Hydraulic-fracturing physical simulation method for horizontal well provided with spiral jet hole

A technology of hydraulic fracturing and physical simulation, which is applied in earthwork drilling, wellbore/well components, production fluids, etc. It can solve the problem of no explanation of the influence of perforation parameters on hydraulic fracturing, no research impact, and no public physical simulation Methods and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

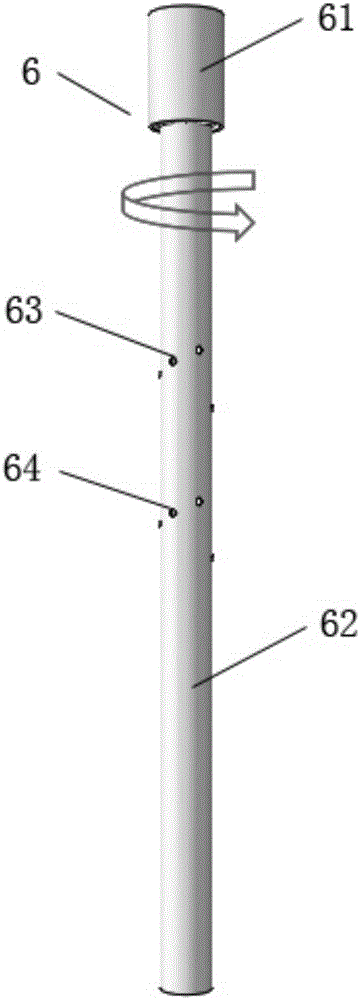

[0083] Such as figure 1 , figure 2 and Figure 13 As shown, according to an embodiment of the hydraulic fracturing physical simulation method with spiral perforation horizontal wells of the present invention, the following steps are included in sequence:

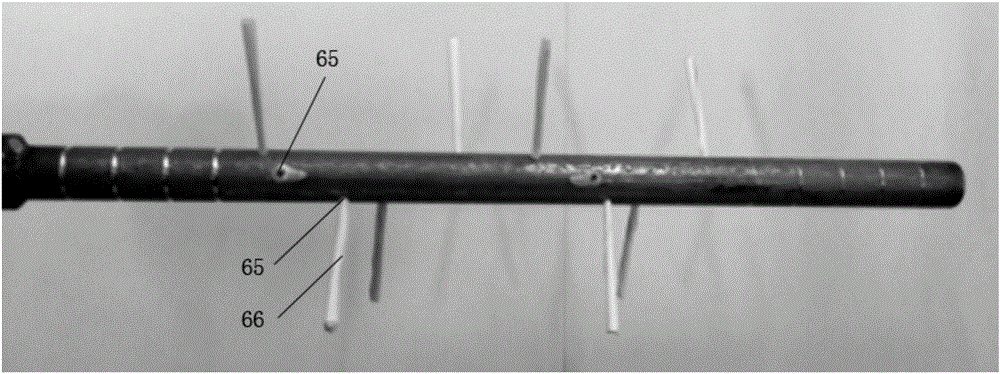

[0084] Step 1: process the simulated wellbore 6, and set spiral perforation holes 65 with different parameter combinations on the well wall of the simulated wellbore 6; make spiral perforation tunnels 66, and insert the spiral perforation tunnels 66 into the spiral perforation holes 65;

[0085] Step 2: Process the test piece mold, open a round hole at the center of the bottom surface of the test piece mold, place the wellbore head 61 of the simulated wellbore 6 in the round hole downwards, and now the simulated wellbore 6 is vertically placed in the test piece mold ;

[0086] Step 3: Mix cement and quartz sand, then add water and stir evenly to form a mixture; pour the mixture into the specimen mold, and remove the spec...

Embodiment 2

[0110] Such as image 3 and Figure 4 As shown, according to another embodiment of the hydraulic fracturing physical simulation method for a horizontal well with spiral perforation of the present invention, its process steps, principles and beneficial effects are all the same as those of the first embodiment.

[0111] In this embodiment, the combination of spiral perforation parameters is as follows: the perforation section includes two clusters of spiral perforation holes 65, the number of spiral perforation holes 65 in each cluster is 6, and there are 12 perforations in the perforation section; the first cluster The distance between the last perforation in the spiral perforation 63 and the first perforation in the second cluster of spiral perforation 64 is 20mm, that is, the cluster spacing is 20mm; two adjacent perforations in each cluster of spiral perforation 65 The vertical distance is 1cm, the angle between two adjacent perforations is 60°, that is, the phase is 60°; t...

Embodiment 3

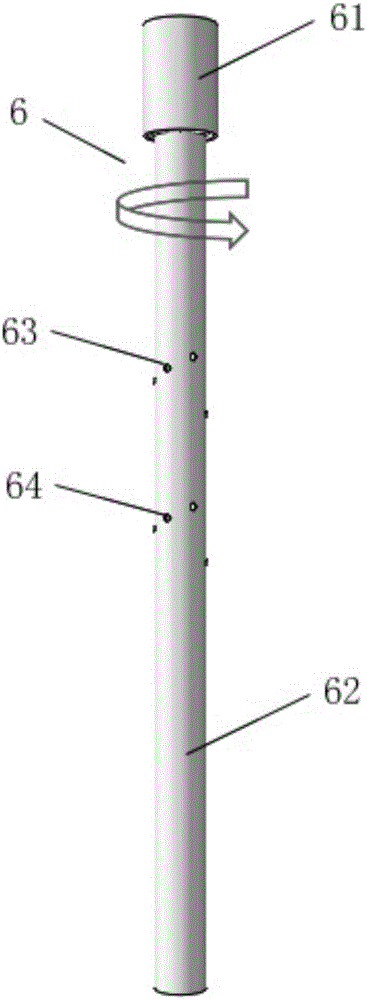

[0114] Such as Figure 5 and Figure 6 As shown, according to another embodiment of the hydraulic fracturing physical simulation method for a horizontal well with spiral perforation of the present invention, its process steps, principles and beneficial effects are all the same as those of the first embodiment.

[0115] In this embodiment, the combination of spiral perforation parameters is as follows: the perforation section includes two clusters of spiral perforation holes 65, the number of spiral perforation holes 65 in each cluster is 6, and there are 12 perforations in the perforation section; the first cluster The distance between the last perforation in the spiral perforation 63 and the first perforation in the second cluster of spiral perforation 64 is 20mm, that is, the cluster spacing is 20mm; two adjacent perforations in each cluster of spiral perforation 65 The vertical distance is 1cm, the angle between two adjacent perforations is 60°, that is, the phase is 60°; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com