Processing method of high-cool-sense polyester sofa fabric

A processing method and fabric technology, applied in textiles, biochemical fiber treatment, fabrics, etc., to achieve the effect of improving coolness, increasing coolness, and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

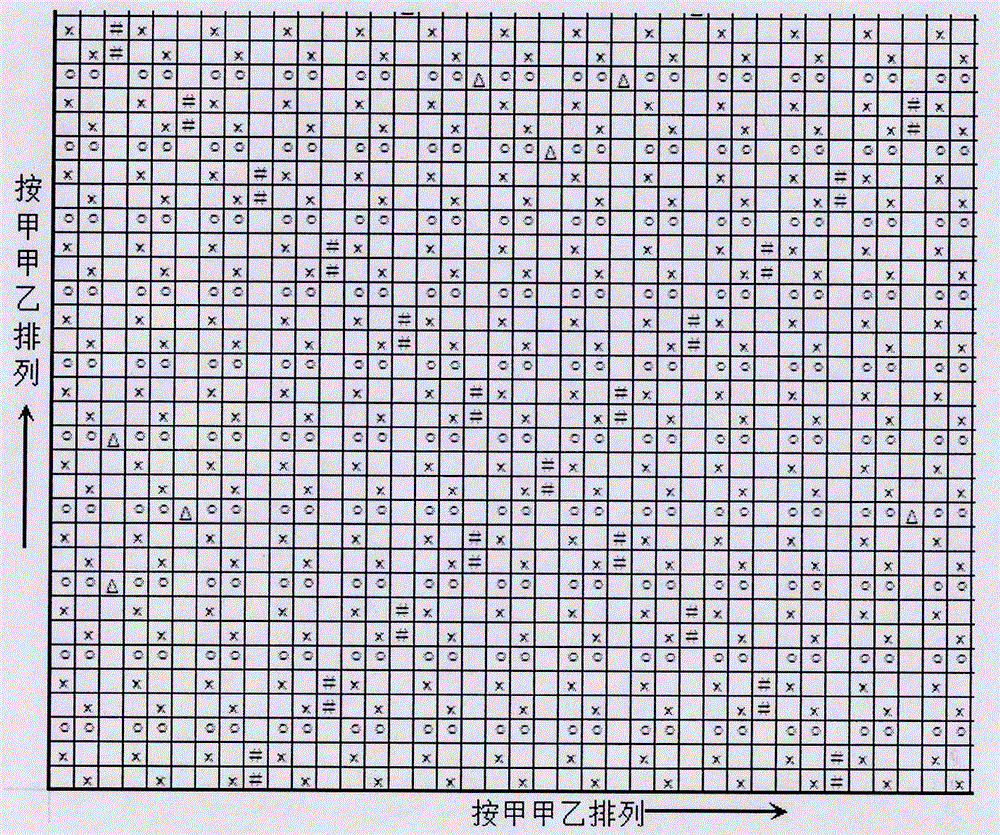

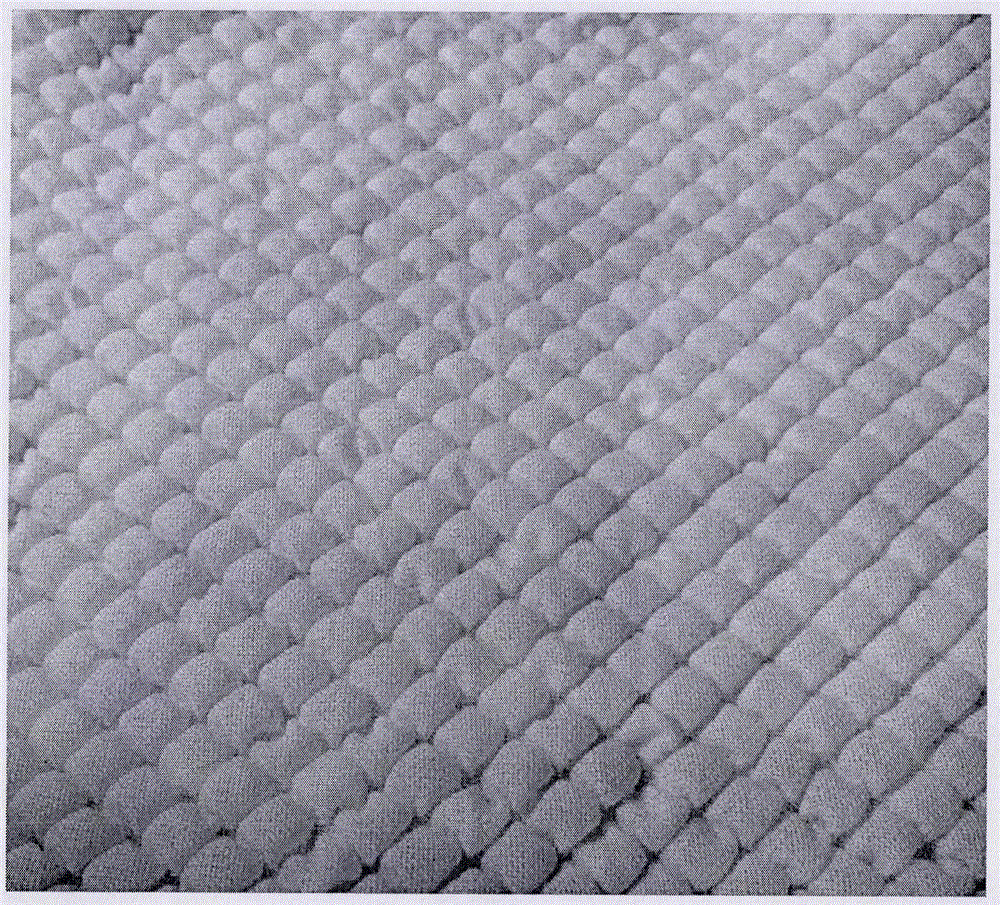

[0022] Put the warped looms 1 and 2 into the front end of the loom, adjust the warp tension of the upper layer to 150N, the tension of the lower sheet yarns to 225N, adjust the weft insertion rate to 600 in / min, and configure the weft yarns according to the weave of the upper layer It is a plain weave, and the underlying organization is a variable square weave. After the weaving is completed, the fabric is placed in a drying oven at 70°C for setting treatment. Then the cloth roll was put into the magnetron plasma deposition equipment, magnesium was used as the target material, and the functionalization was carried out under the process parameters of a pressure of 2.5 Pa, a power of 150 watts, and a sputtering time of 20 minutes. The obtained fabric is a polyester sofa fabric with a high cool feeling.

Embodiment example 2

[0024] Put the warped looms 1 and 2 into the front end of the loom, adjust the warp tension of the upper layer to 170N, the tension of the lower sheet yarn to 255N, adjust the weft insertion rate to 600 in / min, and configure the weft according to the weave of the upper layer It is a plain weave, and the underlying organization is a variable square weave. After the weaving is completed, the fabric is placed in a drying oven at 70°C for setting treatment. Then the cloth roll was put into the magnetron plasma deposition equipment, magnesium was used as the target material, and the functionalization was carried out under the process parameters of a pressure of 2.5 Pa, a power of 150 watts, and a sputtering time of 20 minutes. The obtained fabric is a polyester sofa fabric with a high cool feeling.

Embodiment example 3

[0026] Put the warped looms 1 and 2 into the front end of the loom, adjust the warp tension of the upper layer to 200N, the tension of the lower sheet yarn to 300N, adjust the weft insertion rate to 600 in / min, and configure the weft yarn according to the weave of the upper layer It is a plain weave, and the underlying organization is a variable square weave. After the weaving is completed, the fabric is placed in a drying oven at 70°C for setting treatment. Then the cloth roll was put into the magnetron plasma deposition equipment, magnesium was used as the target material, and the functionalization was carried out under the process parameters of a pressure of 2.5 Pa, a power of 150 watts, and a sputtering time of 20 minutes. The obtained fabric is a polyester sofa fabric with a high cool feeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com