Electric planer with heat dissipation function

A technology of electric planing and function, which is applied in the direction of manufacturing tools, wood processing appliances, and processing machines for manufacturing flat surfaces. It can solve the problems of electric planing, high temperature, and processing effects, etc., and achieve strong power, prevent splashing, and cool down. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

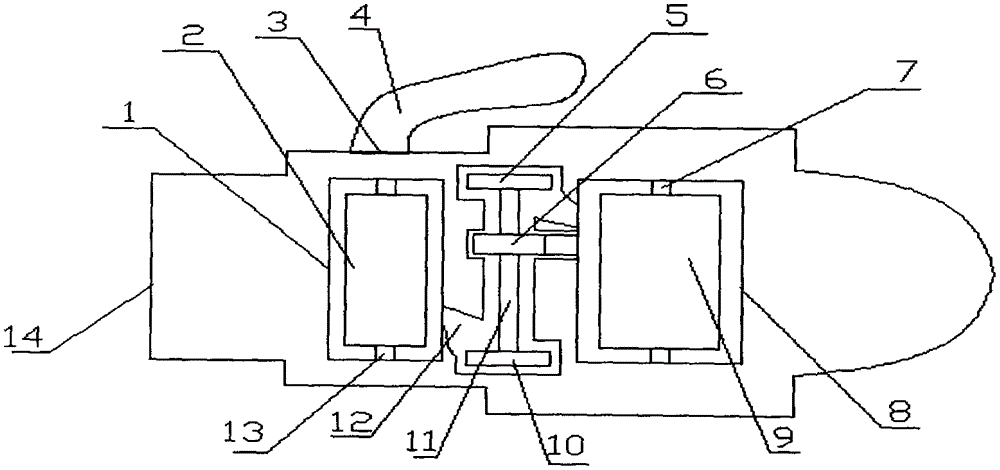

[0012] Such as figure 1 As shown, the present invention discloses an electric planer with a heat dissipation function, comprising a housing 14, a motor structure 9, a cutter body structure 2, an air duct 12 and a fan, and the motor structure 9 and the cutter body structure 2 pass through two mutually parallel The shaft A7 and the shaft B13 are respectively arranged in the cavity A8 and the cavity B1 in the casing 14, and the two are connected by a pulley; the fan is fixed between the cavity A8 and the cavity B1, and the fan passes through the air duct 12 communicates with the cavity A8 or the cavity B1; the fan is fixed on the housing 14 through an axis C11 parallel to the axis A7; the fan includes the fan A5 located at the left end of the axis C11 and the fan B10 located at the right end of the axis C11 , the fan A5 is connected to the cavity A8 through the air duct 12 , and the fan B10 is connected to the cavity B1 through the air duct 12 .

[0013] In order to ensure a goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com