Small piping cramming device

A technology of small tubes and spheres, applied in water conservancy projects, sea area projects, construction, etc., can solve problems such as low efficiency, poor channel blockage effect, and delay in the best time for blocking, achieving simple structure and improving plugging effect , fast and reliable plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

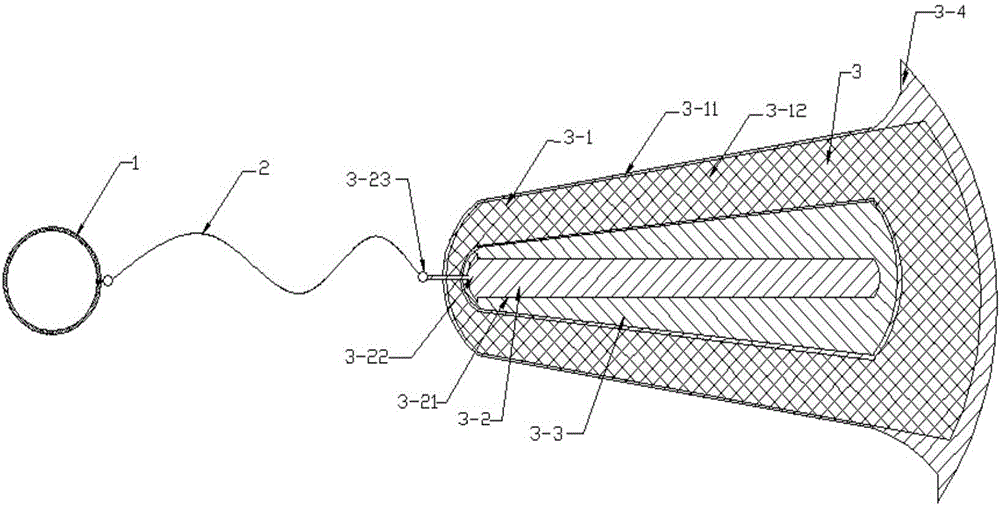

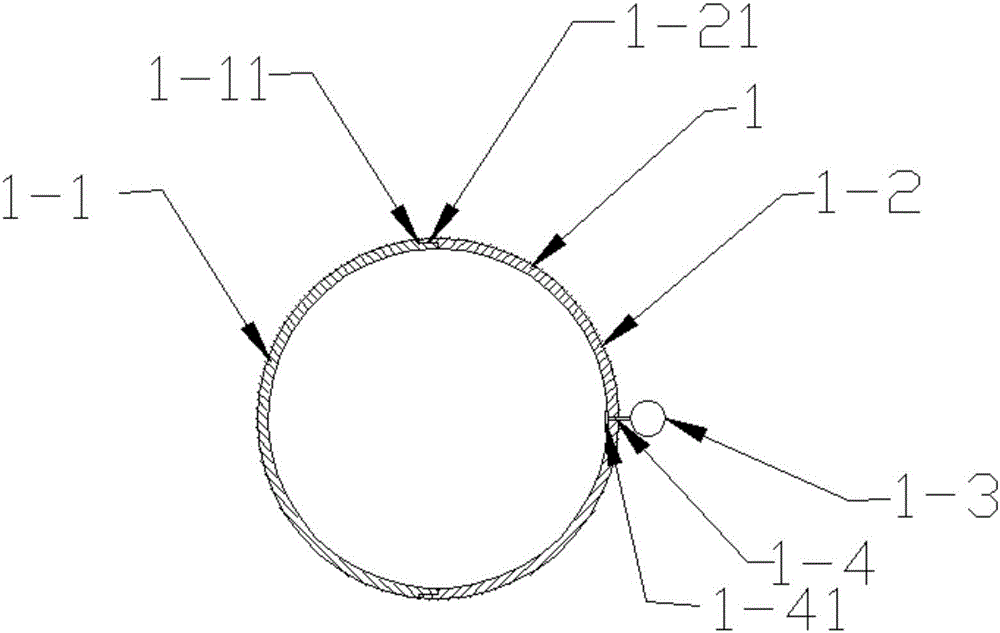

[0015] Embodiment 1: as Figure 1-2 As shown, the present embodiment provides a small pipe plugging device, including a steel hollow ball 1, a high-strength fiber cable 2, and a plug body 3, and the plug body 3 includes a jellyfish outer layer 3-1, and an alloy pillar 3-2 , hard rubber plug body 3-3, the steel hollow ball 1 includes a left sphere 1-1, a right sphere 1-2, a first pull ring 1-3, a first pull ring rod 1-4, the left The sphere 1-1 is provided with an external thread 1-11, the right sphere 1-2 is provided with an internal thread 1-21 corresponding to the external thread 1-1, and one end of the first pull ring rod 1-4 is provided with There is a first pull ring 1-3, the other end extends into the inside of the right sphere 1-2 and a stopper 1-41 is provided at the end, the surface of the alloy pillar 3-2 is provided with a thread 3-21, and the alloy pillar 3-2 The left end is provided with a stopper 3-22, and the second pull ring 3-23 is arranged on the stop block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com