Water hyacinth salvage ship

A technology for salvaging boats and water hyacinths, which is applied to water conservancy projects, special-purpose vessels, and cleaning of open water surfaces. It can solve the problems of low salvage efficiency, requiring many workers, and high power consumption. The effect of increasing the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

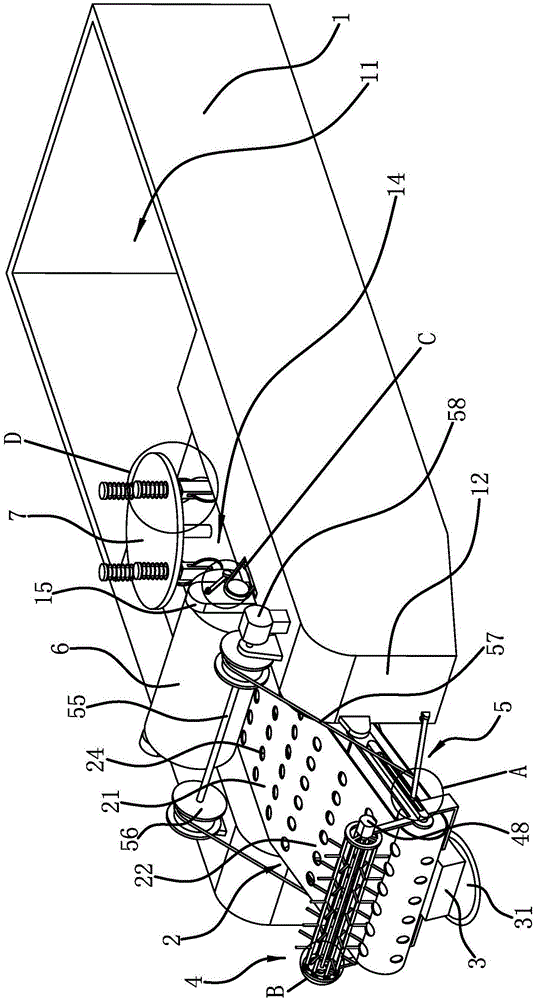

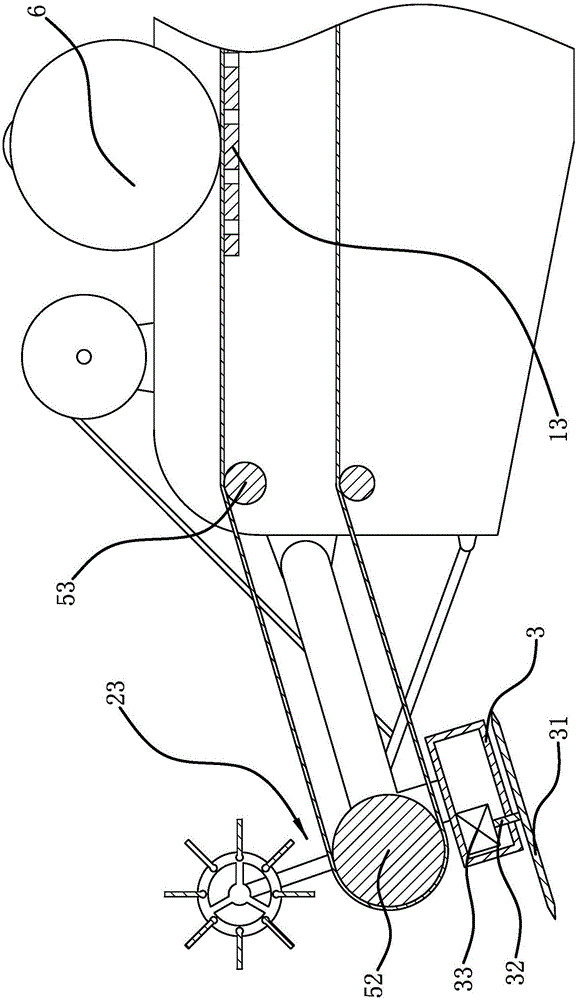

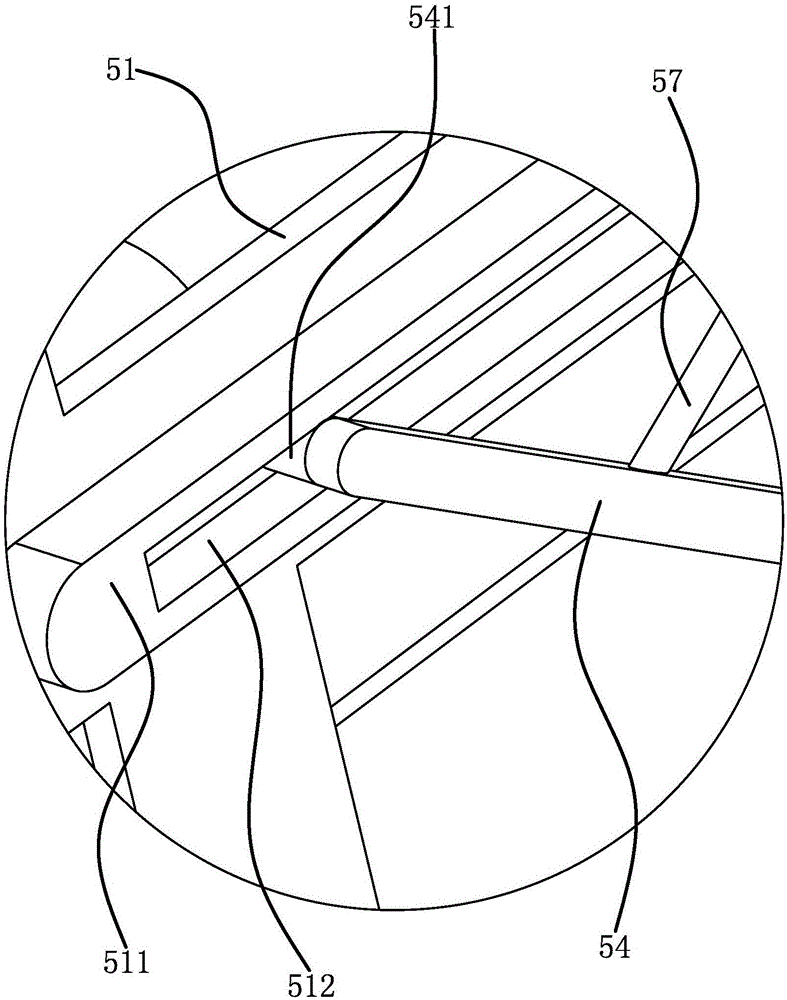

[0028] Such as Figure 1 to Figure 8 As shown, a water hyacinth salvage ship includes a hull 1 with a collection cabin 11 on the hull 1. The front end of the hull 1 has two elongated installation parts 12 protruding forward, and there is a gap between the two installation parts 12. A conveyor belt 2 is connected between the two installation parts 12 along the forward and backward direction of the hull 1. The conveyor belt 2 includes a horizontal filter section 21 and a feed section 22 positioned at the front end of the filter section 21 and capable of swinging up and down. The front end of the feed section 22 is rotatably connected with a Cutter 31, the cutting edge of the cutter 31 protrudes from the end of the feed secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com