saw blade The frame is provided with a feed rail 4, and the feed rail 4 is provided with a discharge rack, and the discharge rack includes a discharge rack body 5, an unpowered transfer roller 6 arranged in the discharge rack body, and a cutting The cutting groove 7 corresponding to the saw blade is provided with two sets of clamping and correcting mechanisms on the discharge rack body, and the clamping and deviation correcting mechanisms include left jacking cylinders 8 and 8 respectively arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com