Connection structure and fatigue control method of fpso upper module under motion constraints

A module connection and motion constraint technology, which is applied to ship components, floating buildings, transportation and packaging, etc., can solve the problems of upper module deformation or tearing, insignificant cushioning effect, and fatigue cracks at the connection, so as to overcome the connection strength Weak, simple design, less difficult to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

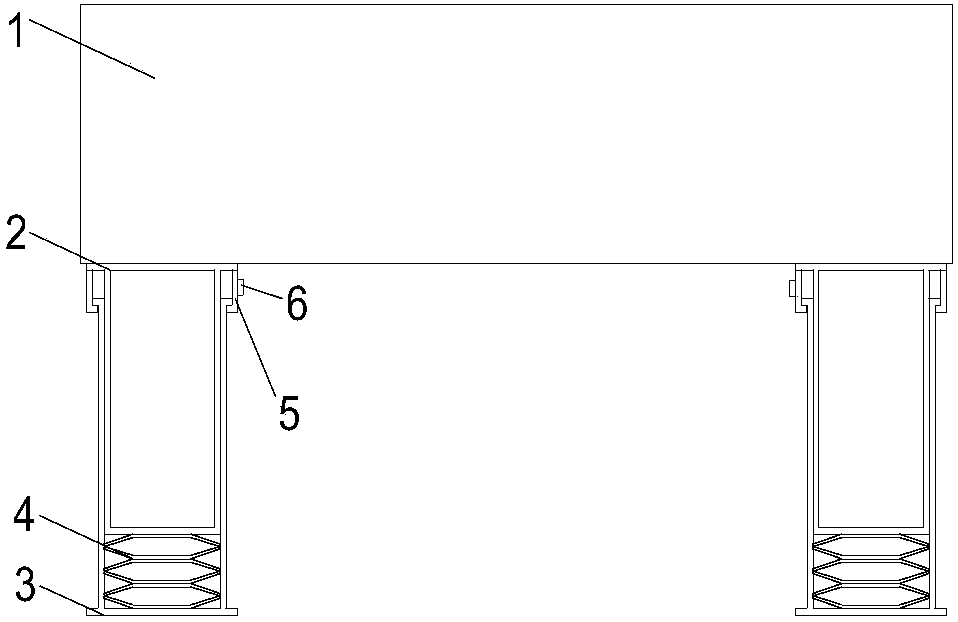

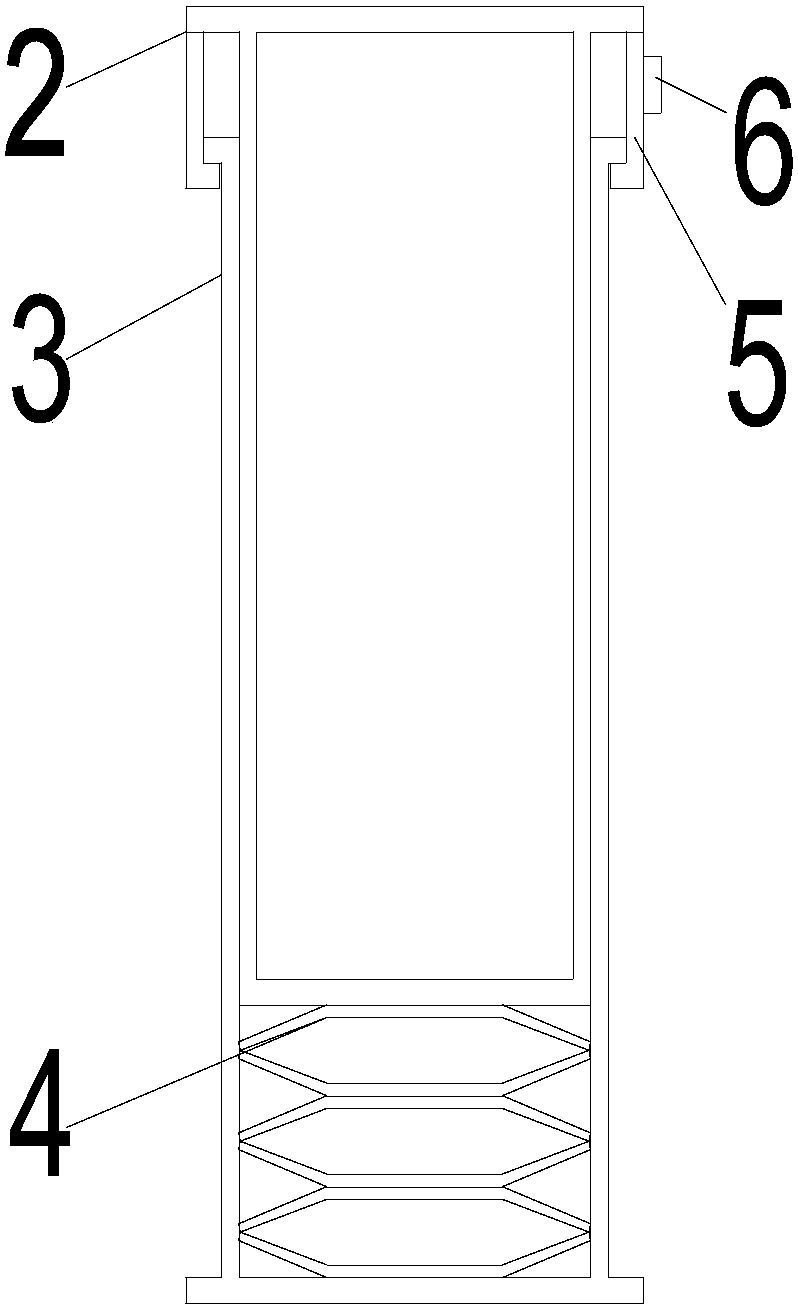

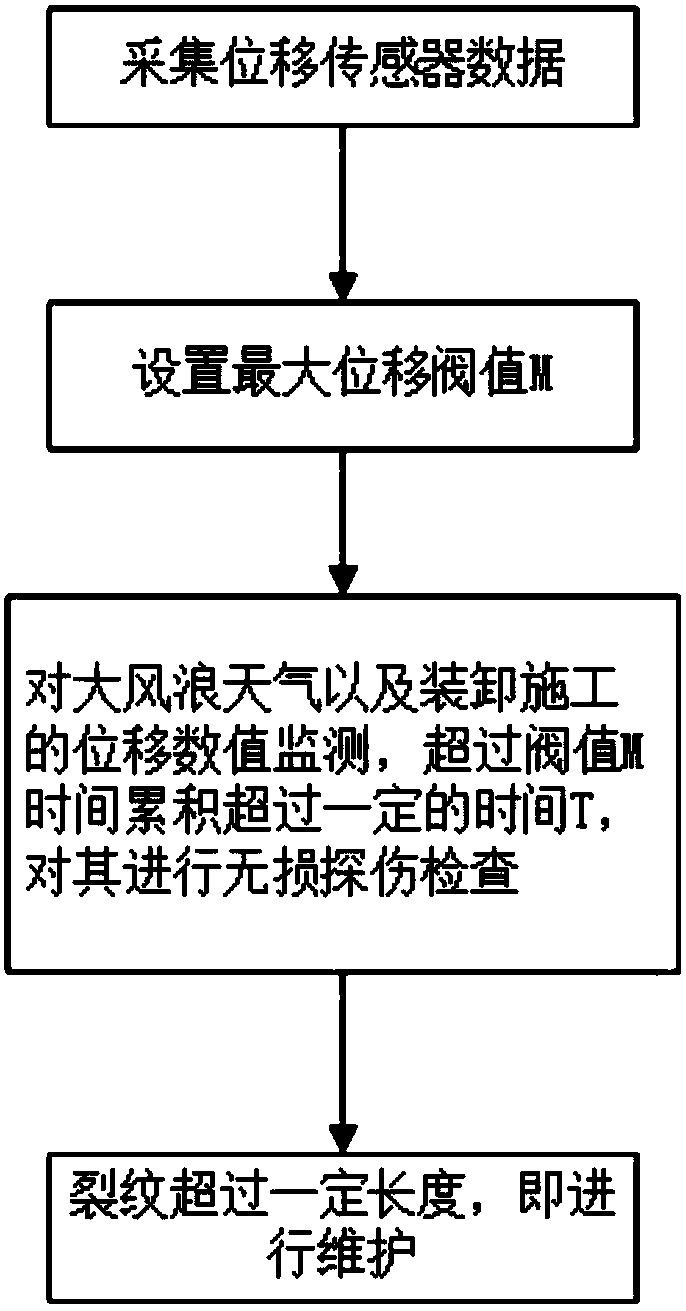

[0014] The connection structure of the upper module of the floating production, storage and offloading unit under movement constraints as shown in the accompanying drawing includes a plurality of hollow rectangular lower legs 3, and each of the lower legs 3 is welded on the main deck of the hull , a plurality of disc springs 4 are arranged on the bottom wall of the cavity of each of the lower legs, and the plurality of disc springs 4 are matched with the cavity of the lower legs, and a plurality of hollow The rectangular upper legs 2 are respectively inserted into the cavities of the lower legs in one-to-one correspondence, and the bottom wall of the upper legs 2 is supported on the Belleville springs, the upper legs 2 and the lower legs Cavity clearance fit. There is an ear plate extending outward around the upper opening of the lower leg 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com