Automatic clearing method for water body floating objects at hydraulic sluice

An automatic cleaning and floating debris technology, which is applied in the cleaning of open water, water conservancy projects, construction, etc., can solve the problems of high cost, high risk, and full cleaning speed of salvage ships, and achieve the effect of convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

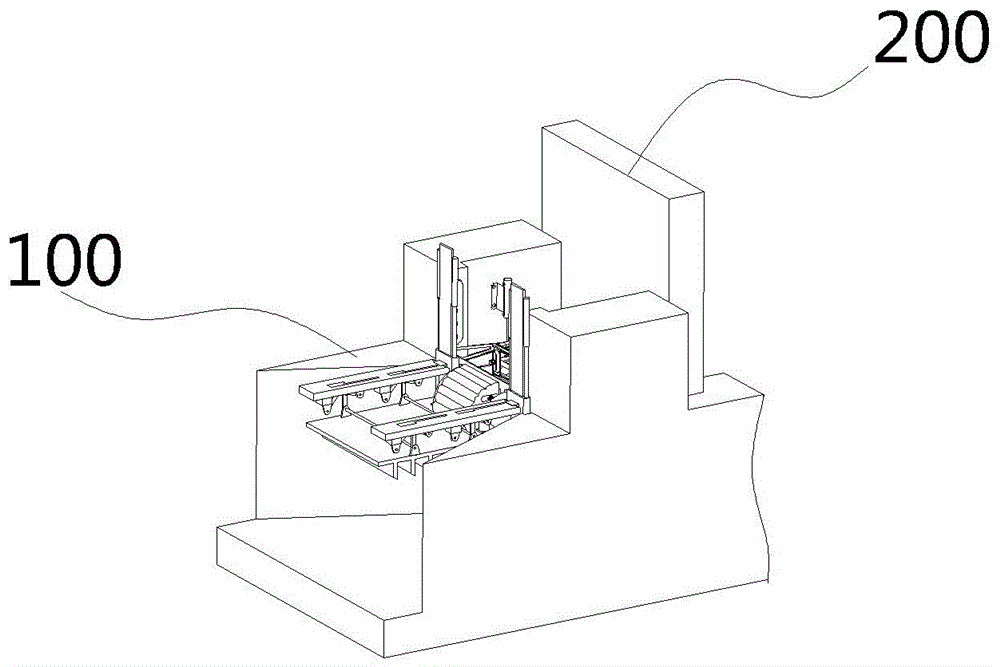

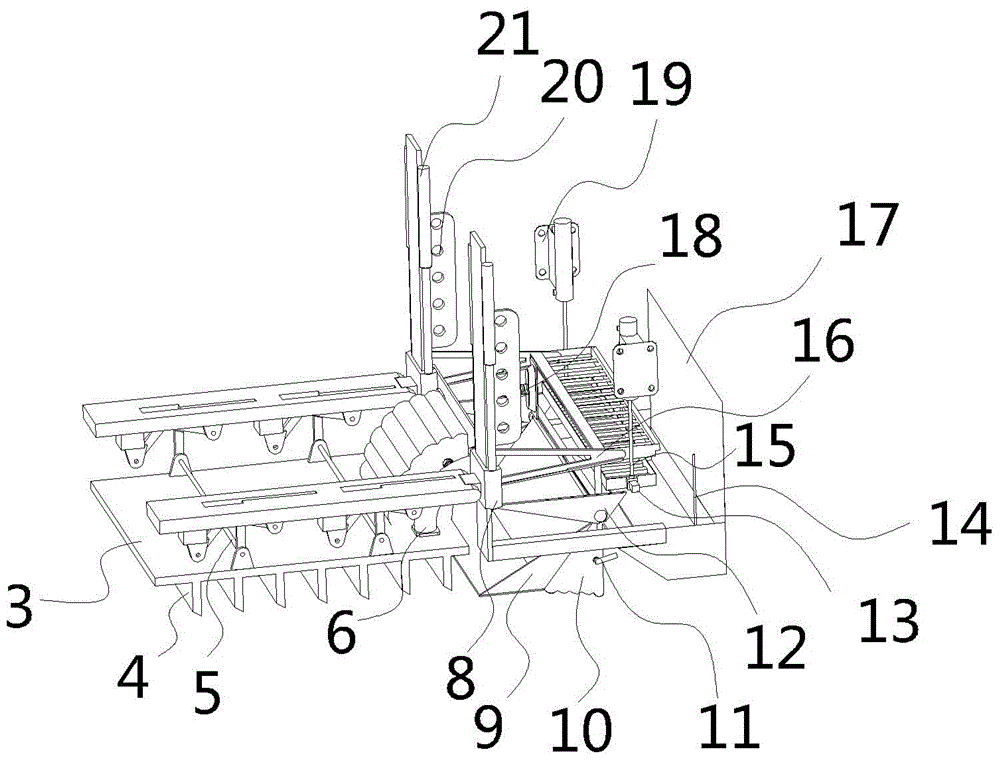

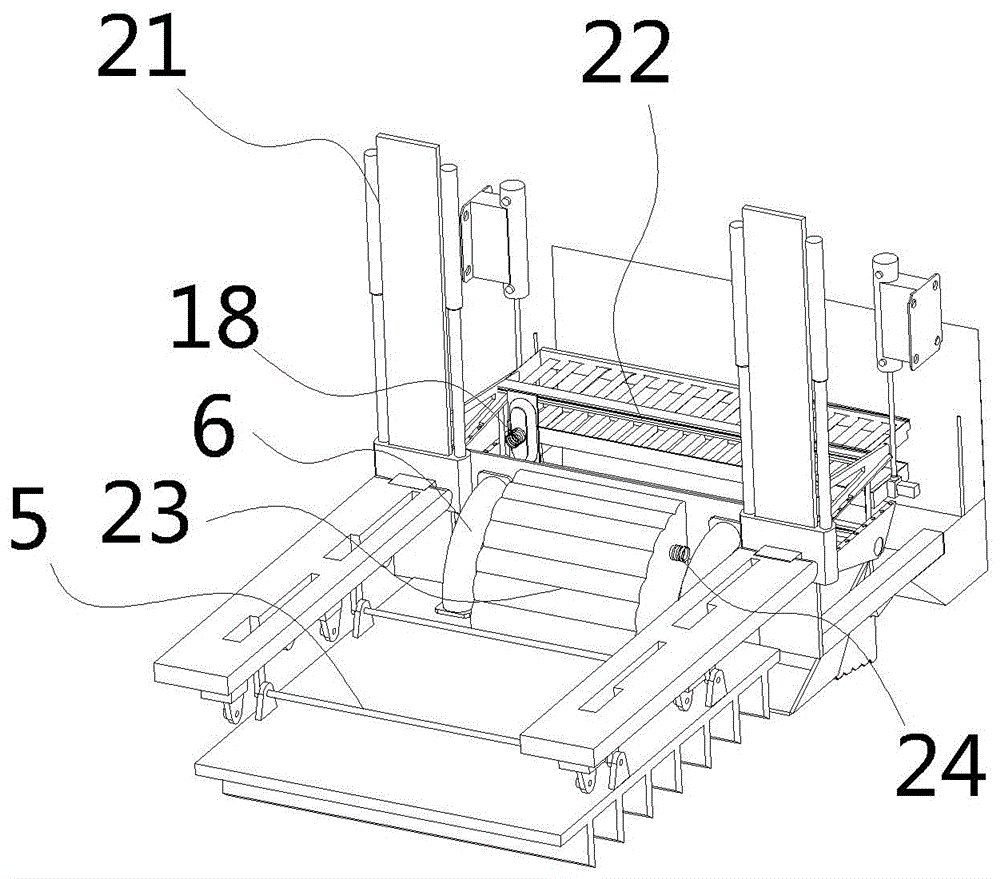

[0030] As shown in the figure, the automatic cleaning device for floating objects in the water body at the water conservancy sluice includes a dam body 100, the dam body 100 is equipped with a sluice 100, and a fixed bracket 20 is arranged symmetrically in front of the sluice 100, and then the dam body 100 is installed. Above, the fixed bracket 20 is equipped with a slider 8 driven by a hydraulic cylinder 21 to move up and down, and a horizontal plate is connected between the sliders 8; a fixed plate 27 is hinged on the slider 8 . The hydraulic cylinder one 21 lifts the slide block 8 when the device is not in use, and the fixed plate 27 is also in a parallel state with the fixed bracket one 20 when the device is not in use, so that the stepping mechanism is separated from the water surface, preventing the equipment from being soaked for a long time. damage.

[0031] The active rod 26 driven by the motor to rotate is installed on the fixed plate 27; one end of the passive rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com