Tubular pile sinking simulation test device and method under gradient confining pressure

A simulation test and tubular pile technology, applied in the field of pile foundation and construction engineering, can solve the lack of testing of the dynamic evolution of soil properties around the pile and pile core soil, and the inability to simulate the in-situ stress level and distribution characteristics of natural soil, etc. problem, to achieve the effect of convenient and fast loading and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

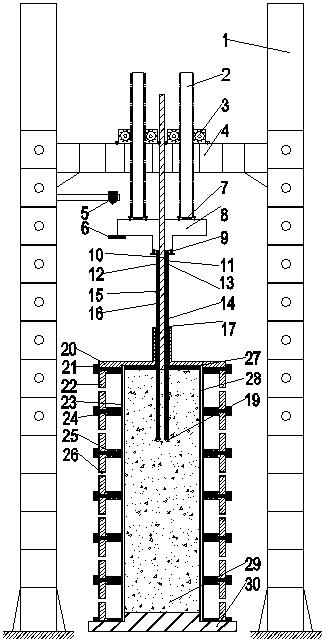

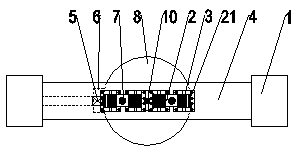

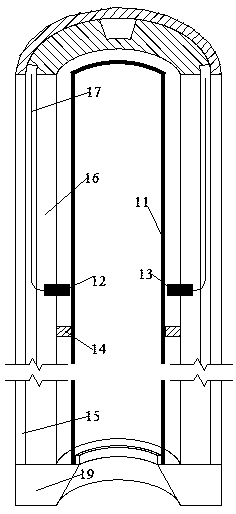

[0043] Such as Figure 1~7 As shown, a pipe pile sinking simulation test device under gradient confining pressure, including a reaction force support frame, a loading device, a wave velocity test device, a model pipe pile, and a confining pressure simulation component;

[0044] The reaction support frame includes a reaction frame 1 and a reaction beam 4, and the reaction beam 4 is vertically arranged in the middle of the reaction frame 1;

[0045] The loading device includes two pairs of driving gears 3, sawtooth pressing rods 2 and pressure bearing plates 8, and the two pairs of driving gears 3 are placed on the reaction force beam 4, the driving gears 3 are controlled by motors, and the sawtooth pressing rods 2 are respectively arranged on the two driving gears. 3, and the sawtooth pressure bar 2 passes through the reaction force beam 4, and the bottom of the sawtooth pressure bar 2 is provided with a pressure bearing plate 8; when loading, the motor is used to drive the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com