Moveable trestle with stepping type self-walking truss structure for large-section tunnel invert construction

A technology of truss structure and mobile trestle, applied in tunnels, tunnel linings, pedestrian bridges, etc., can solve the problems of difficult movement, small distance, cumbersome structure, etc., and achieve the effect of good operation synchronization, high equipment efficiency, and reduced equipment weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The invention will be further introduced below in conjunction with the drawings and specific embodiments:

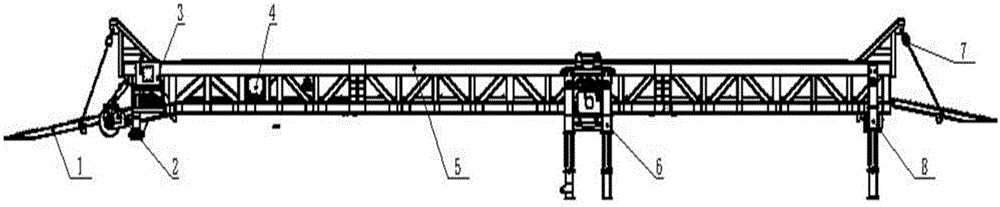

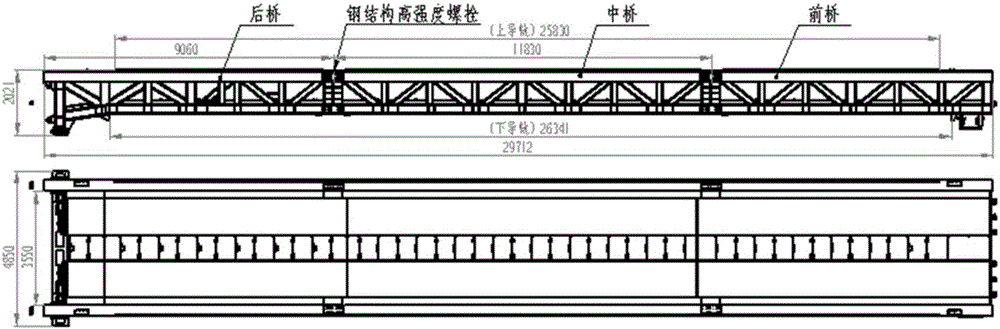

[0041] Such as Figure 1-11 As shown, a stepping self-propelled truss structure mobile trestle for large section tunnel invert construction, including approach bridge 1, drive wheel 2, hydraulic system 3, electrical system 4, main bridge body 5, stepping mechanism 6, electric hoist 7 The main axle body 5 is composed of three sections of front axle, middle axle and rear axle. The front axle, middle axle and rear axle are all connected by steel structure high-strength bolts; The actions of mechanism 6 are all controlled by the remote controller.

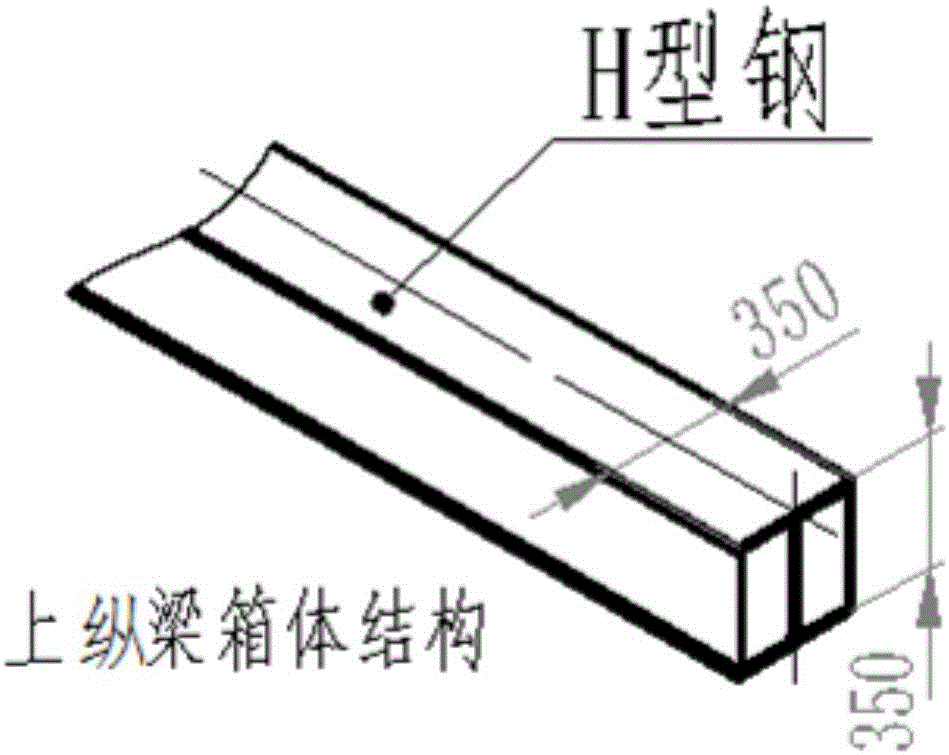

[0042] Further, the main body of the inverted arch trestle is the main force-bearing part of the entire trestle to realize its functions. The combined structure of box girder and truss is adopted for force analysis and optimization. The overall length of the main bridge is nearly 30 meters, in order to facilitate transportatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com