Patents

Literature

31results about How to "Equipment efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

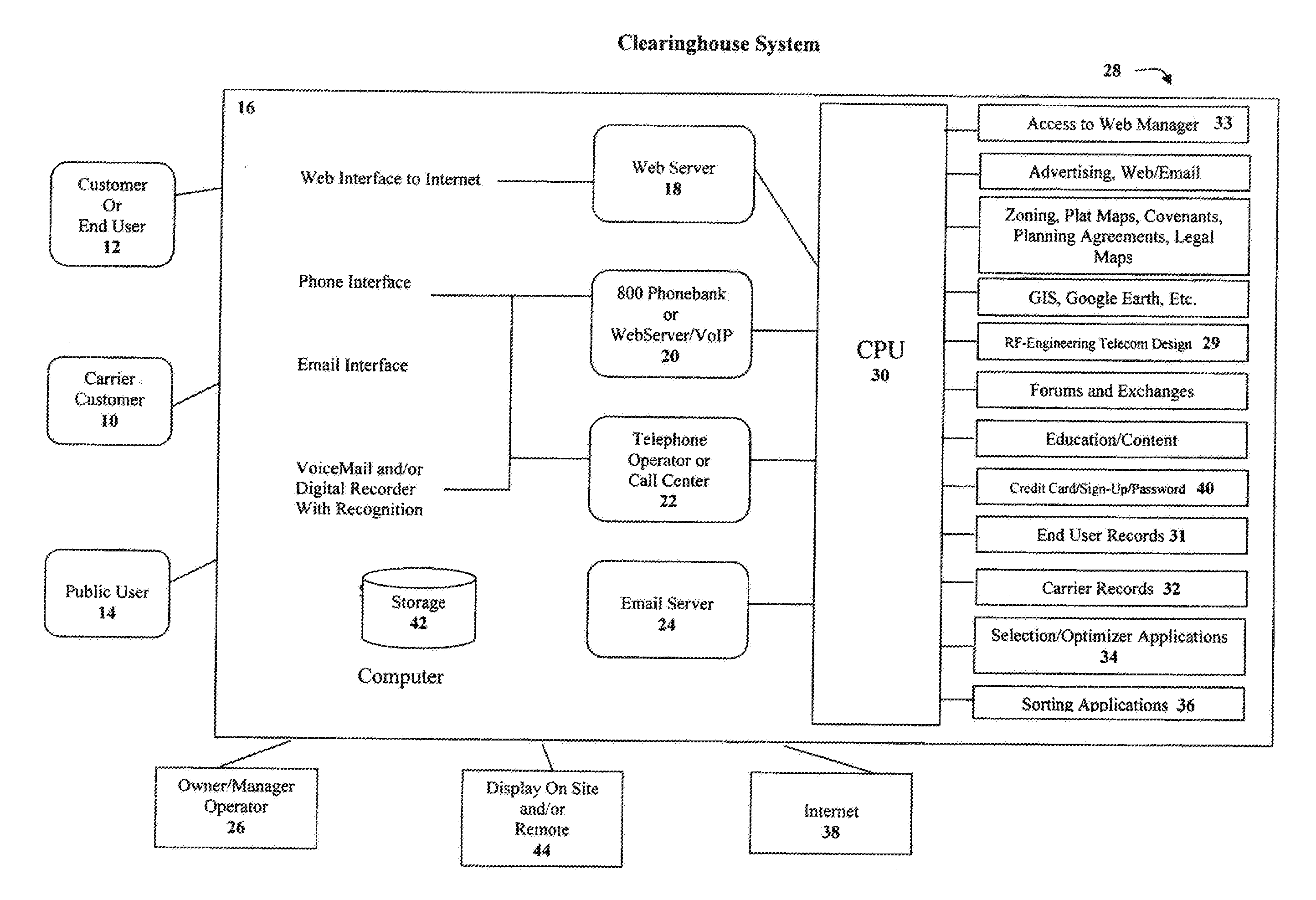

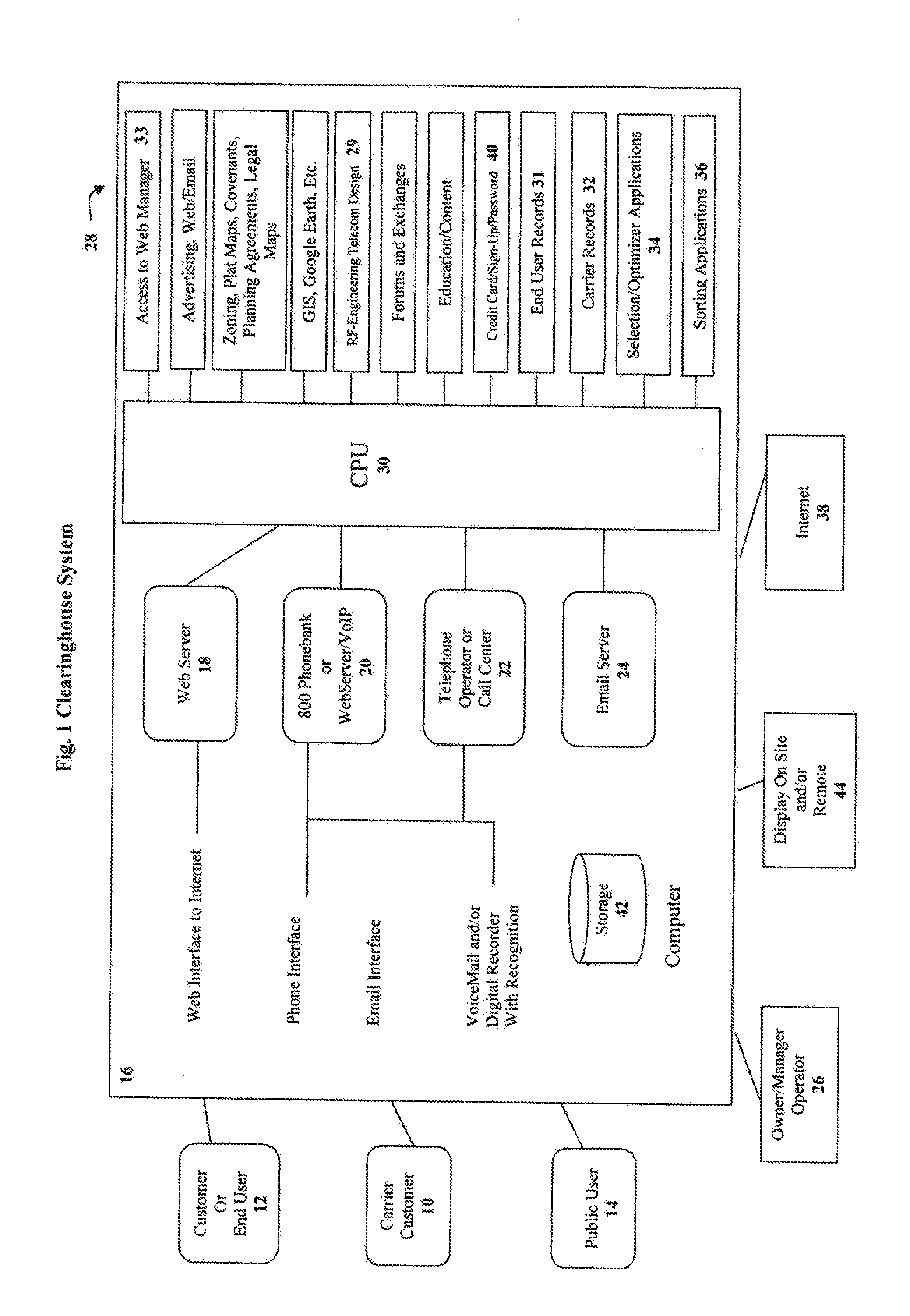

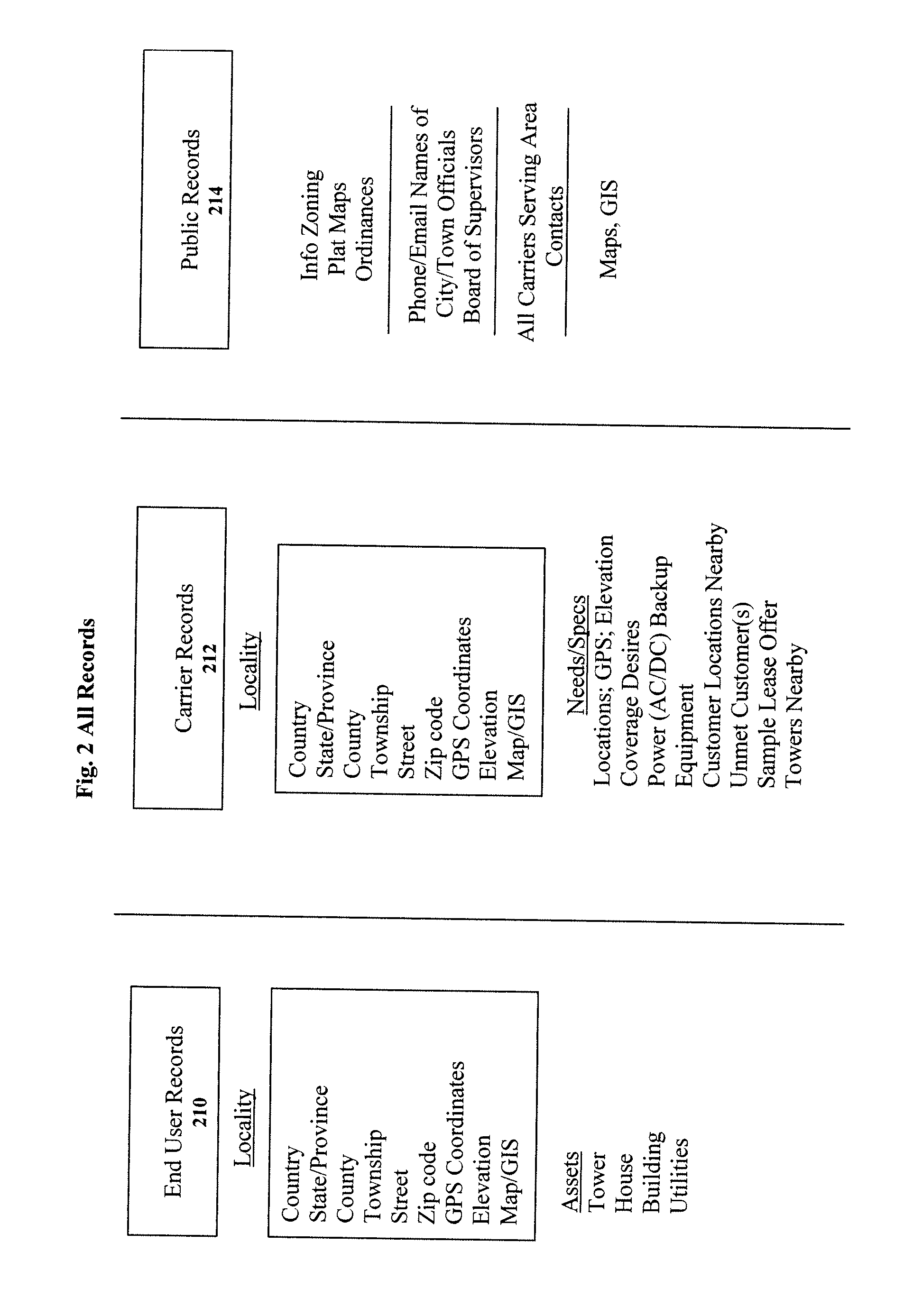

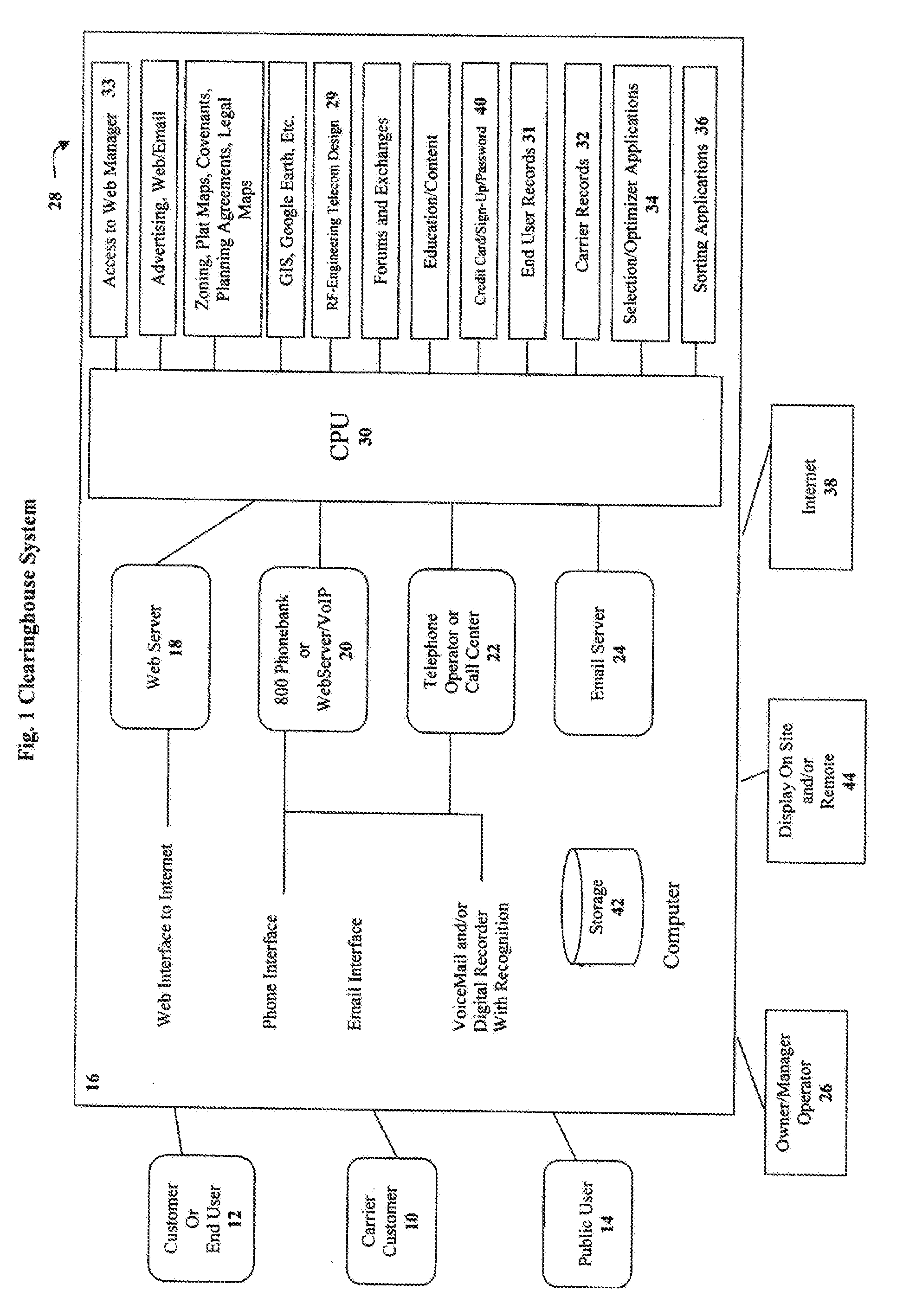

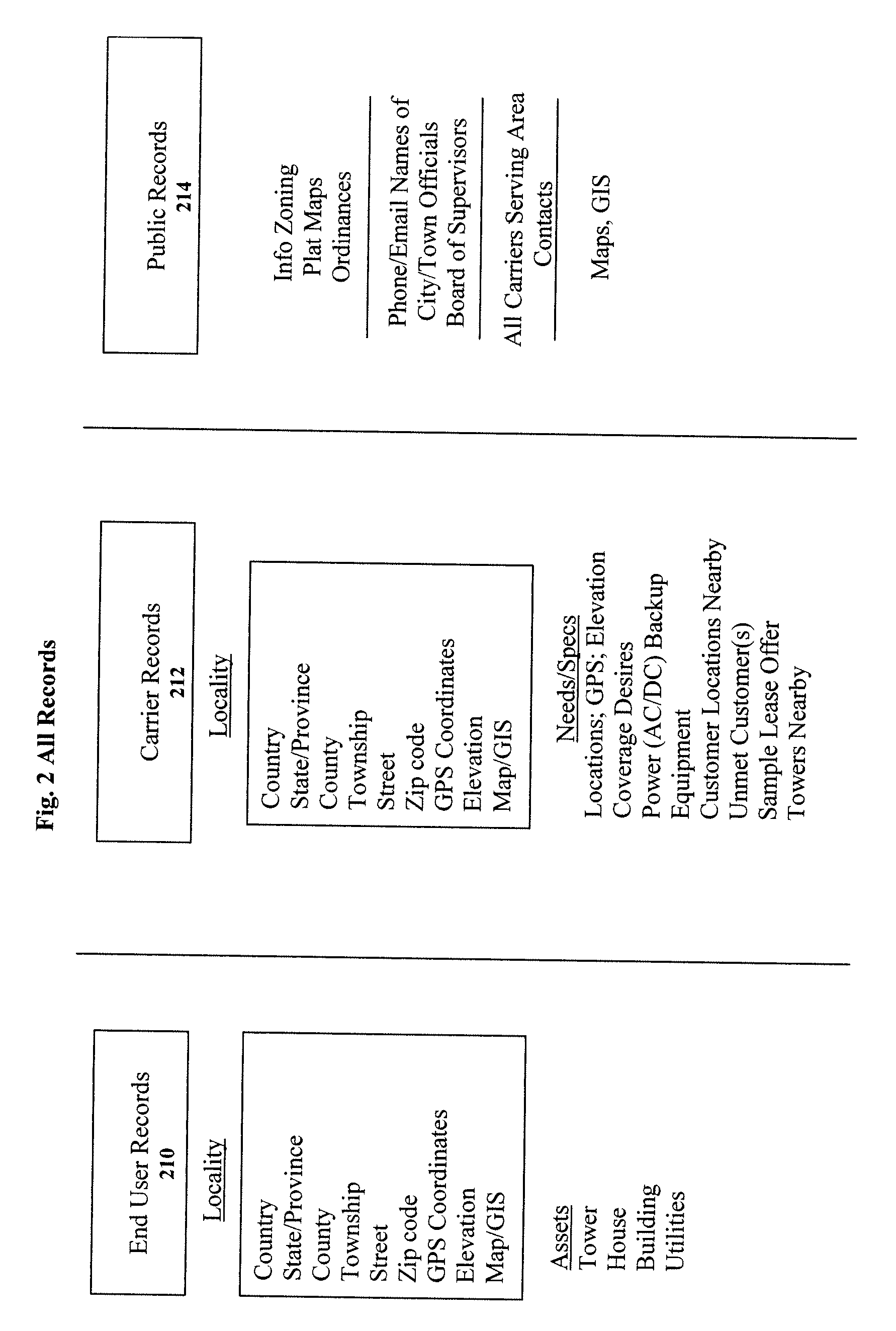

Clearinghouse system, method, and process for inventorying and acquiring infrastructure, monitoring and controlling network performance for enhancement, and providing localized content in communication networks

ActiveUS20090070379A1Broaden their knowledgeLow costError detection/correctionMultiple digital computer combinationsCommunications systemTelecom network

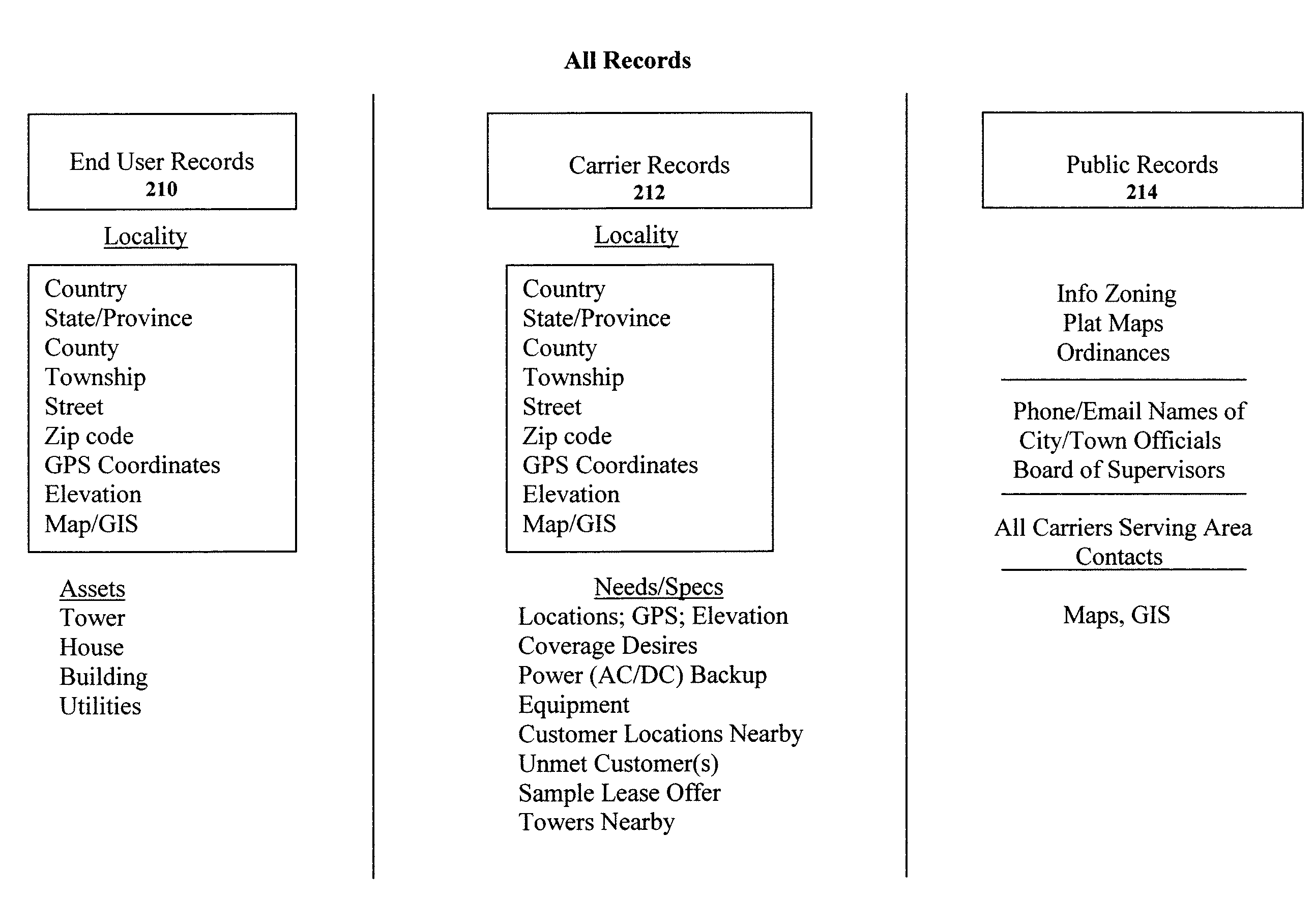

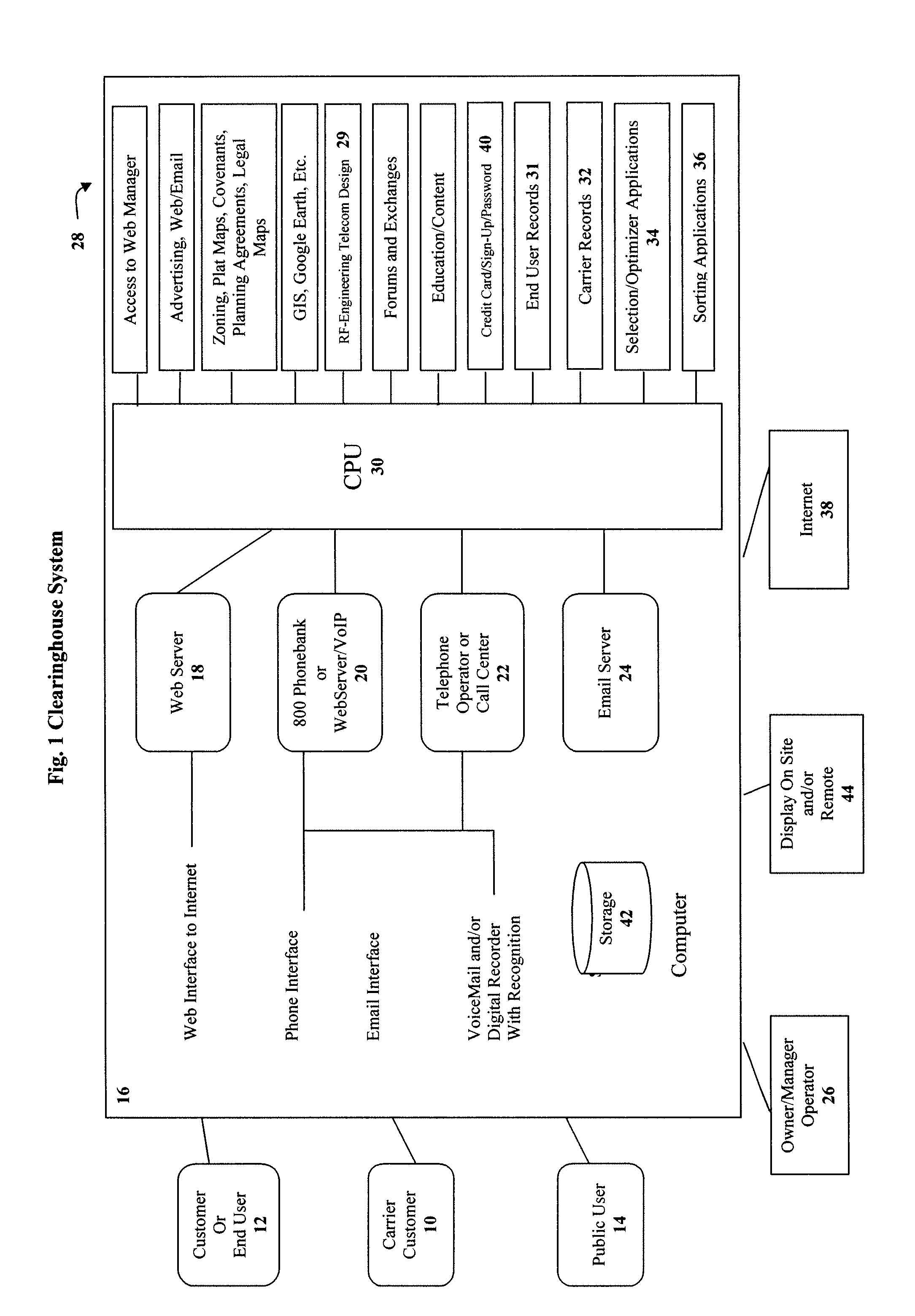

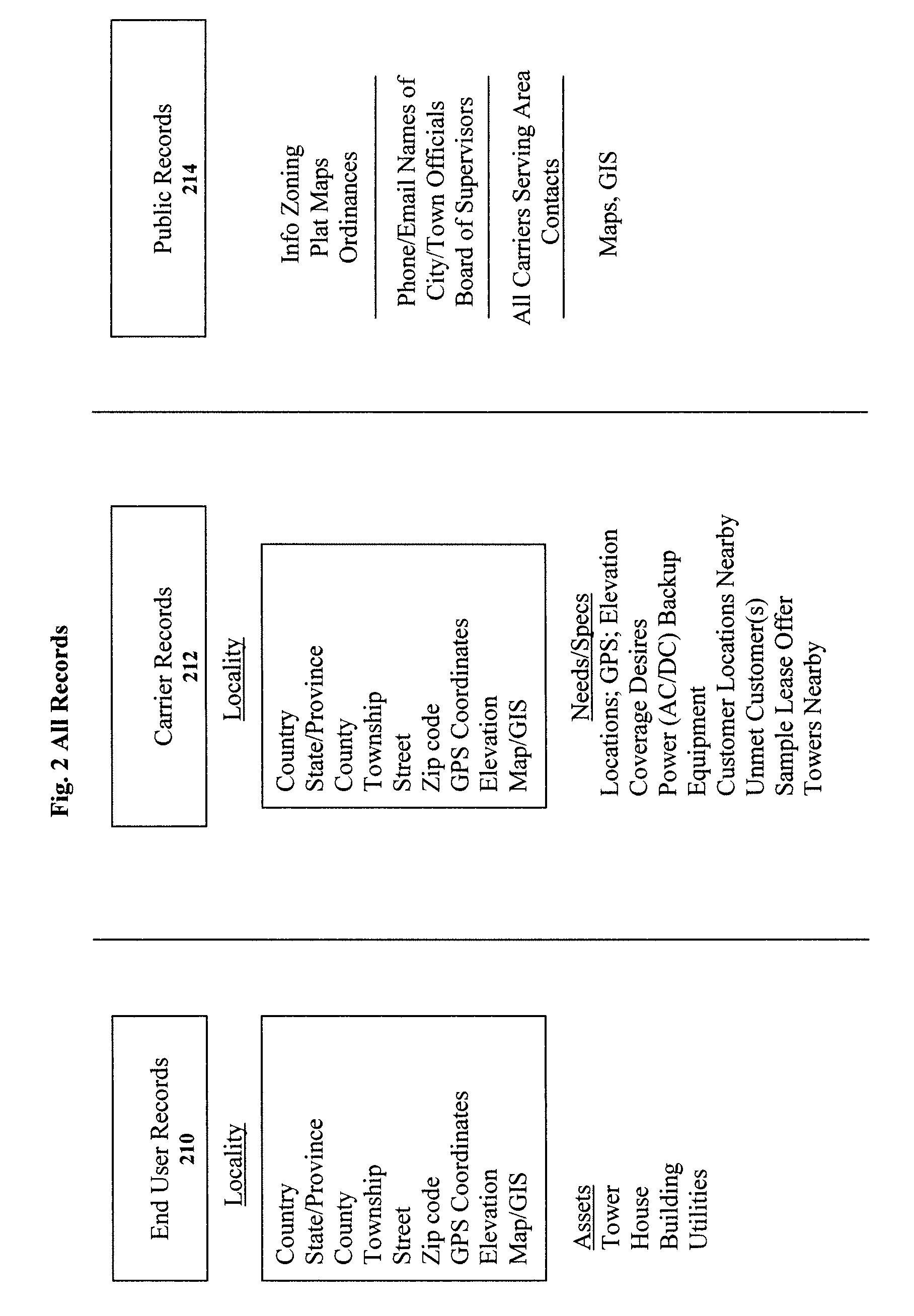

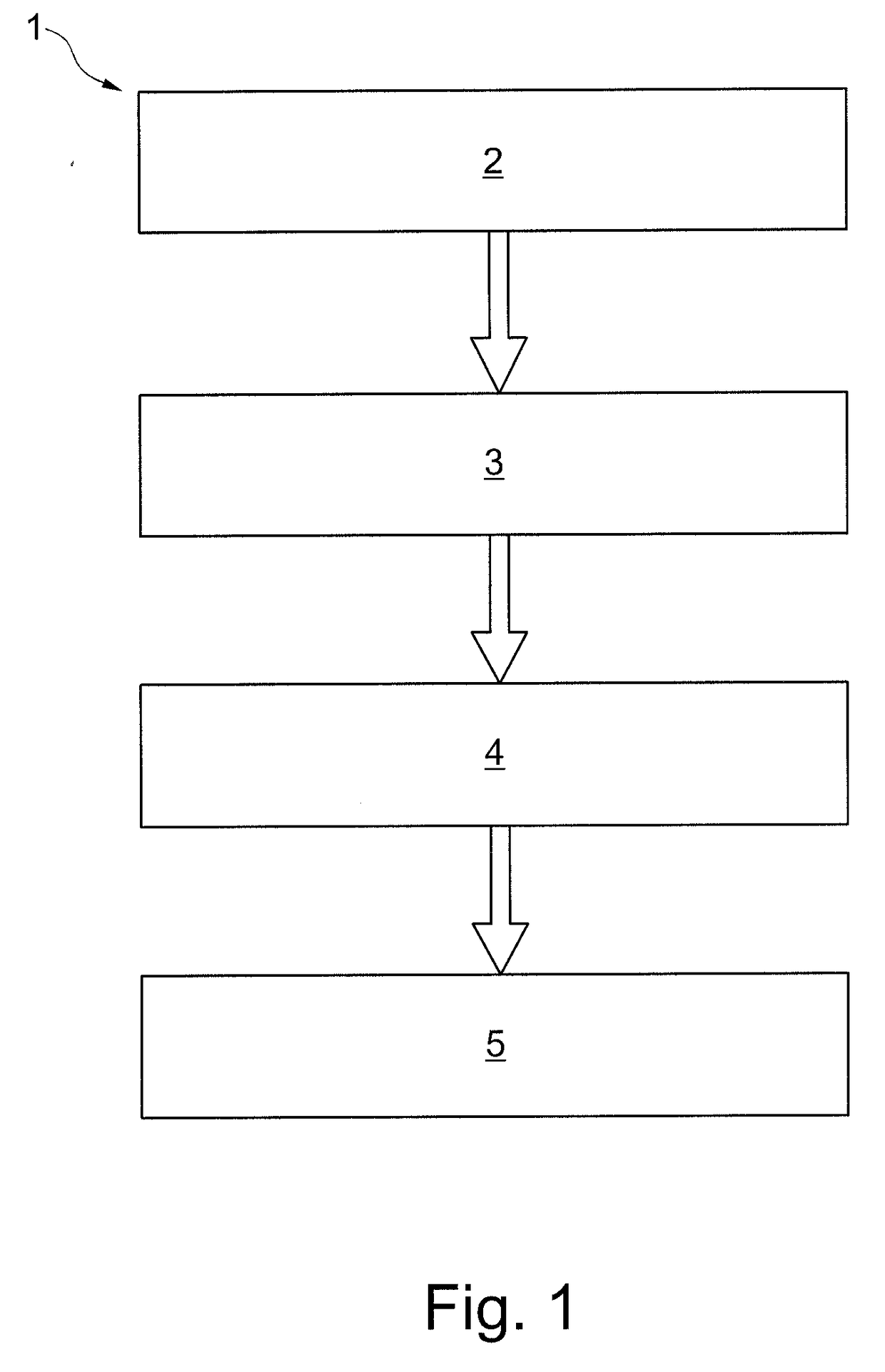

A computerized system, method and process allows telecommunications carriers to find, evaluate and select locations for equipment through direct access to end users, while providing citizens the opportunity to offer the use of their dwelling or other assets to carriers. The system and method further provides a computerized mechanism for (a) creating an inventory and marketplace for available properties for use in telecommunications networks, (b) providing quality and / or performance monitoring and control for wireless communication systems based on data in the clearinghouse, and (c) providing localized content over wireless networks using the clearinghouse.

Owner:RAPPAPORT THEODORE S

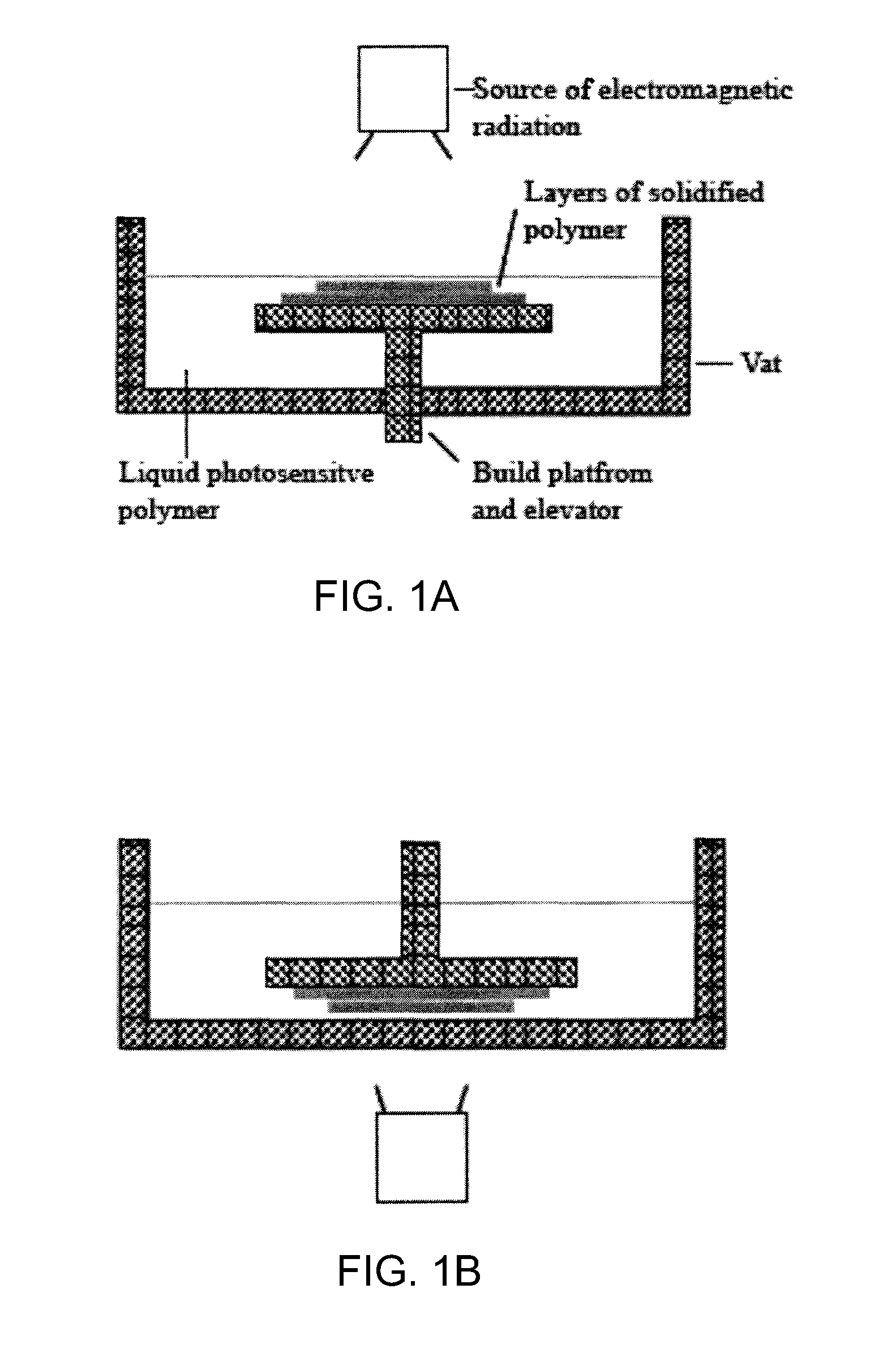

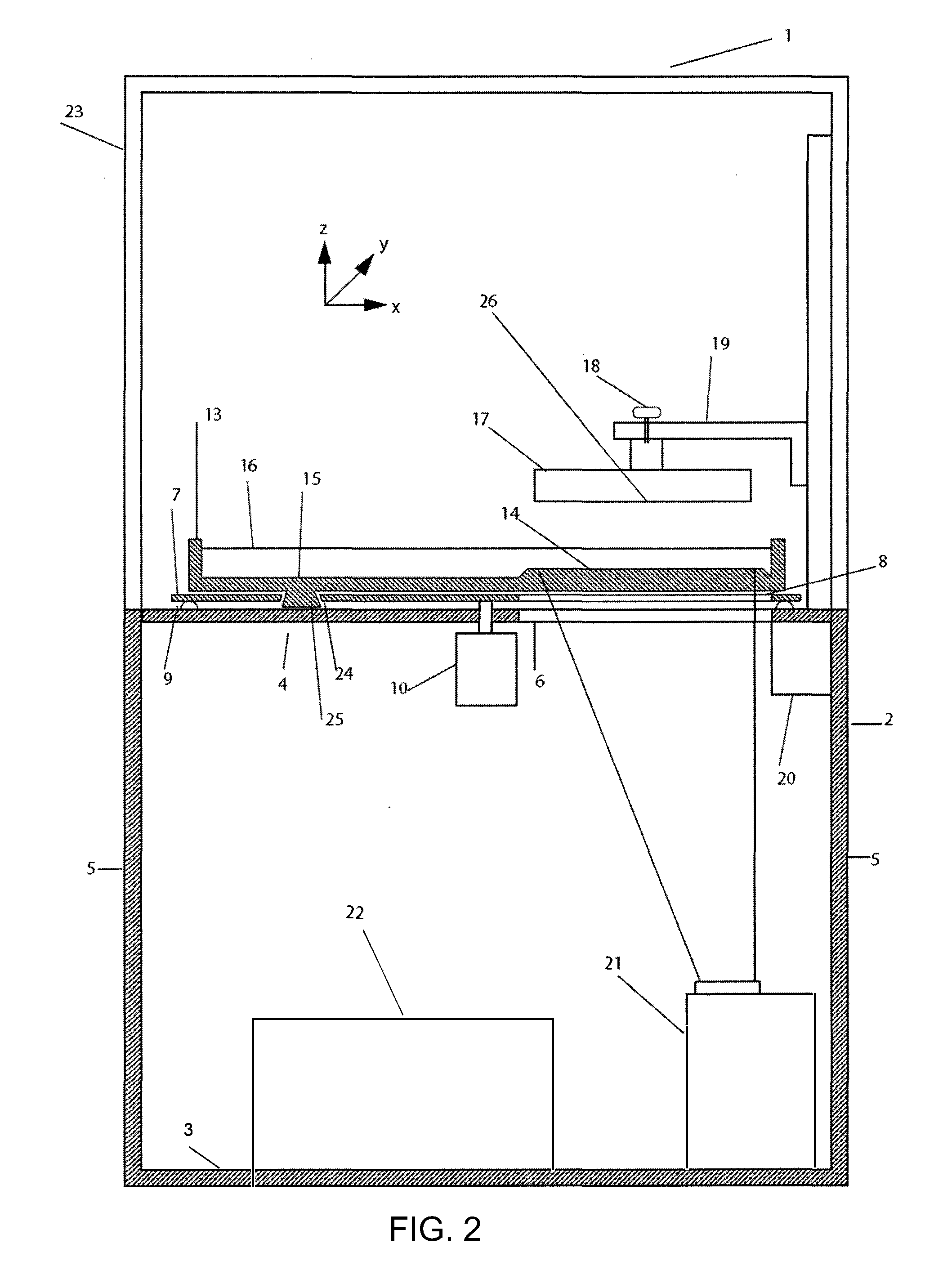

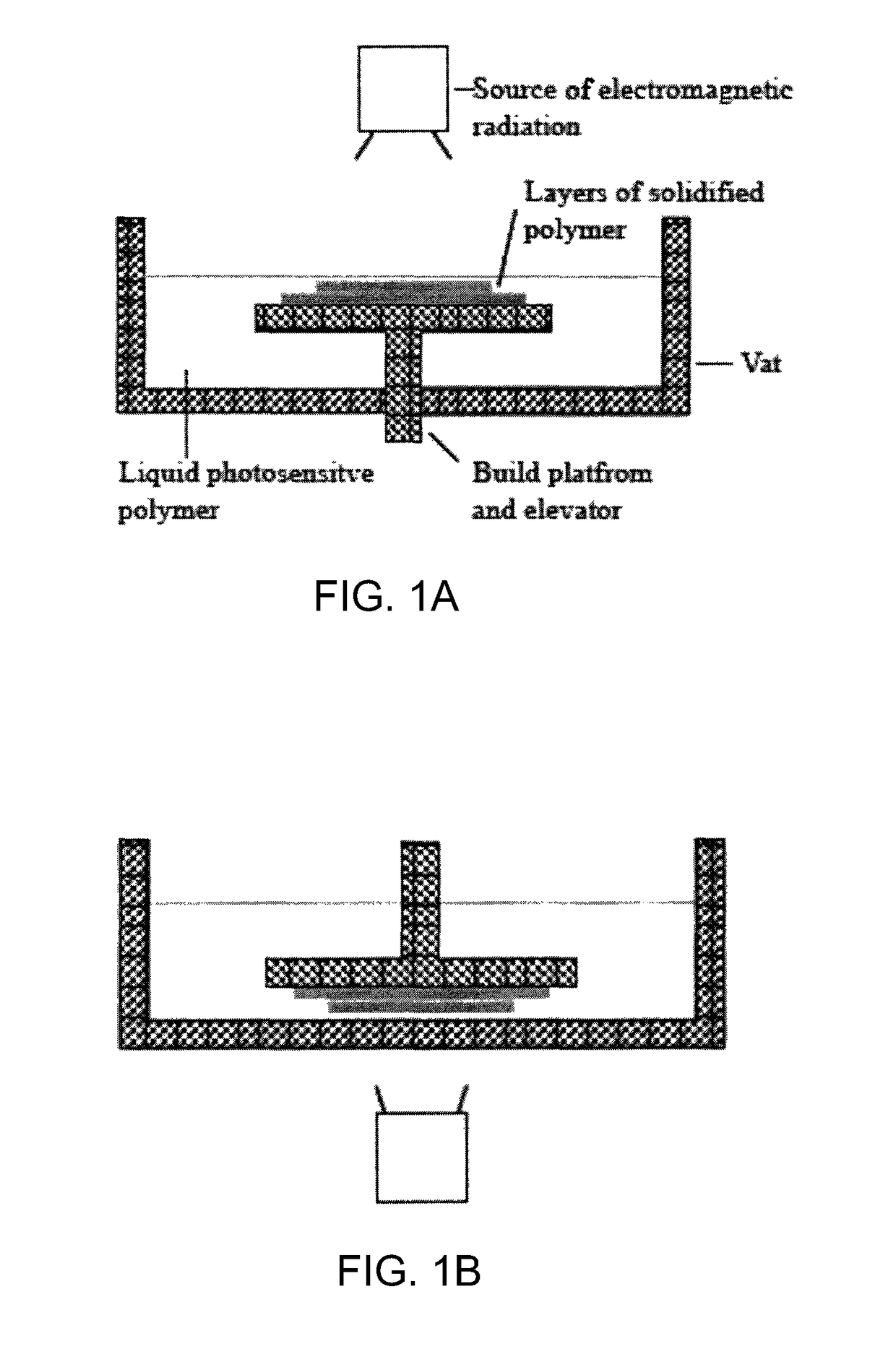

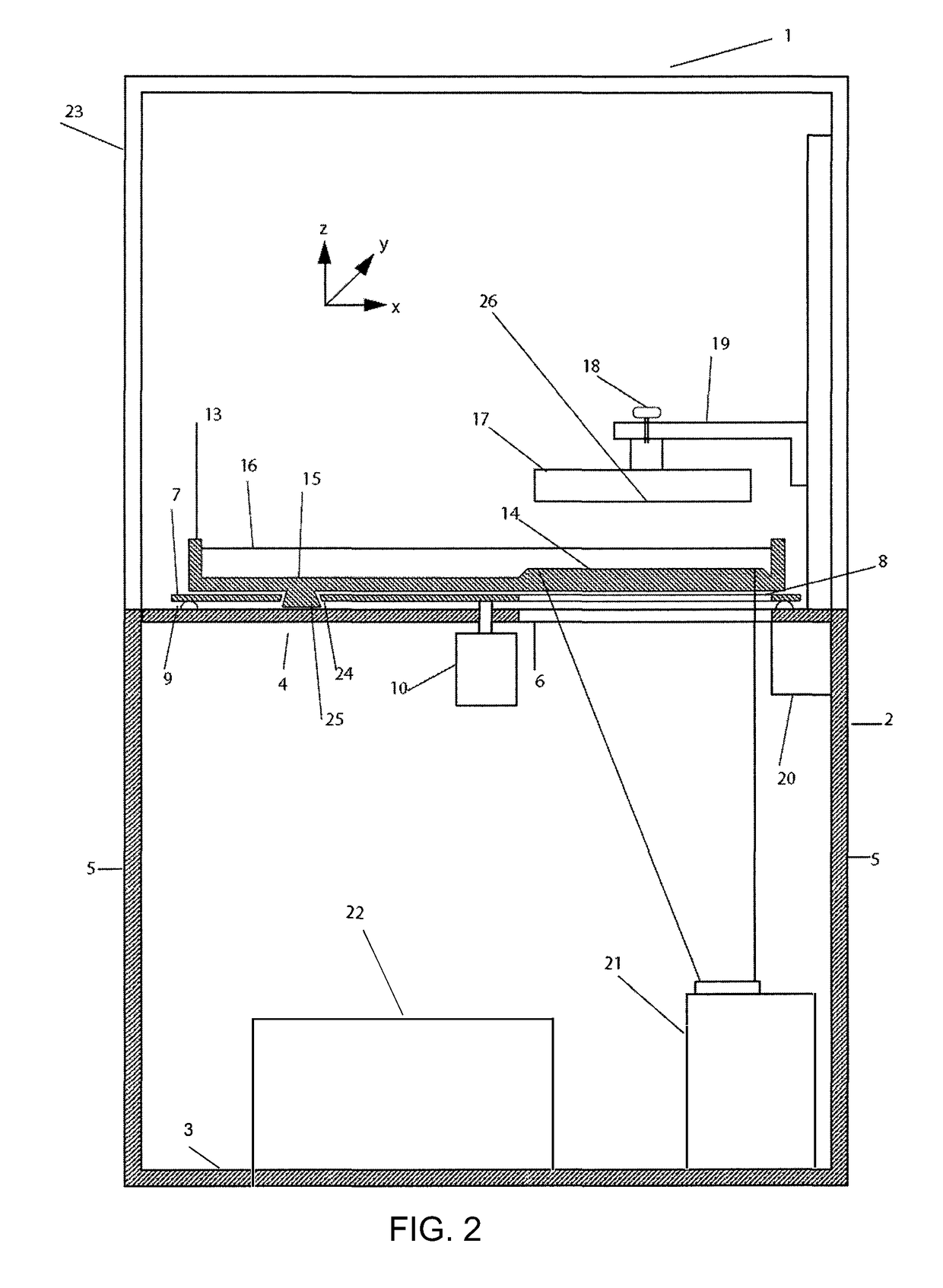

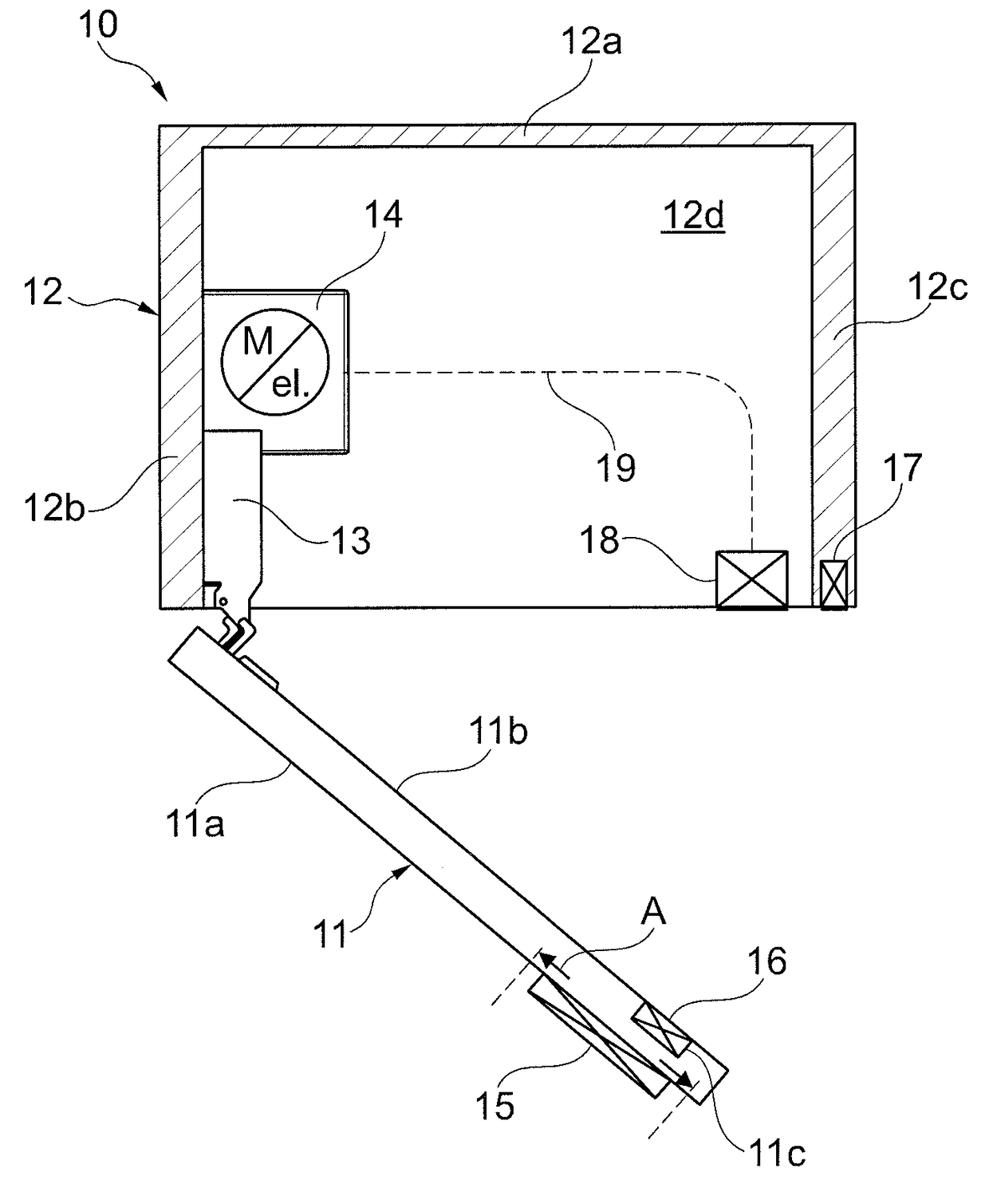

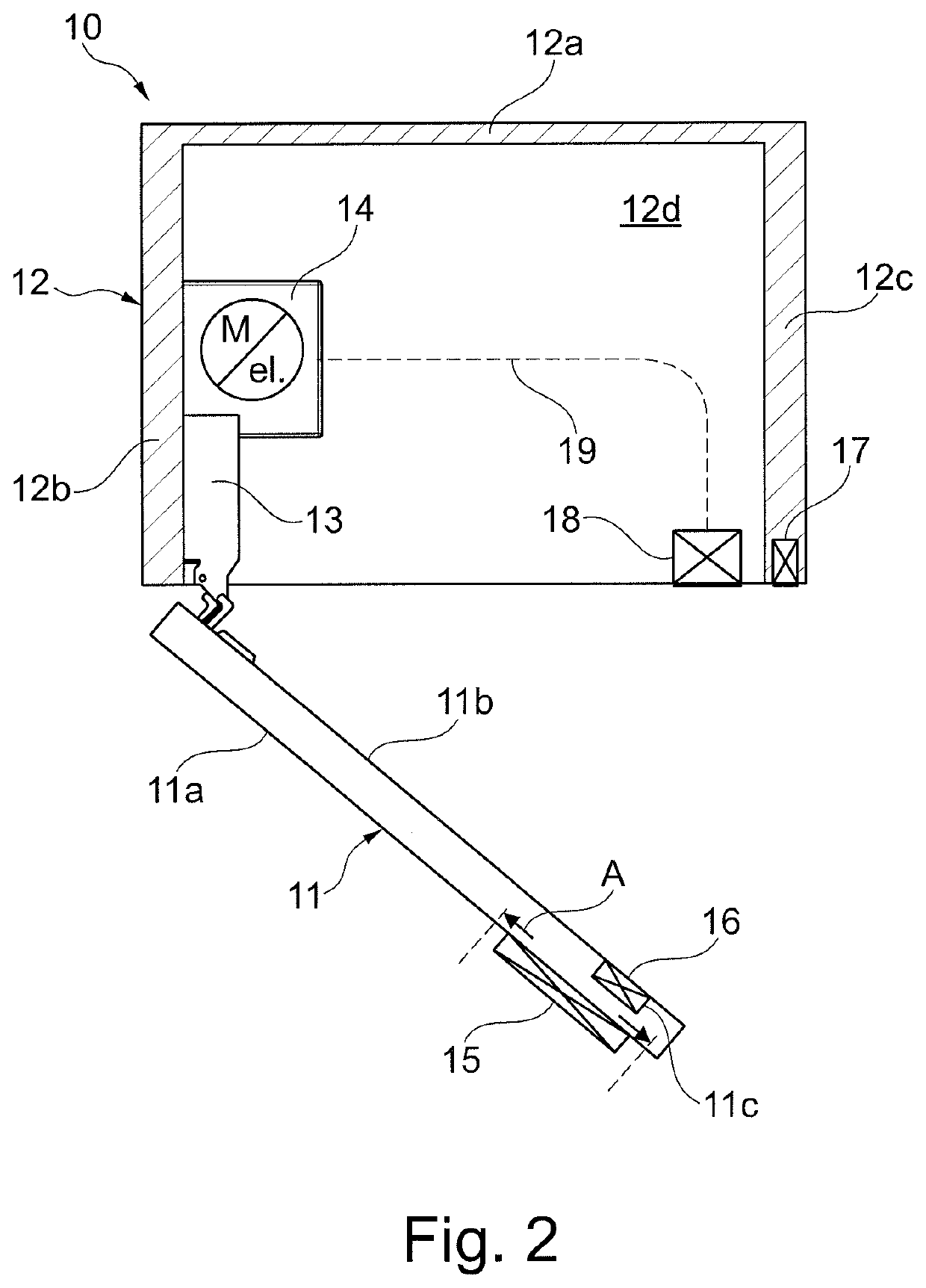

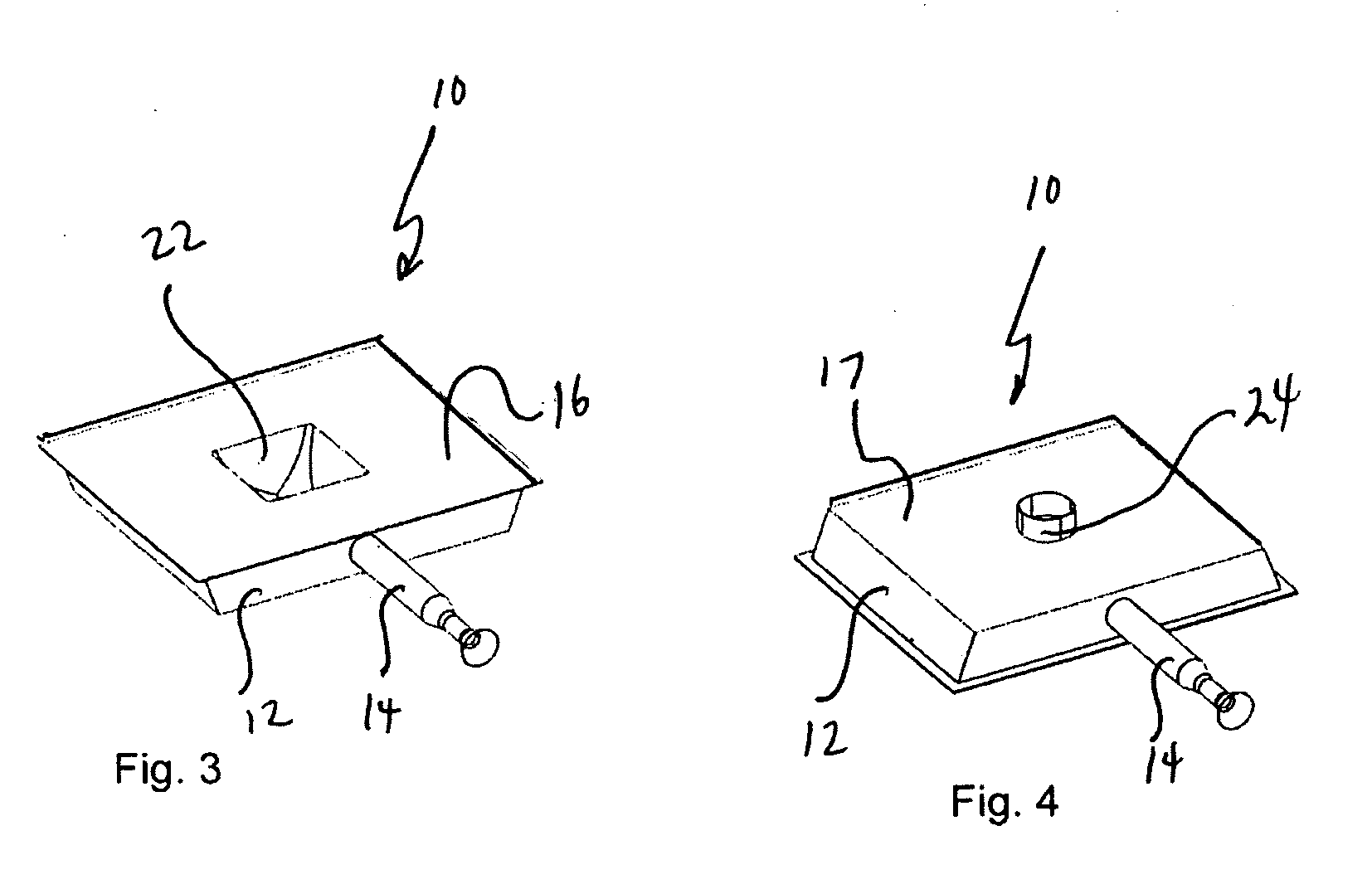

Apparatus for fabrication of three dimensional objects

ActiveUS20140339741A1Reduce power outputIncrease exposure timeManufacturing driving meansManufacturing enclosuresPhotosensitive polymerEngineering

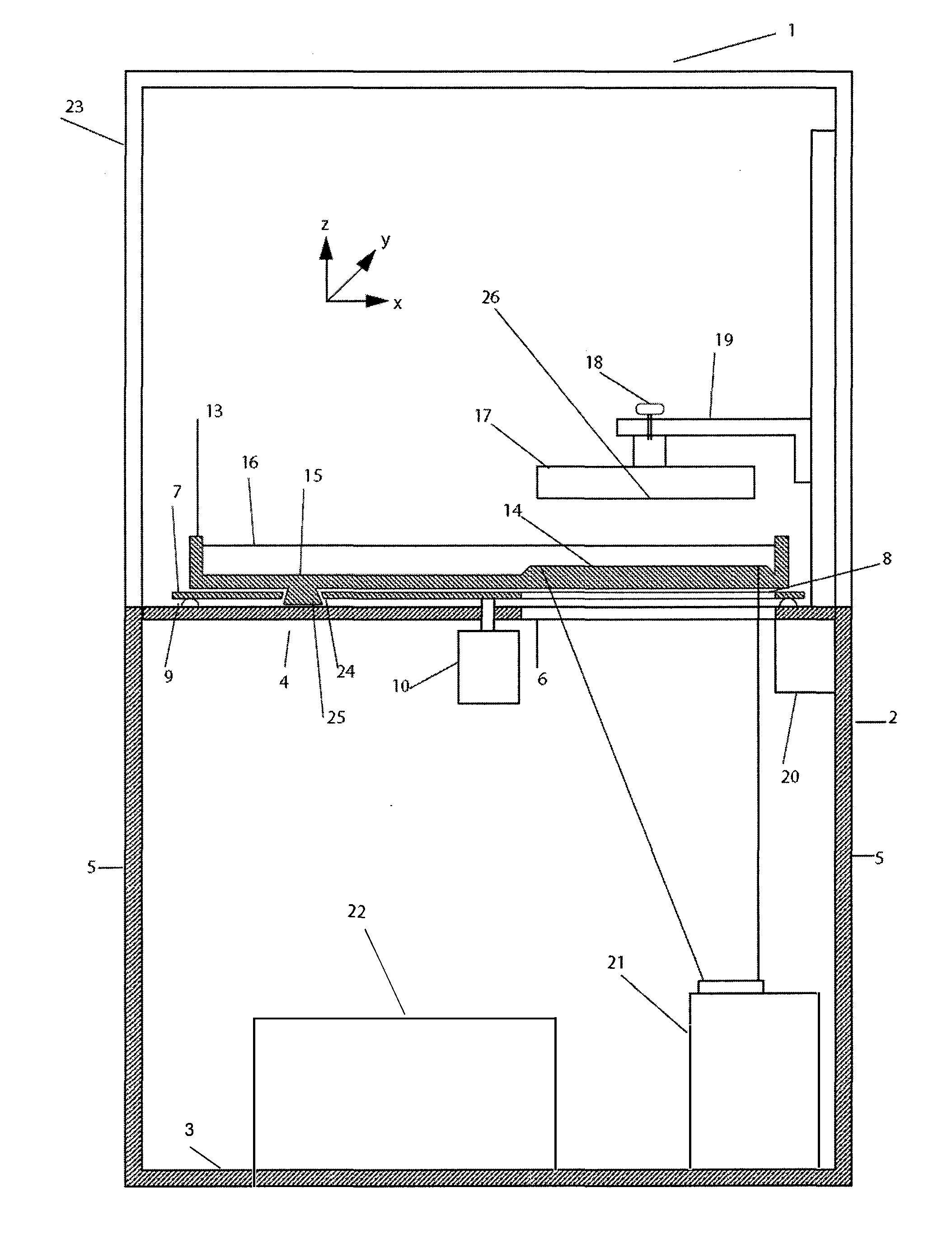

An apparatus for bottom-up fabrication of three dimensional objects, the apparatus comprising: a vat for a photosensitive polymer, the floor of the vat including a working surface arranged such that, in use, light incident on the working surface interacts with the photosensitive polymer at the working surface to fabricate a portion of the three dimensional object; a build platform capable of being inserted into the vat, the build platform having a planar surface; an elevator mechanism capable of adjusting the separation between the working surface of the vat and the planar surface of the build platform; and a rotation mechanism capable of varying the relative rotational position of the vat relative to the build platform, the relative rotation being about an axis which is normal to the working surface of the vat.

Owner:HOLO INC

Clearinghouse System and Method for Determining Availability of Carrier-Based Services and Enhancing the Quality, Operation and Accessibility of Carrier-Based Networks

ActiveUS20100250269A1Broaden their knowledgeLow costError detection/correctionDigital data processing detailsCommunications systemTelecommunications network

A computerized system, method and process allows telecommunications carriers to find, evaluate and select locations for equipment through direct access to end users, while providing citizens the opportunity to offer the use of their dwelling or other assets to carriers. The system and method further provides a computerized mechanism for (a) creating an inventory and marketplace for available properties for use in telecommunications networks, (b) providing quality and / or performance monitoring and control for wireless communication systems based on data in the clearinghouse, and (c) providing localized content over wireless networks using the clearinghouse.

Owner:RAPPAPORT THEODORE S

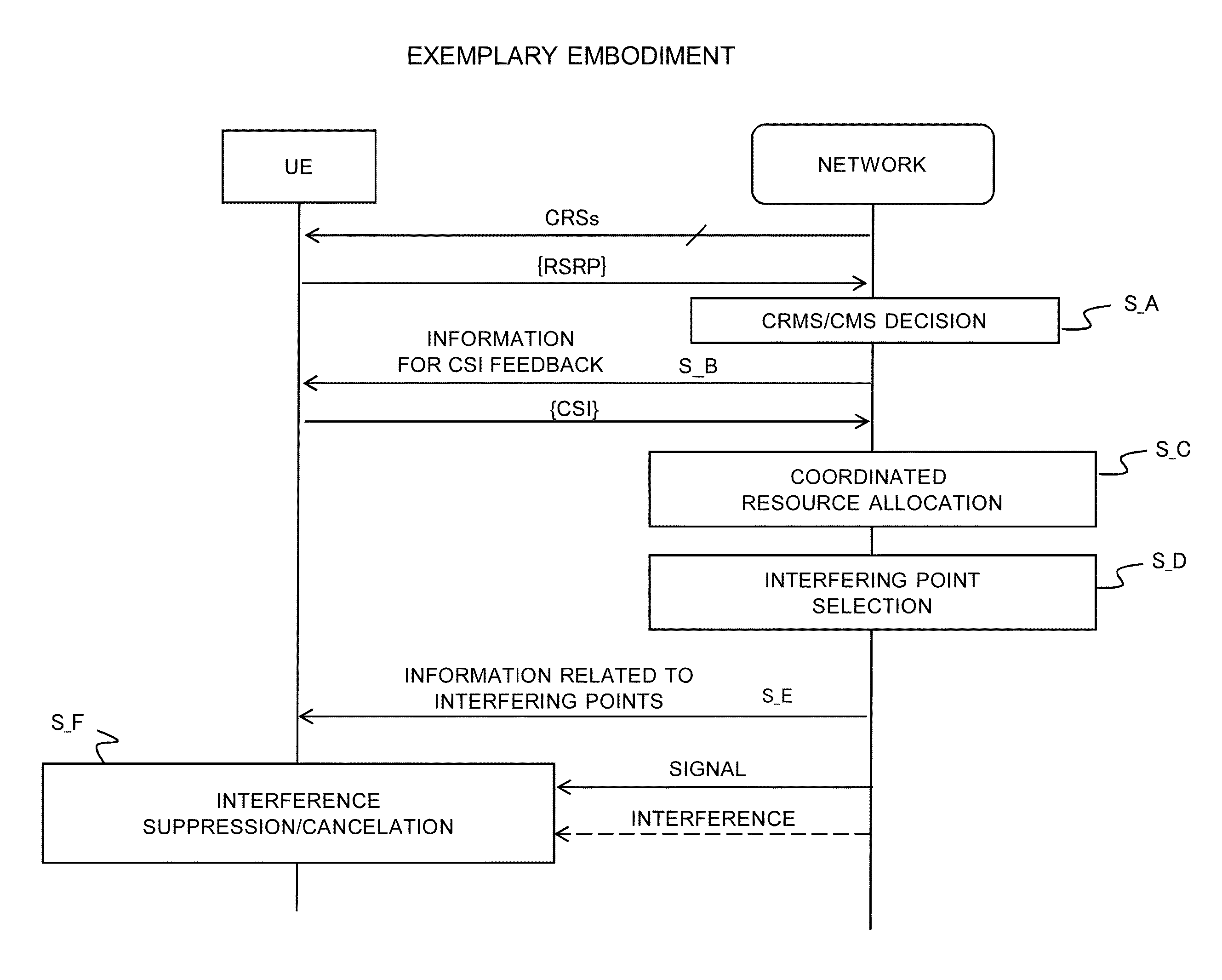

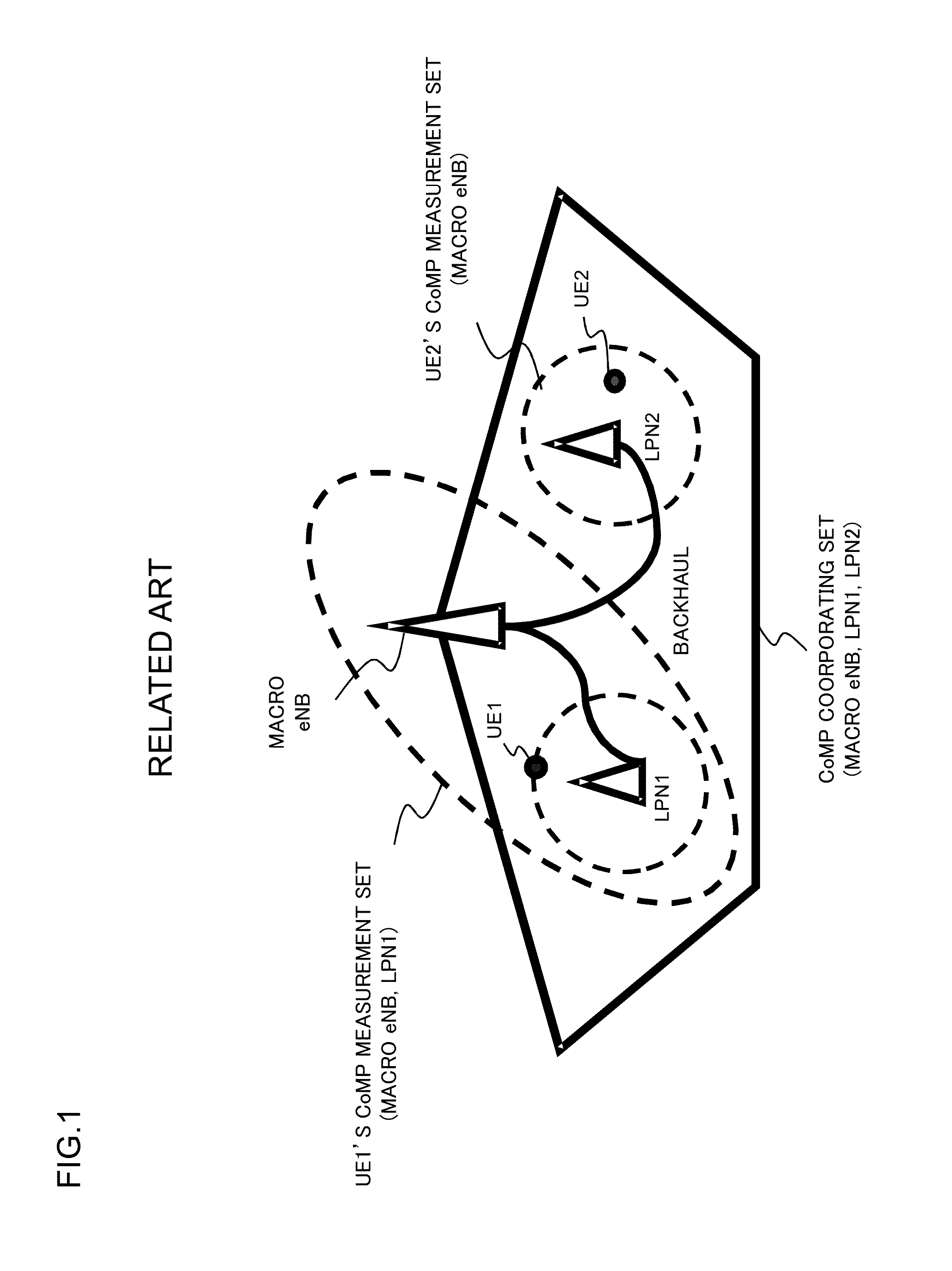

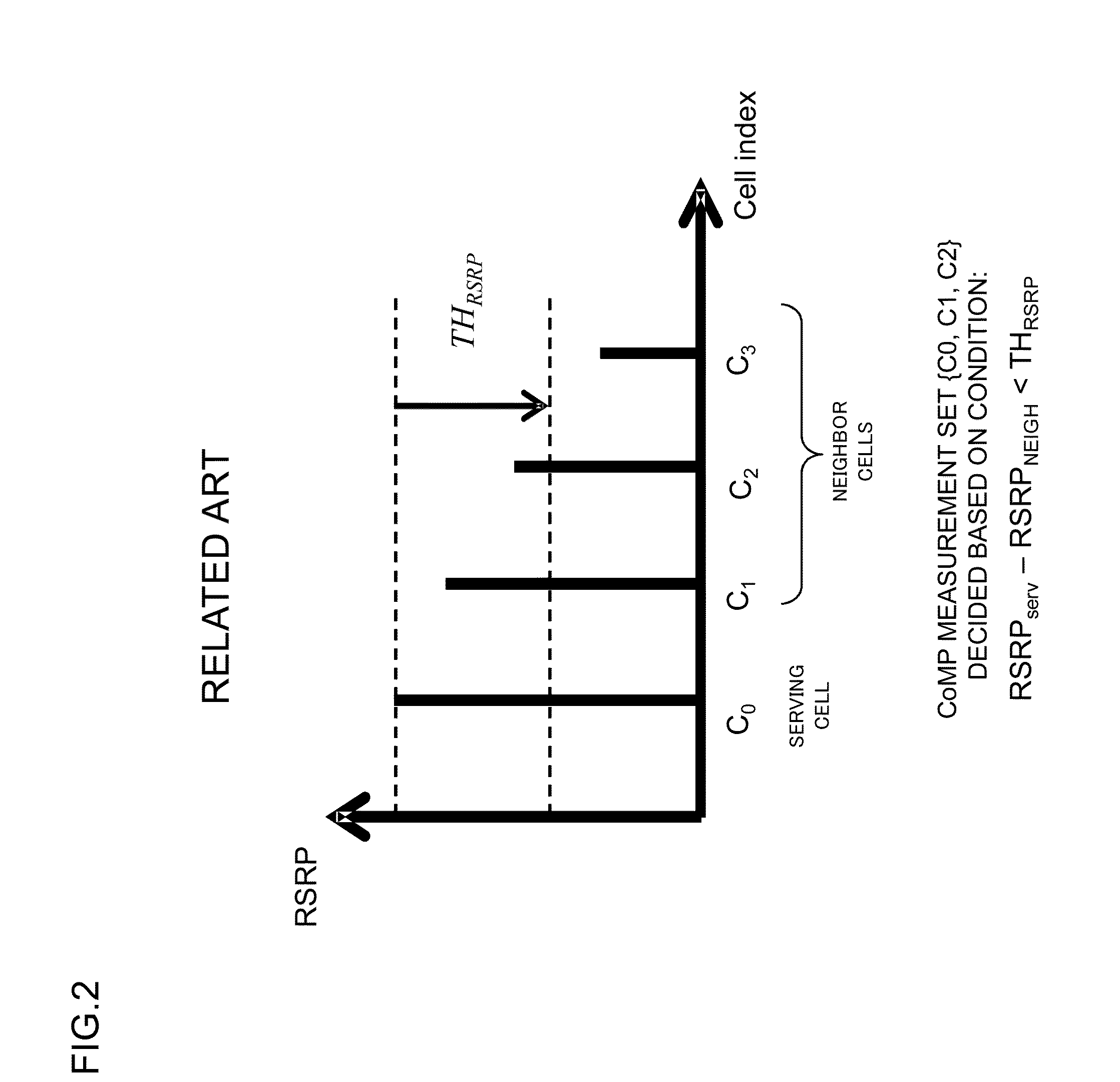

Method and system for network-assisted interference suppression/cancelation

InactiveUS20150382371A1Effective interference suppression/cancelationEquipment efficientSite diversitySpatial transmit diversityTelecommunicationsMultiple point

A system which can achieve effective interference suppression / cancelation in downlink coordinated multi-point (CpMP) transmission is provided. The system has a network including multiple points which are capable of communicating with a user equipment, wherein the network sends information related to an interfering point to the user equipment for interference suppression or cancelation at the user equipment, wherein the interfering point is a candidate for a coordinated multi-point measurement set of the user equipment but not selected for any coordinated multi-point scheme.

Owner:NEC CORP

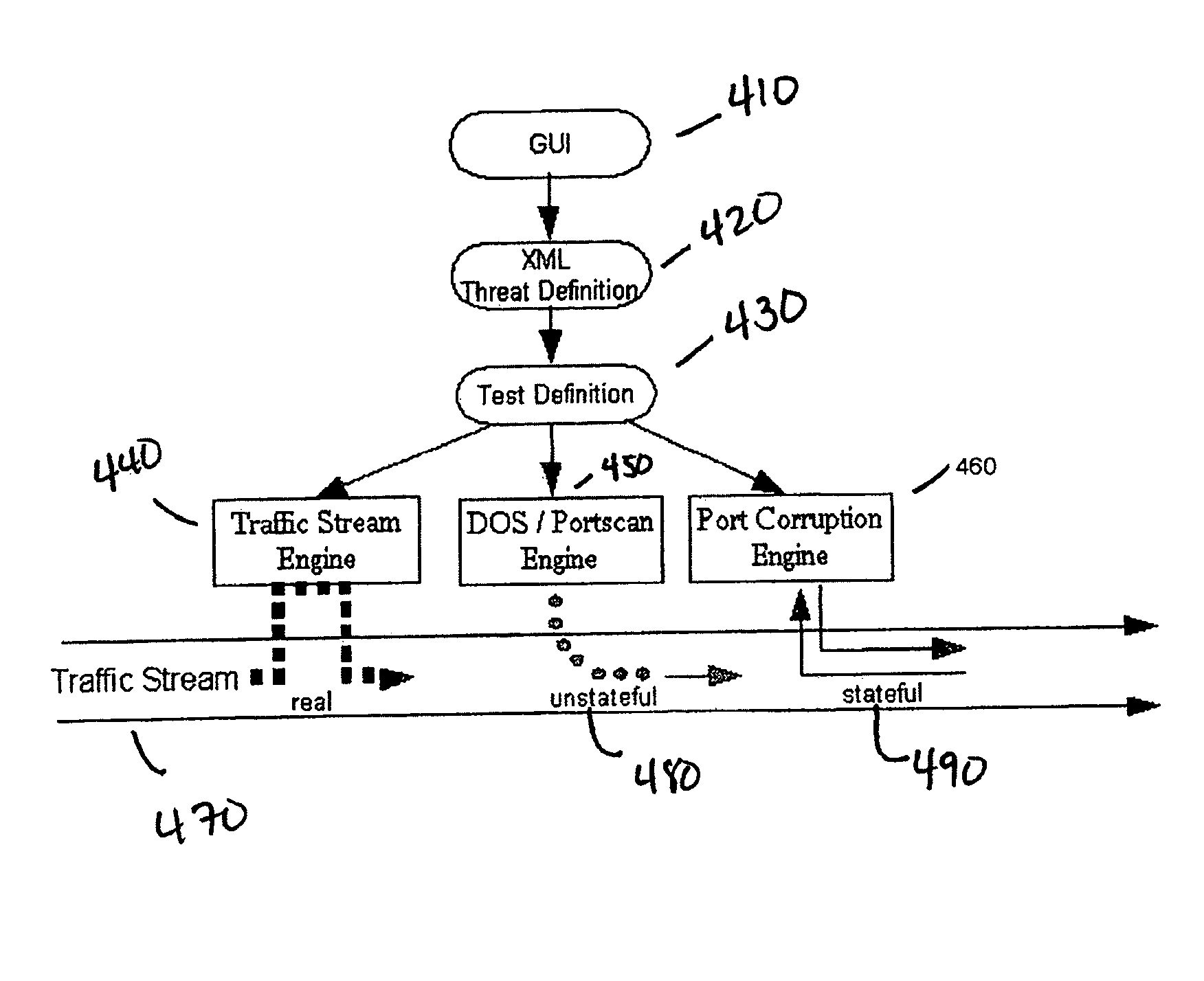

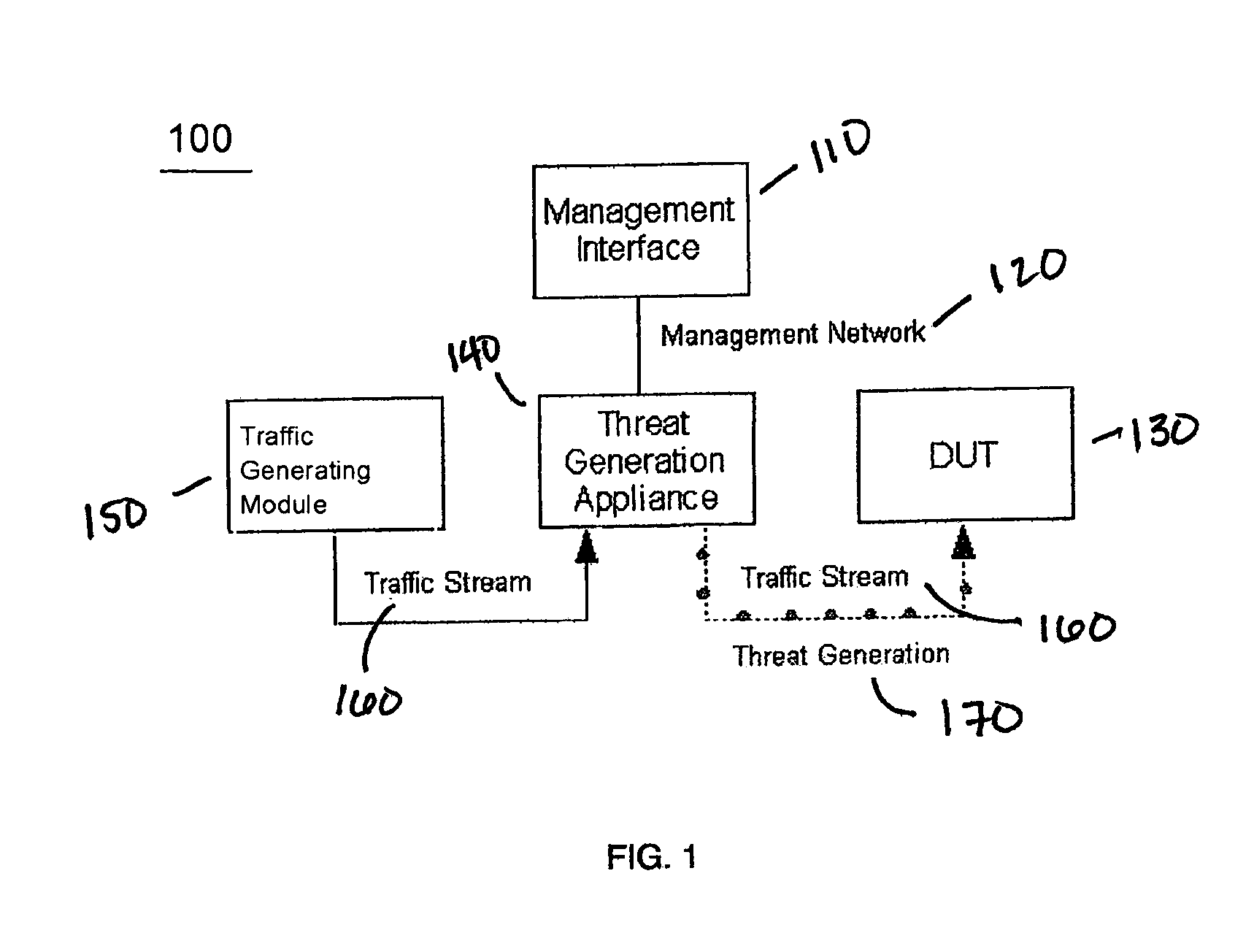

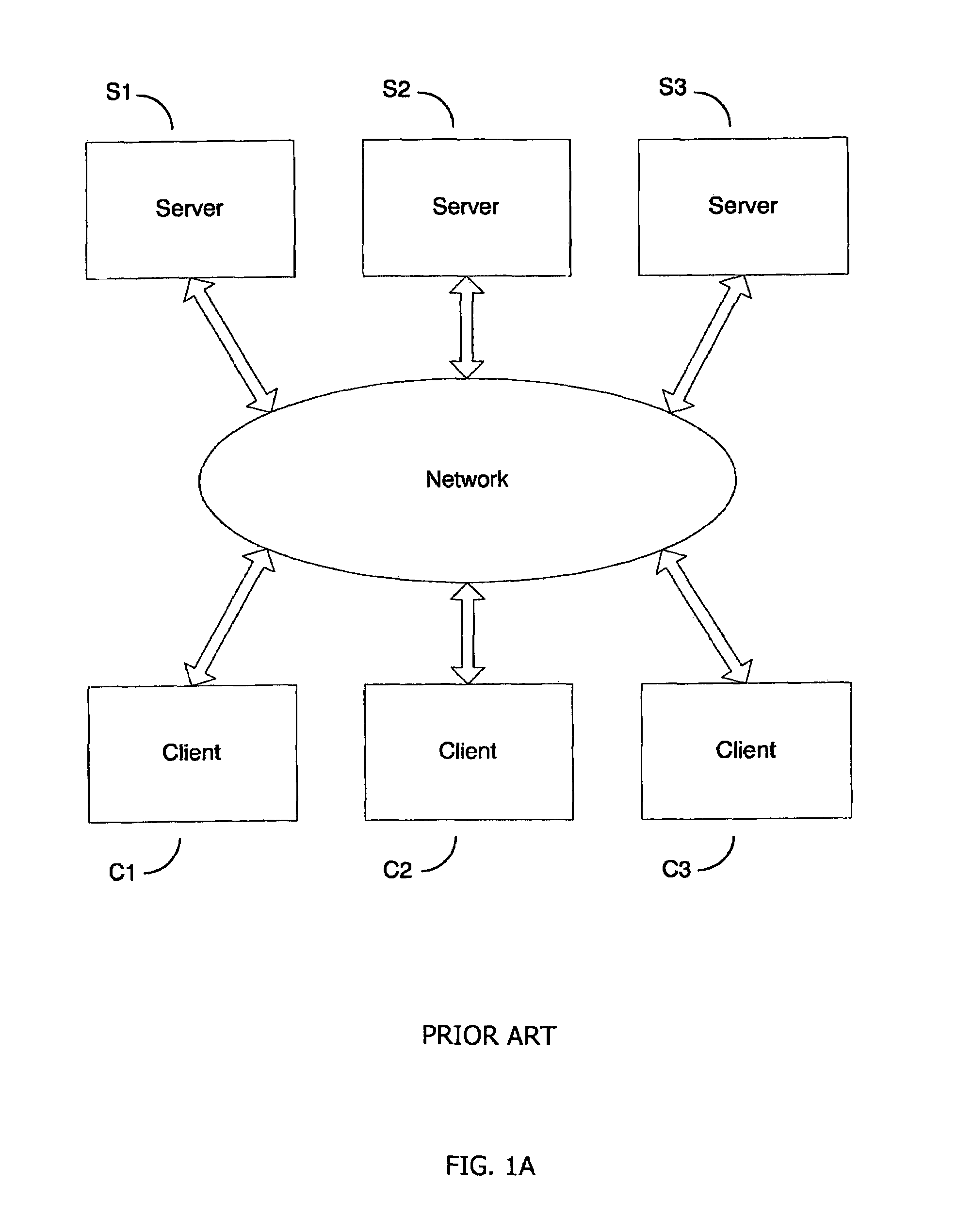

Network testing methods and systems

ActiveUS7620989B1Quickly and efficiently distributedEfficient testingMemory loss protectionError detection/correctionWeb threatTraffic capacity

Network vulnerability testing methods, systems, devices, appliances and software products generate stateful and stateless network representative of network threats. The traffic is applied to a network or device under test, thereby to test the vulnerability of the network or device to threats. A graphical user interface, which does not require a programming or scripting language can be used to generate an intermediate descriptive format that can in turn be used to generate stateful or stateless threat signatures. By using the intermediate descriptive form, threats can be generated under the control of the graphical user interface and in accordance with stored threat signatures, without the need for a programming or scripting language.

Owner:SPIRENT COMM

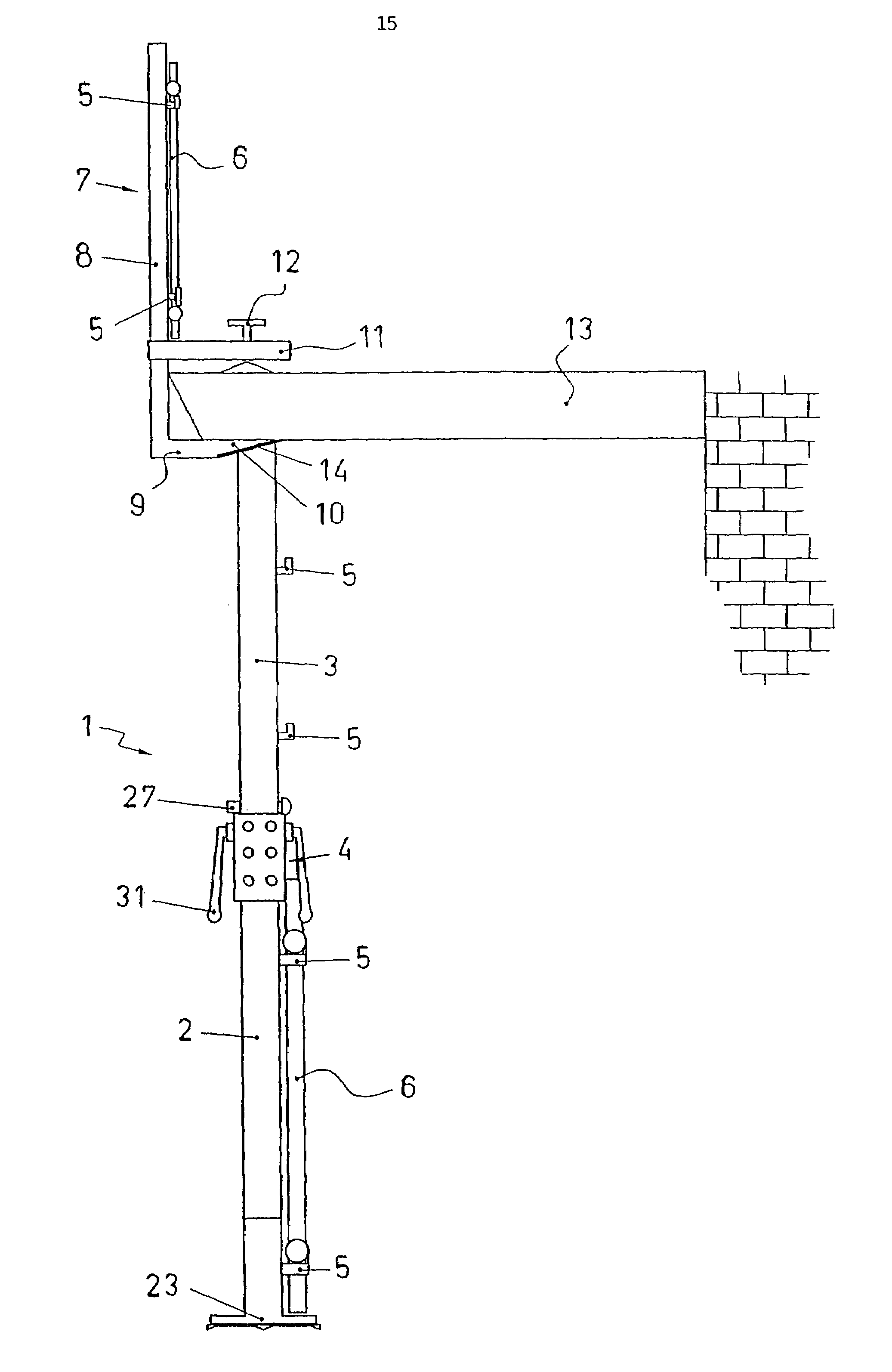

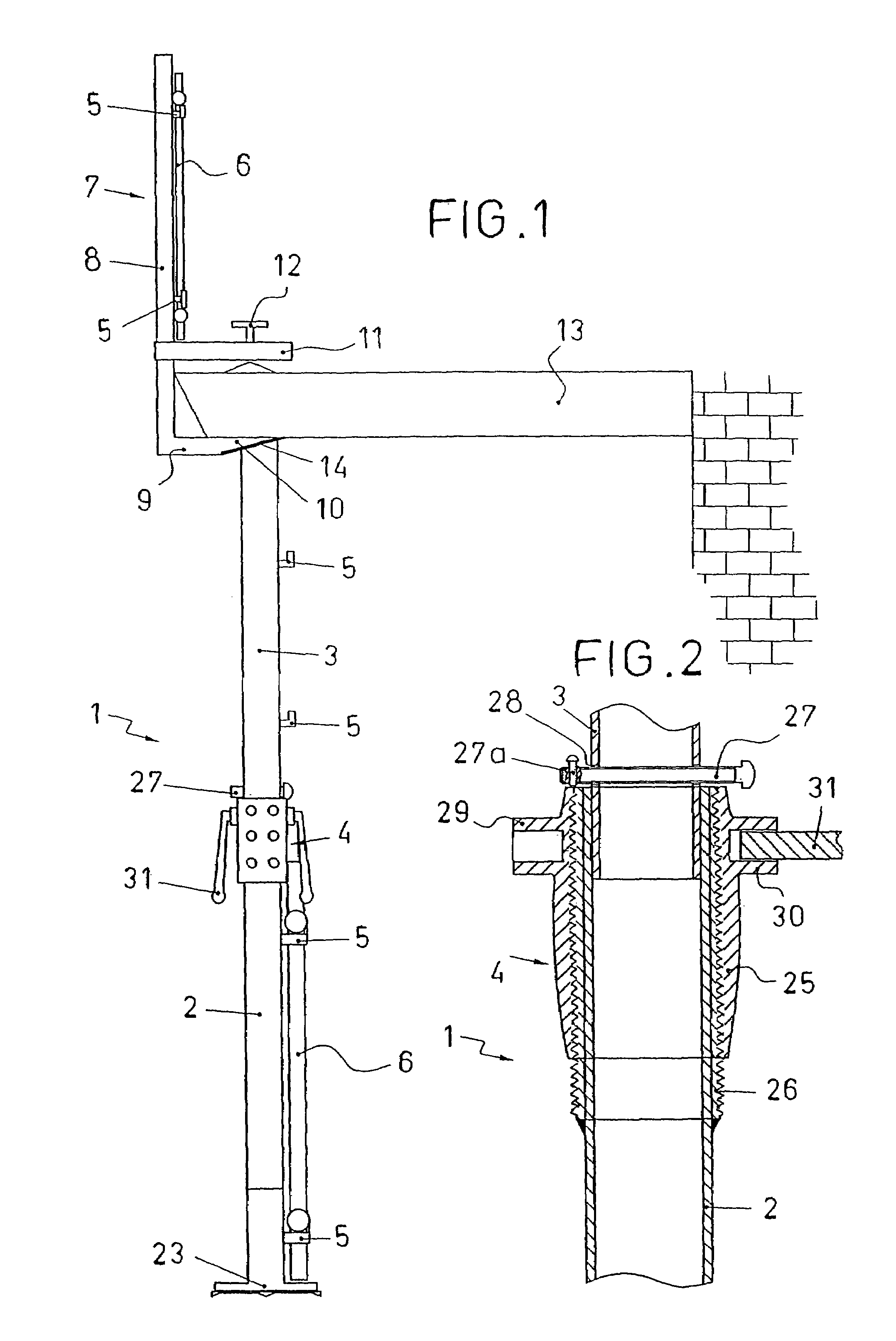

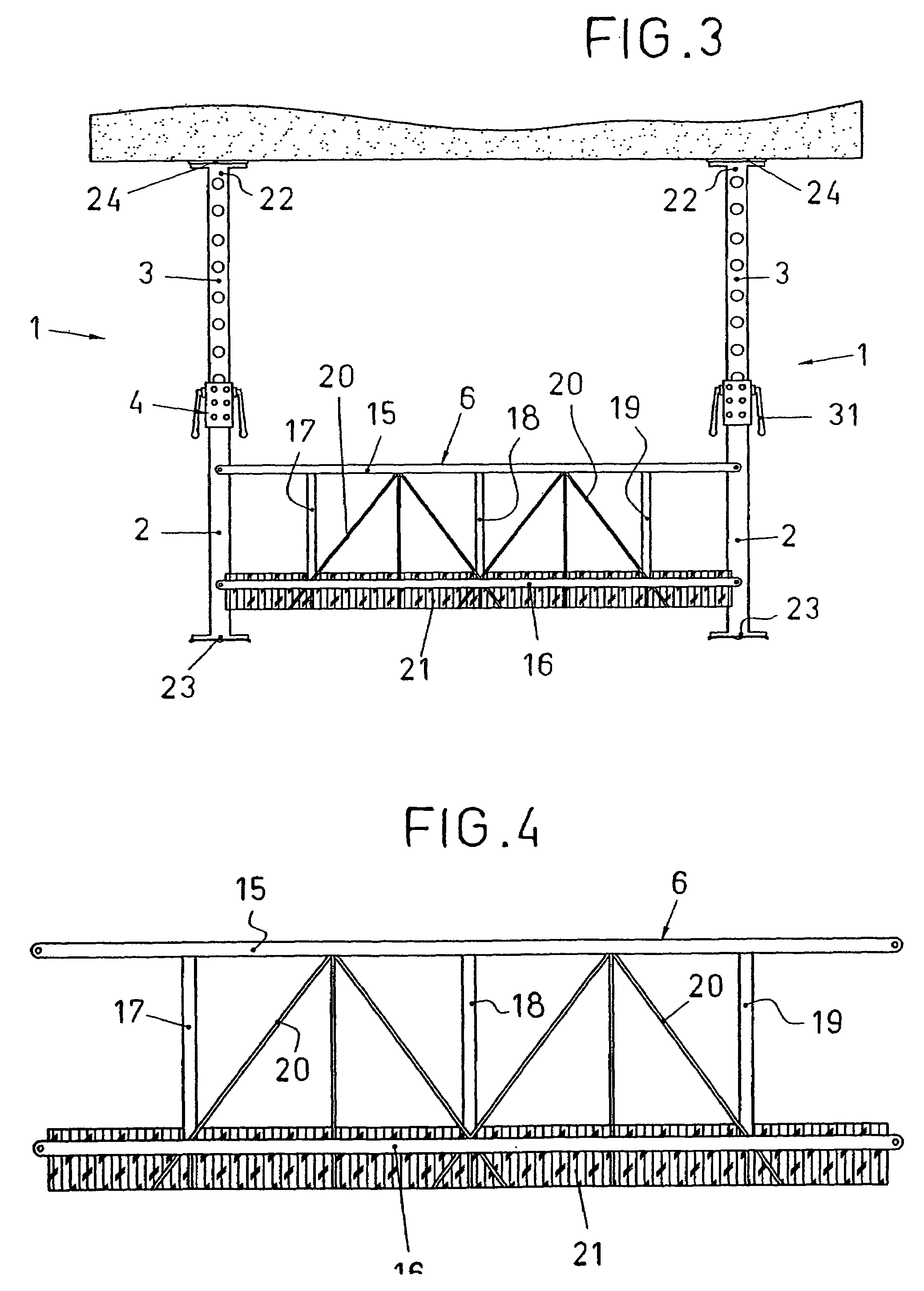

Safety equipment for building sites

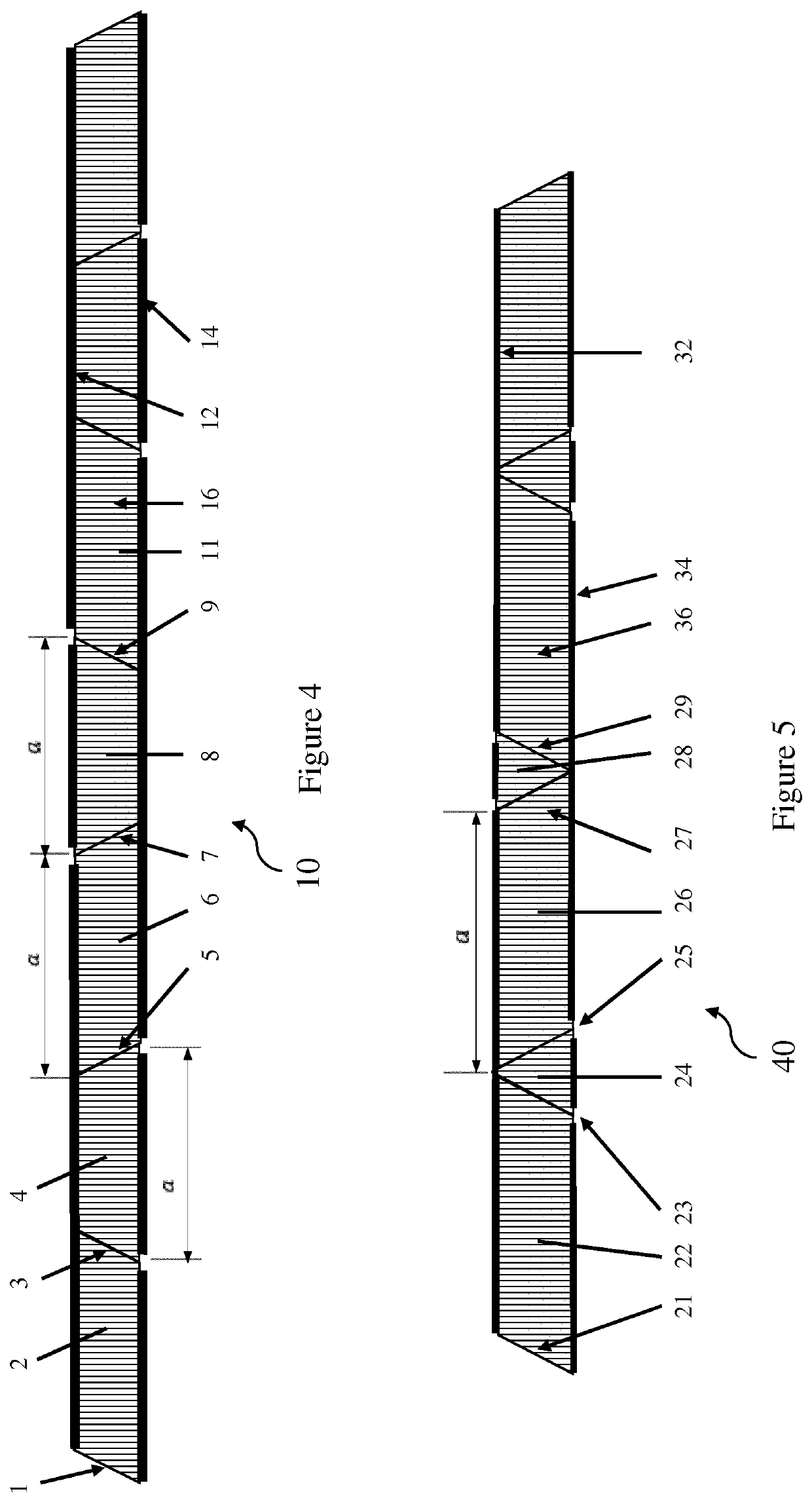

InactiveUS7273200B2Simple equipmentEasy to assembleFencingLifting devicesArchitectural engineeringCornice

The invention relates to a construction safety assembly. The inventive assembly comprises: safety posts with non-skid ends, which are provided with means for the rapid connection of a barrier; and, optionally, an upper jack-type safety element having a lower horizontal protrusion along an inclined plane, which is used to brace the cornice or projecting element of a building and which can also comprise the aforementioned barrier connection means. The adjustable-length barrier comprises a base which covers the lower part thereof. In this way, the invention provides a dual safety assembly of very simple construction, which can be used to guarantee the collective safety of labourers performing external and internal construction work and prevent accidents.

Owner:FUNES GAVILAN TOMAS

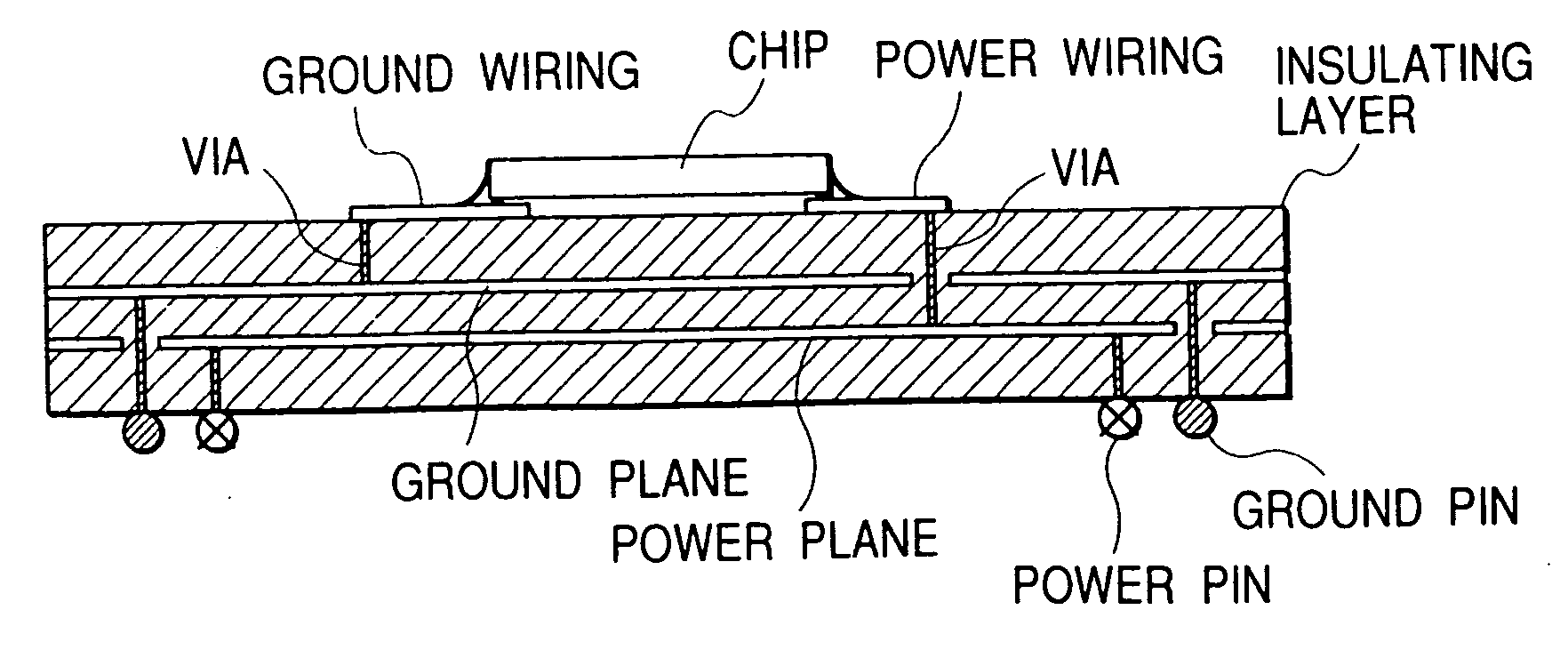

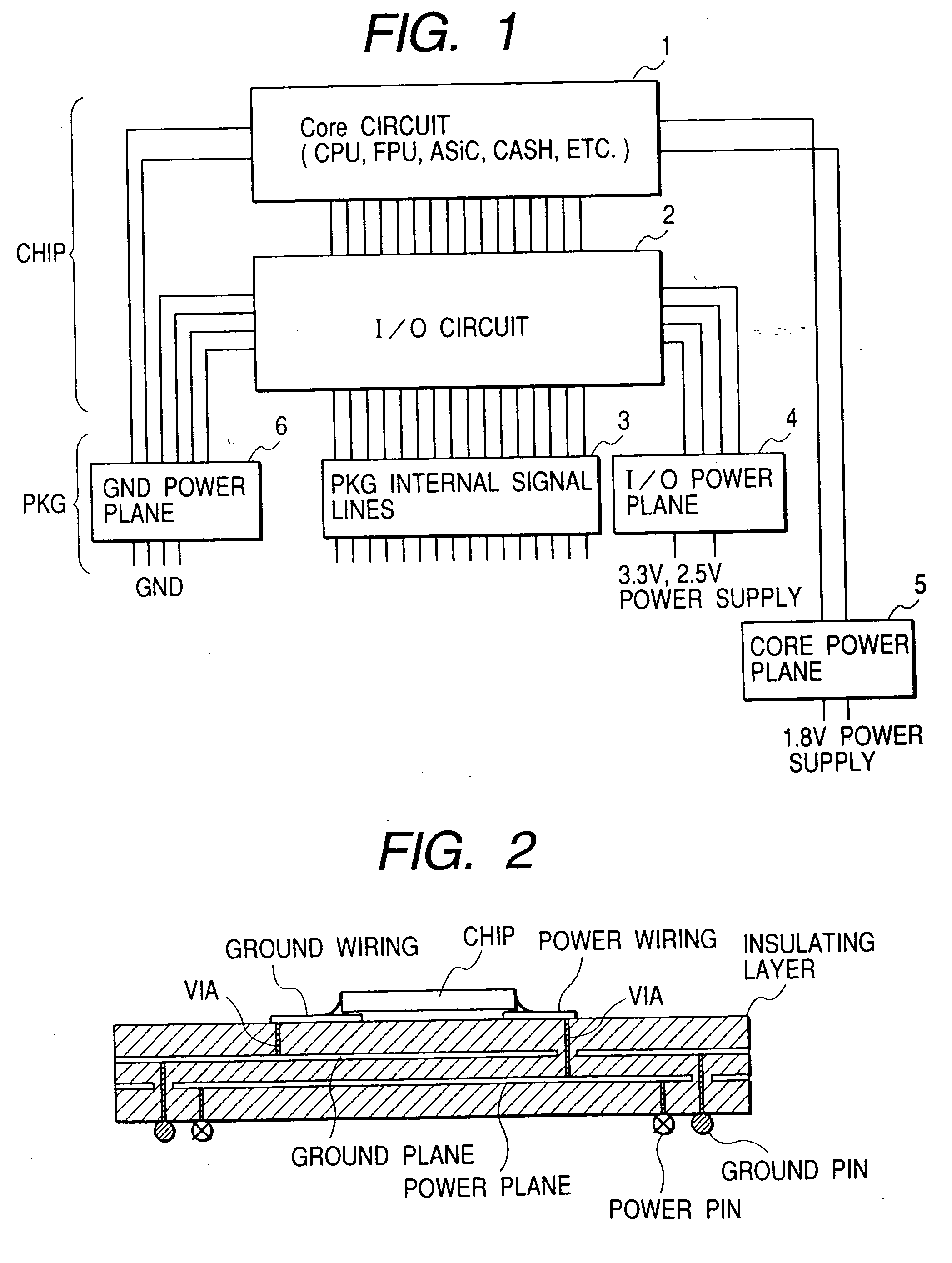

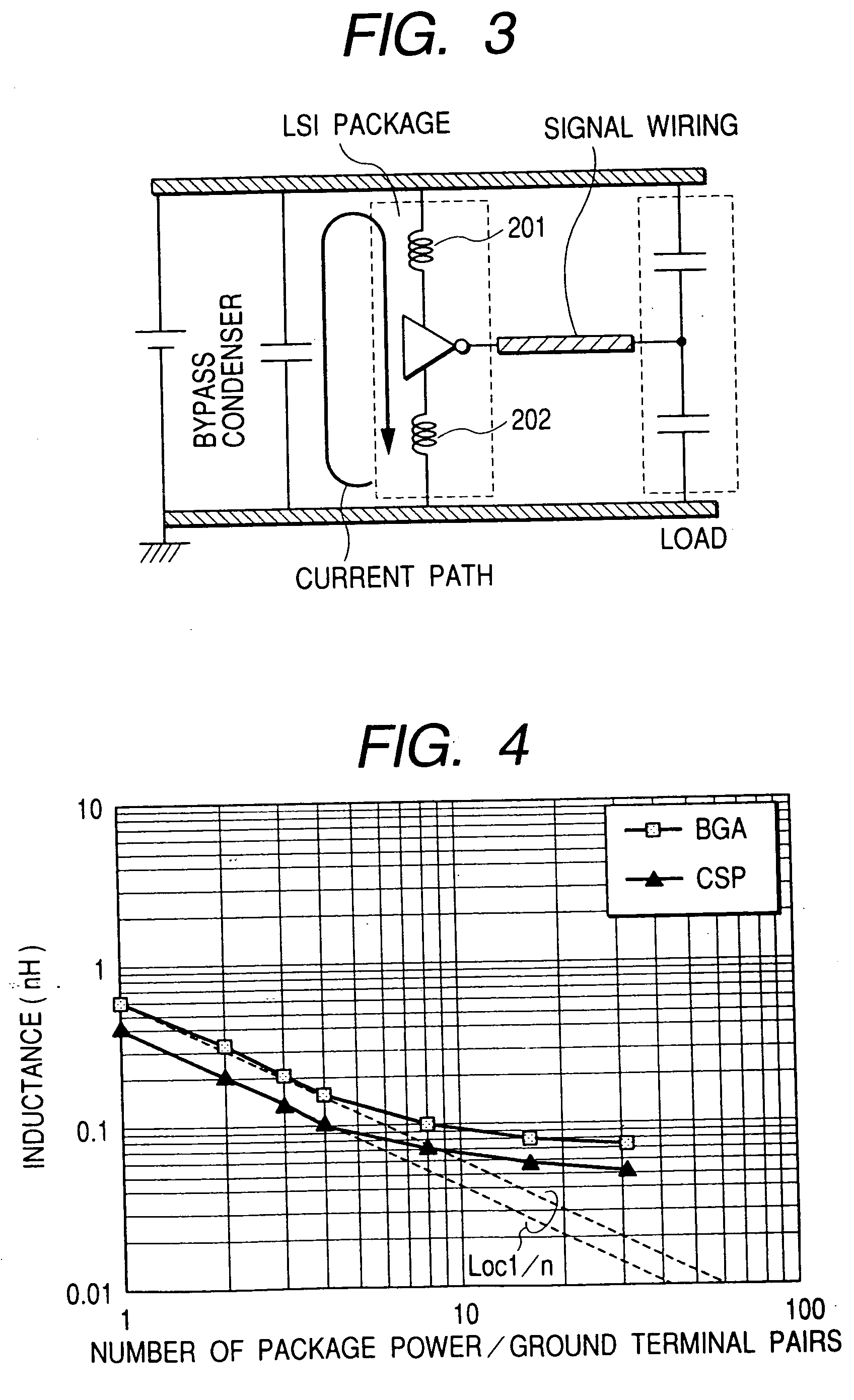

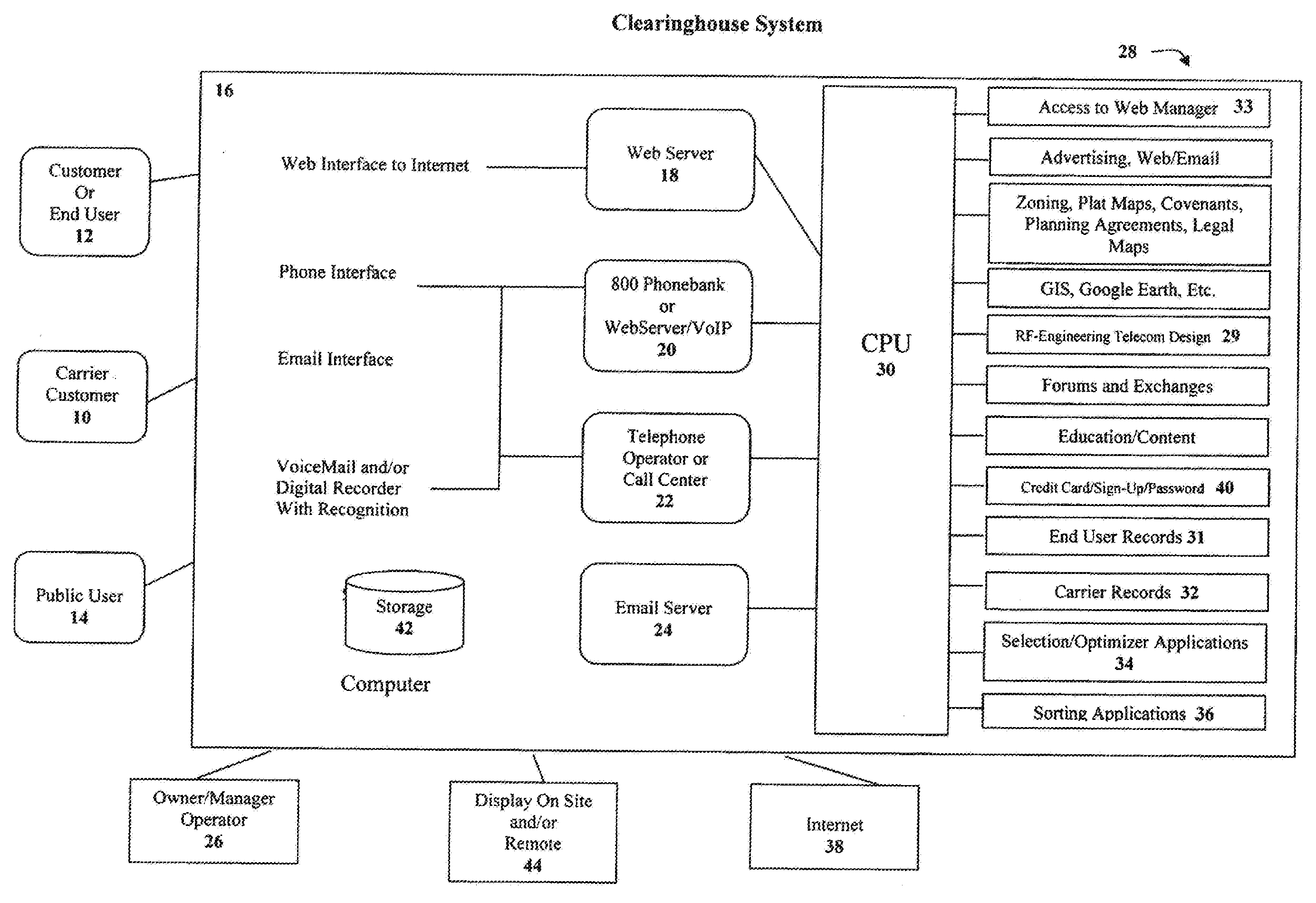

Semiconductor device and an electronic device

InactiveUS20050029648A1Reduce in quantitySuppress power noiseSemiconductor/solid-state device detailsSolid-state devicesDevice materialPower noise

A semiconductor device has a reduced number of external power terminals and is scaled down while suppressing power noise, and an electronic device is efficiently equipped with a bypass condenser. A package substrate has, on its surface, a semiconductor chip having a plurality of output circuits and at least one electrode for supplying a voltage to each of the output circuits, and is provided with external terminals on its back surface and has a plurality of wiring layers.

Owner:RENESAS ELECTRONICS CORP

Clearinghouse System and Method for Enhancing the Quality, Operation and Accessibility of Carrier-Based Networks

InactiveUS20100250268A1Broaden their knowledgeLow costDigital data processing detailsError detection/correctionTelecommunications networkCommunications system

A computerized system, method and process allows telecommunications carriers to find, evaluate and select locations for equipment through direct access to end users, while providing citizens the opportunity to offer the use of their dwelling or other assets to carriers. The system and method further provides a computerized mechanism for (a) creating an inventory and marketplace for available properties for use in telecommunications networks, (b) providing quality and / or performance monitoring and control for wireless communication systems based on data in the clearinghouse, and (c) providing localized content over wireless networks using the clearinghouse.

Owner:RAPPAPORT THEODORE S

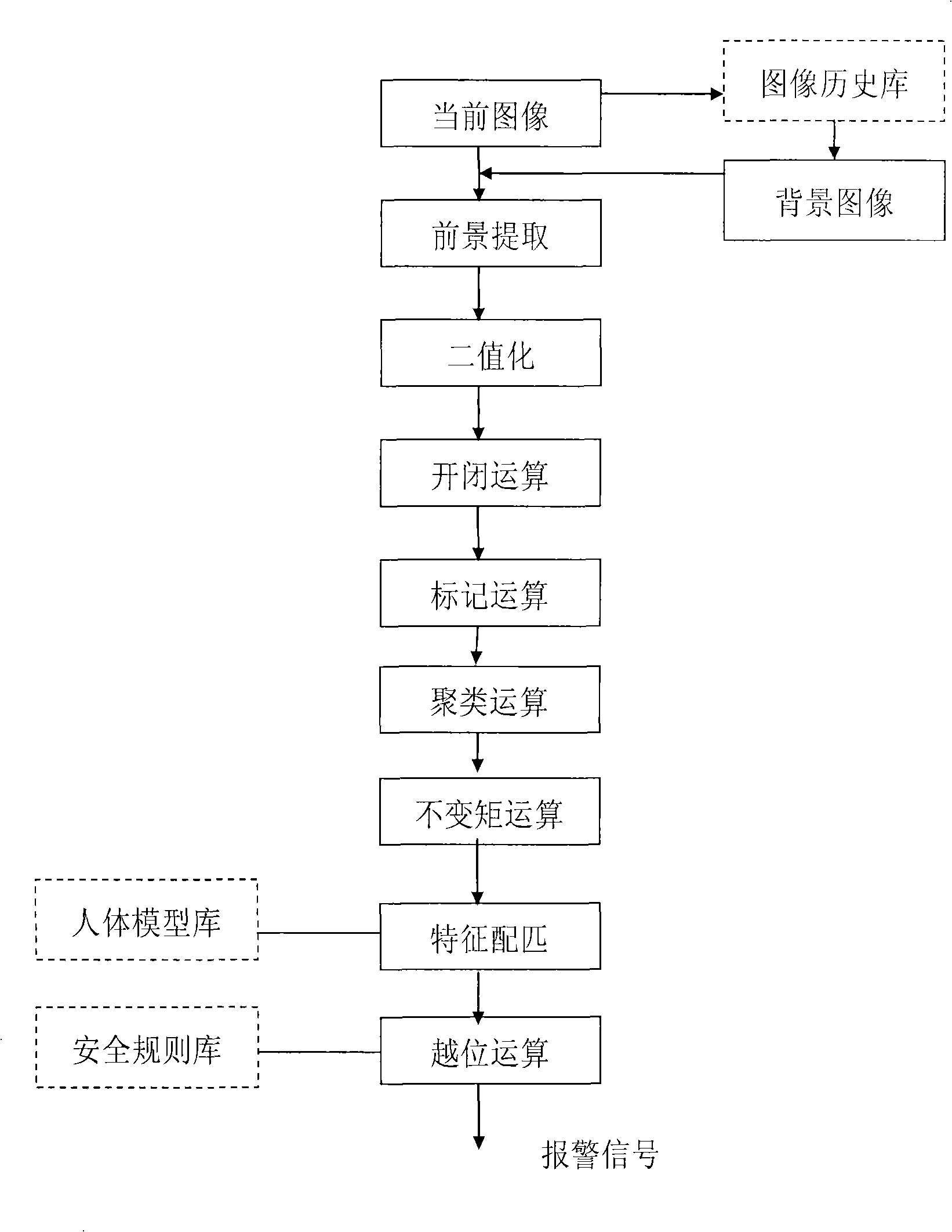

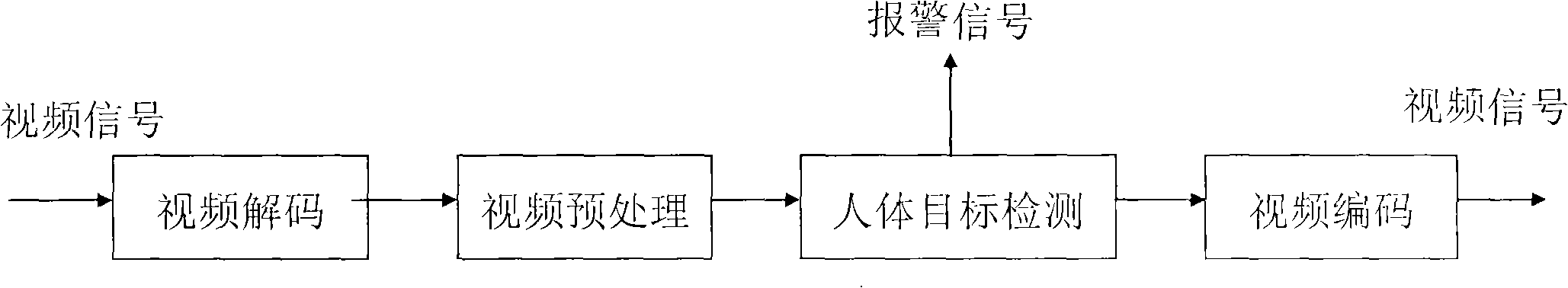

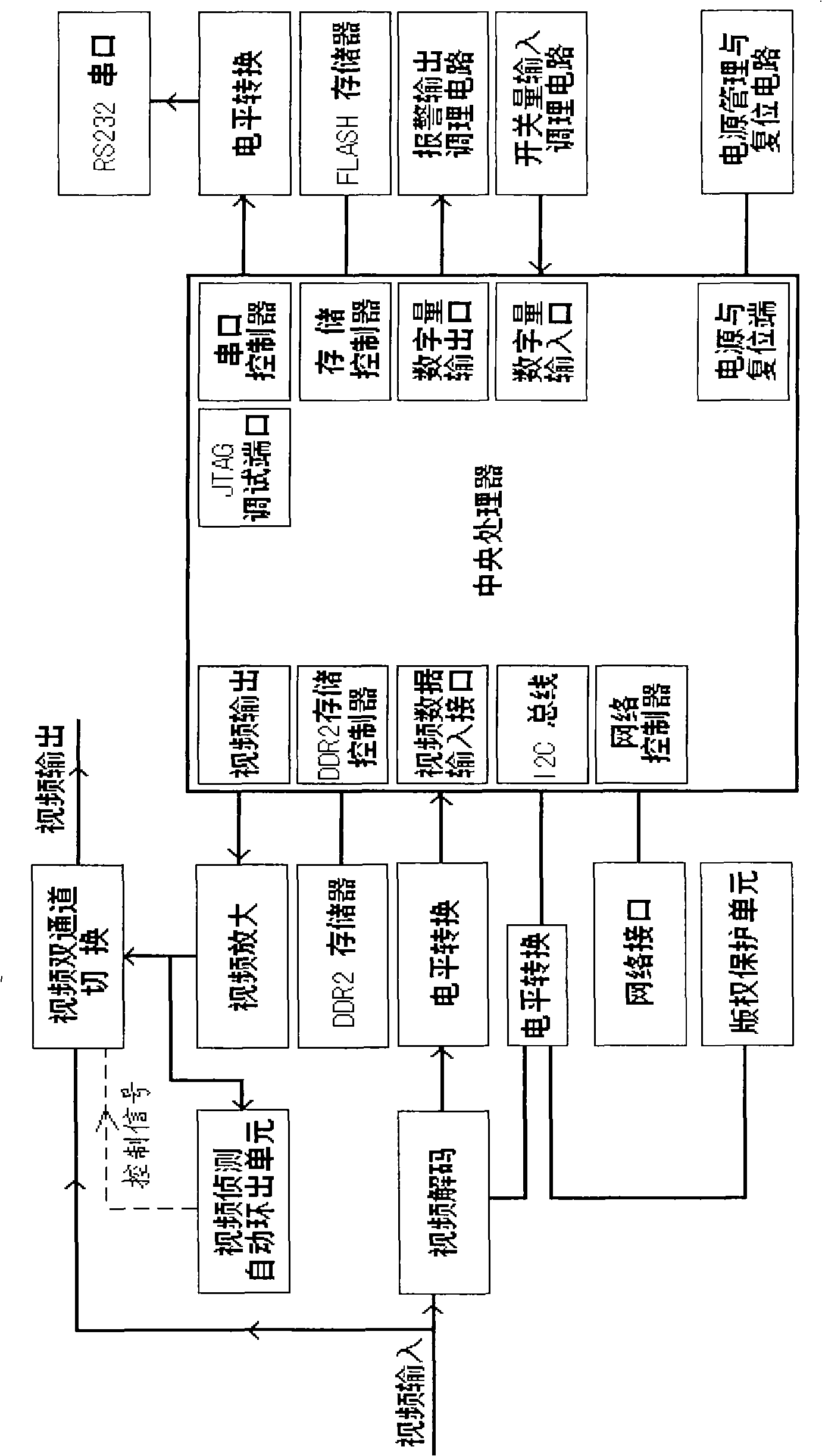

Novel method and device for safety supervising of human body moving target video frequency detection

InactiveCN101251941AStrong real-time processing abilityEquipment efficientBurglar alarmHuman bodySecurity rule

The invention provides a novel and reliable method used for detecting a video of human moving target and a device thereof, which accurately identifies a human moving target by using a technology of dynamic cluster and moment invariants based on human body models, monitors the behavior of a human body according to a preset safety regulation and sends out an alarm. The device adopts TMS320DM6446 as a platform of core software and hardware, a high-performance dual-core structure and a platform tool of a chip guarantee that the device not only has a powerful capability of real-time processing, but also has an excellent function of peripheral management. The device can be used in the prior video monitoring system, and has strong universality and advancement for application.

Owner:JIANGSU WISCOM TECHNOLOGY CO LTD +1

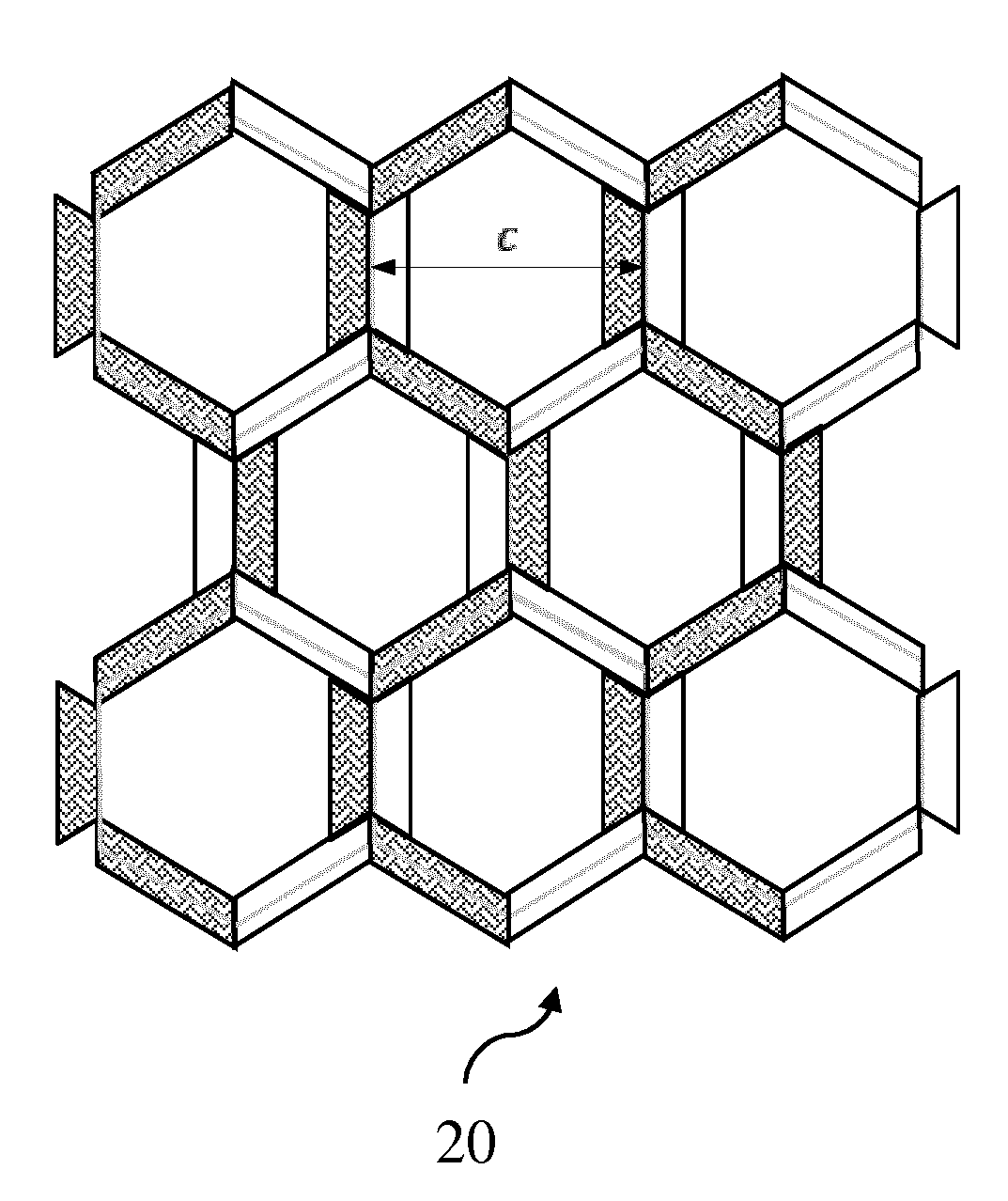

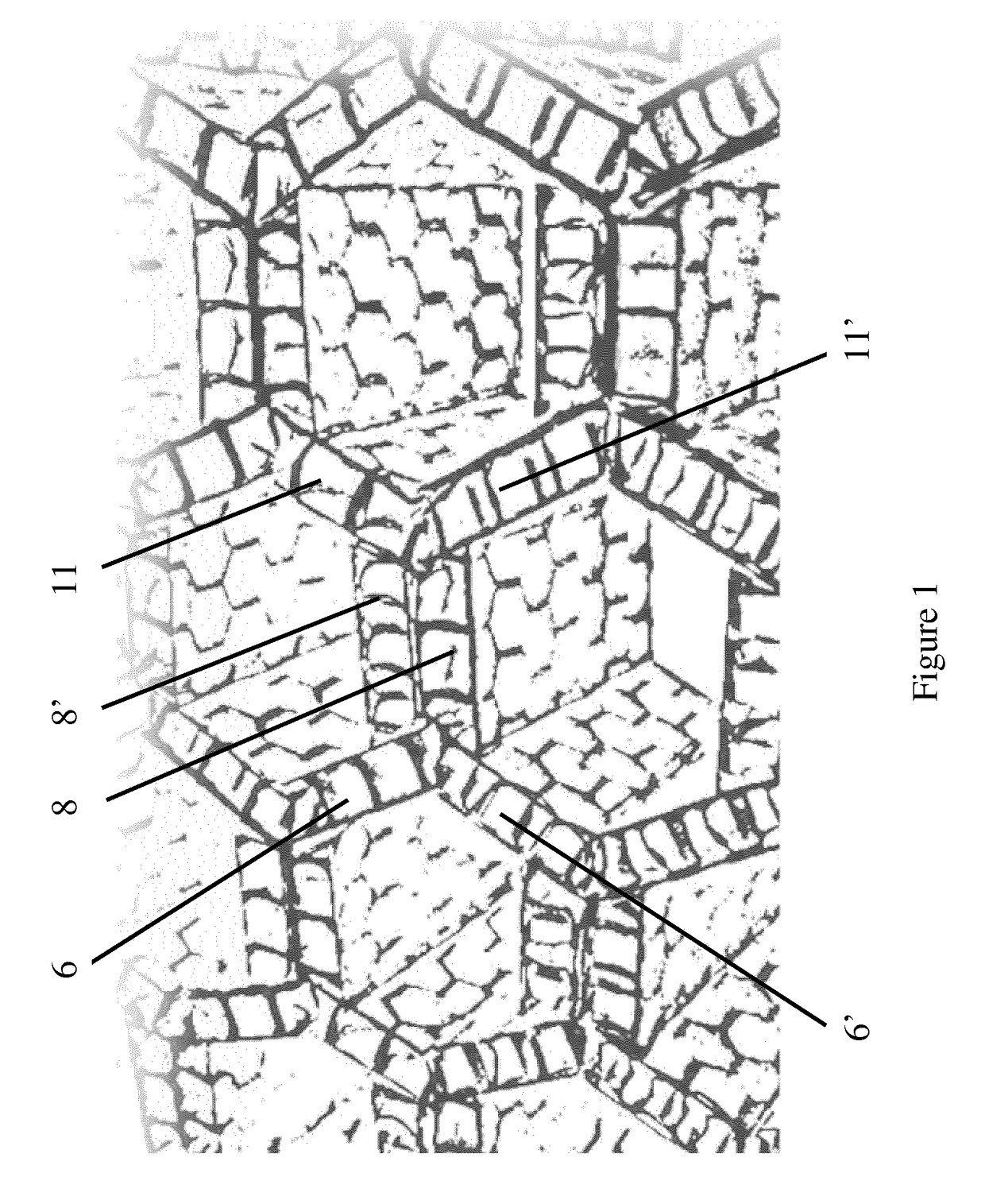

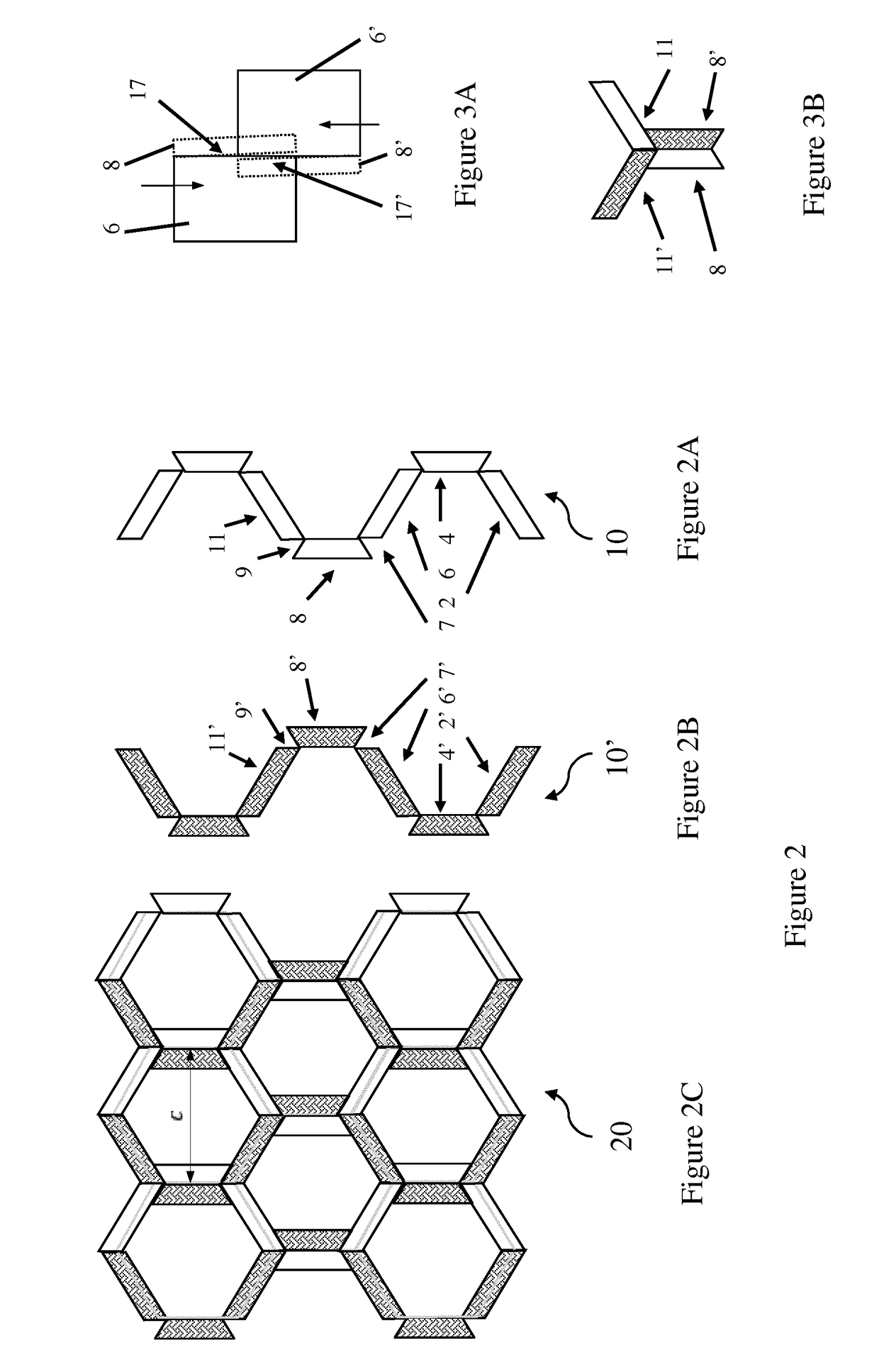

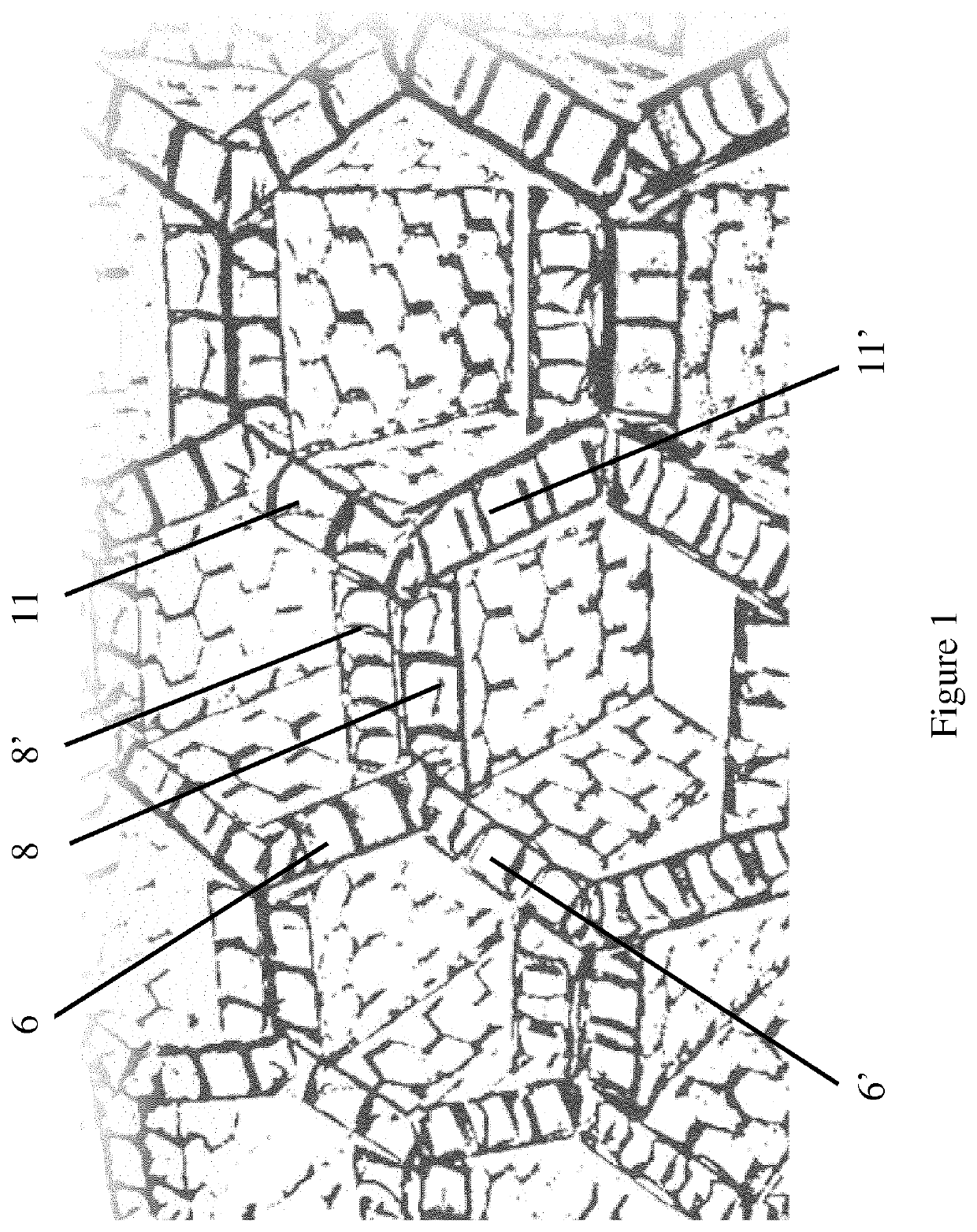

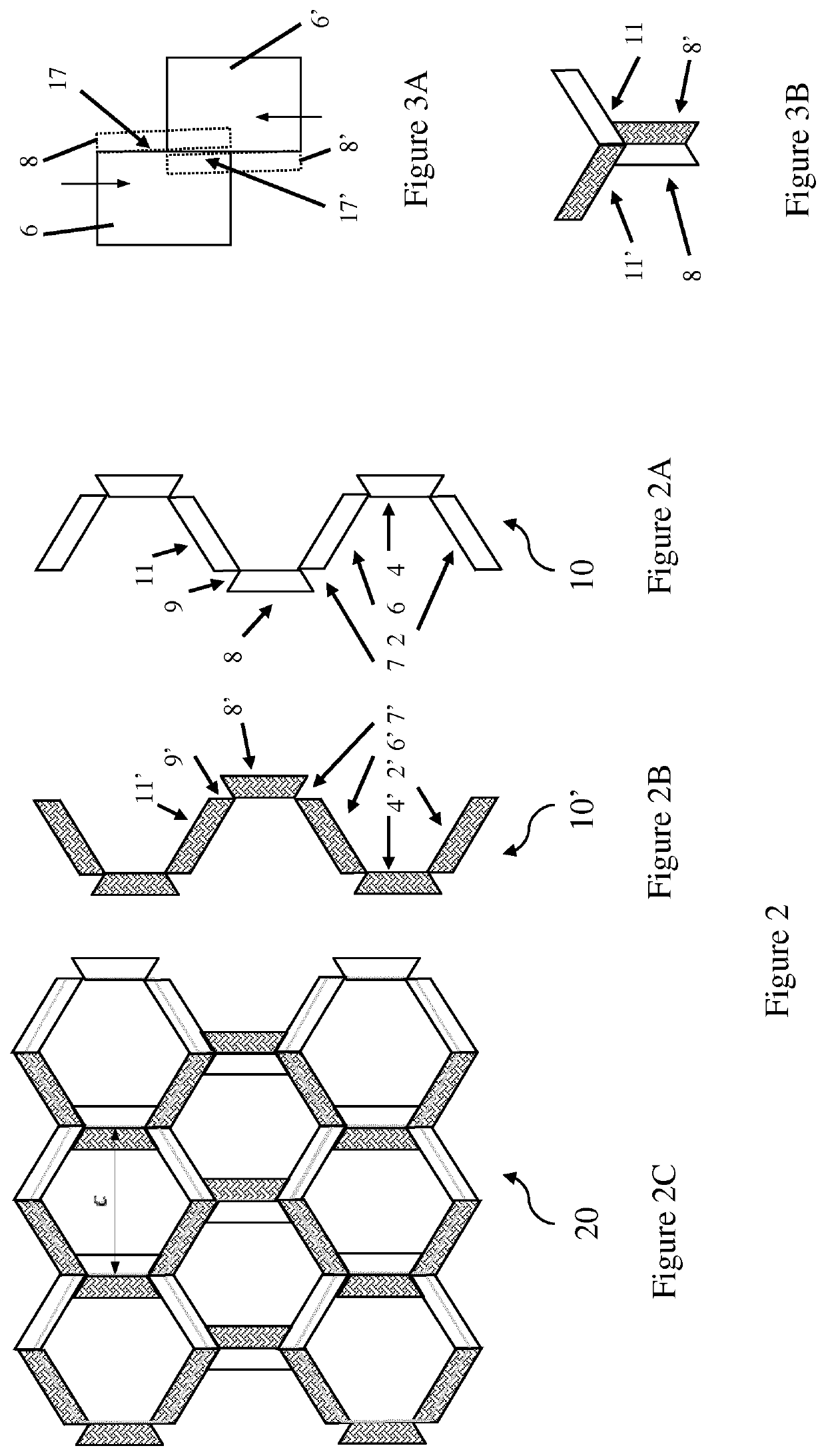

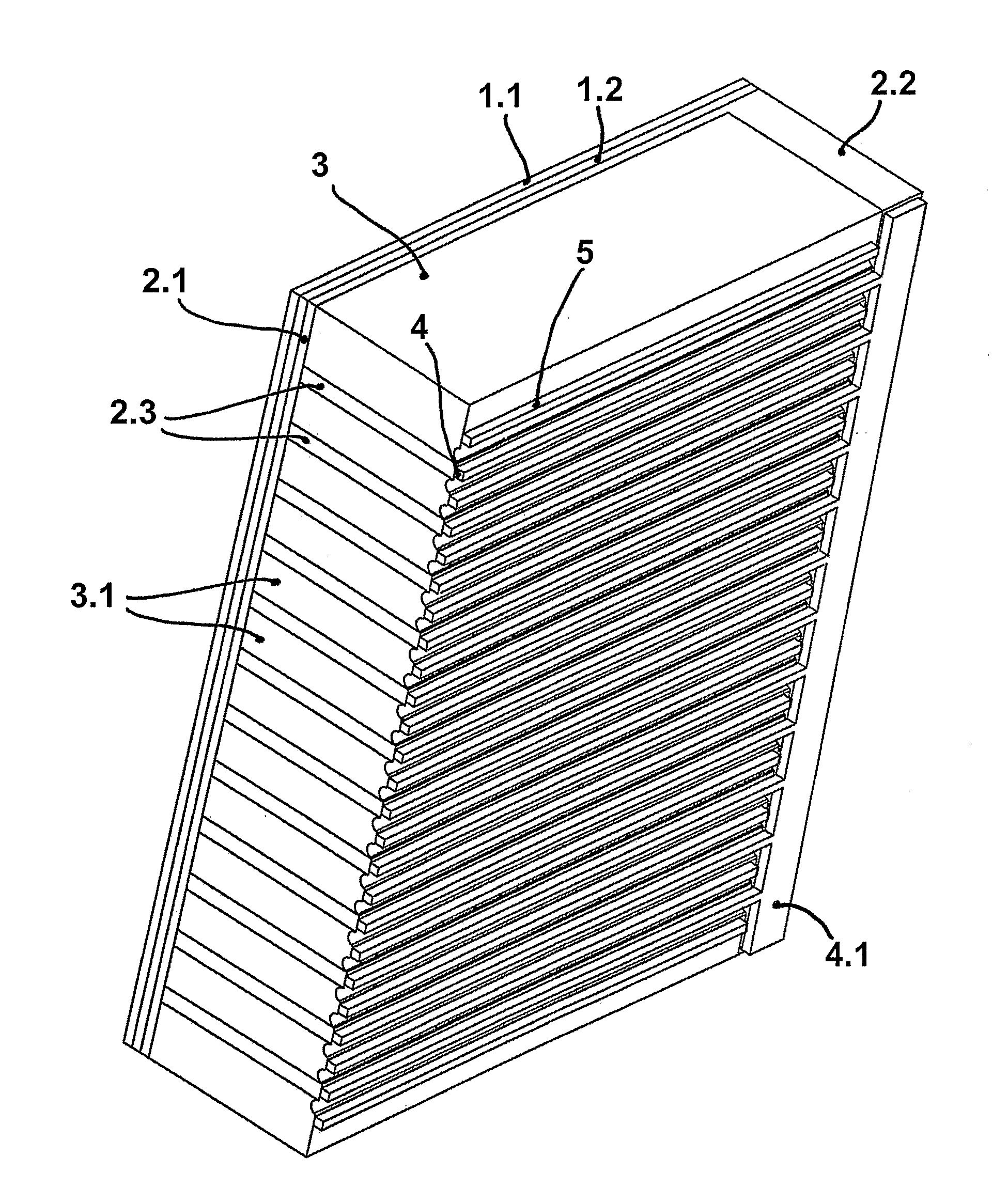

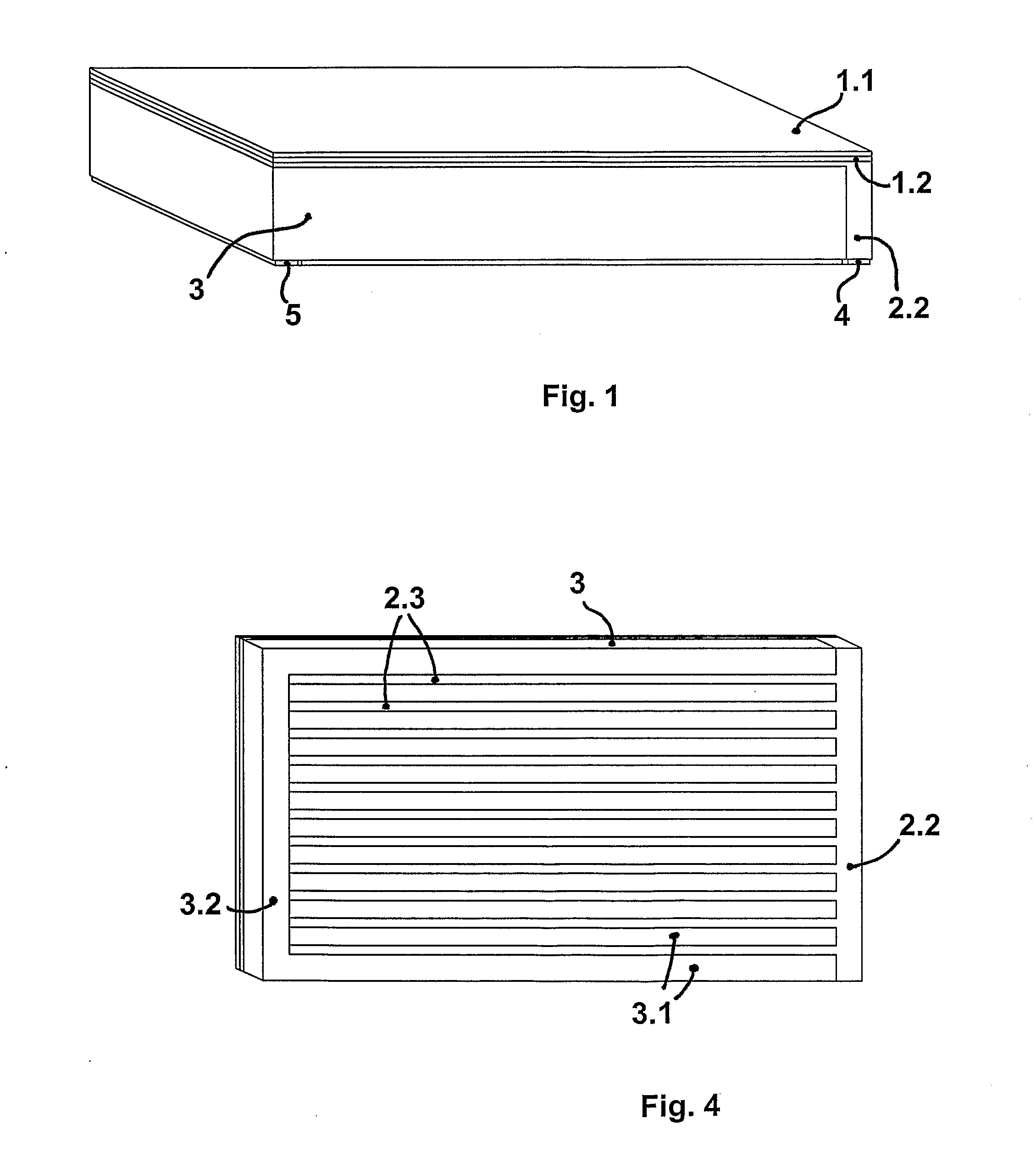

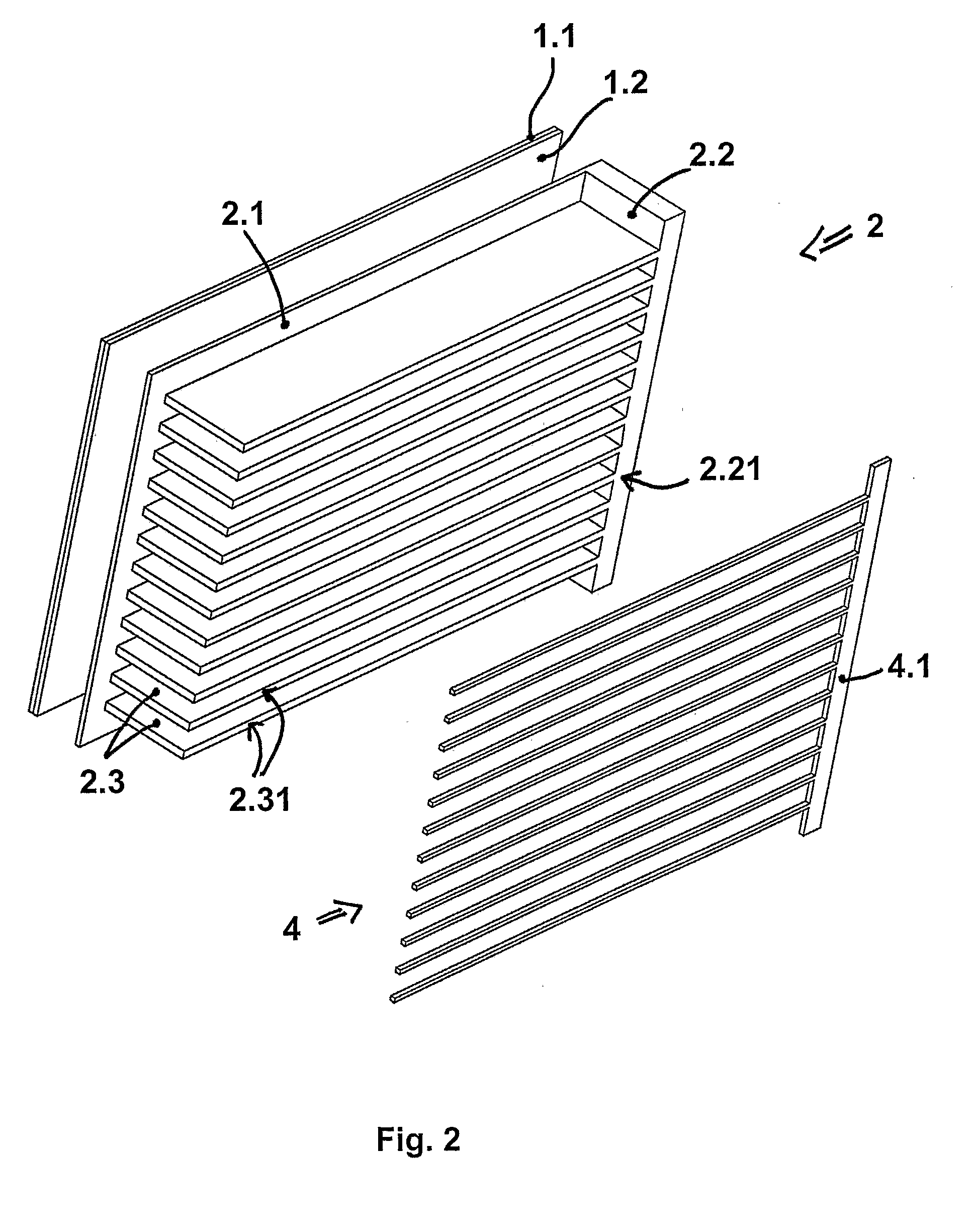

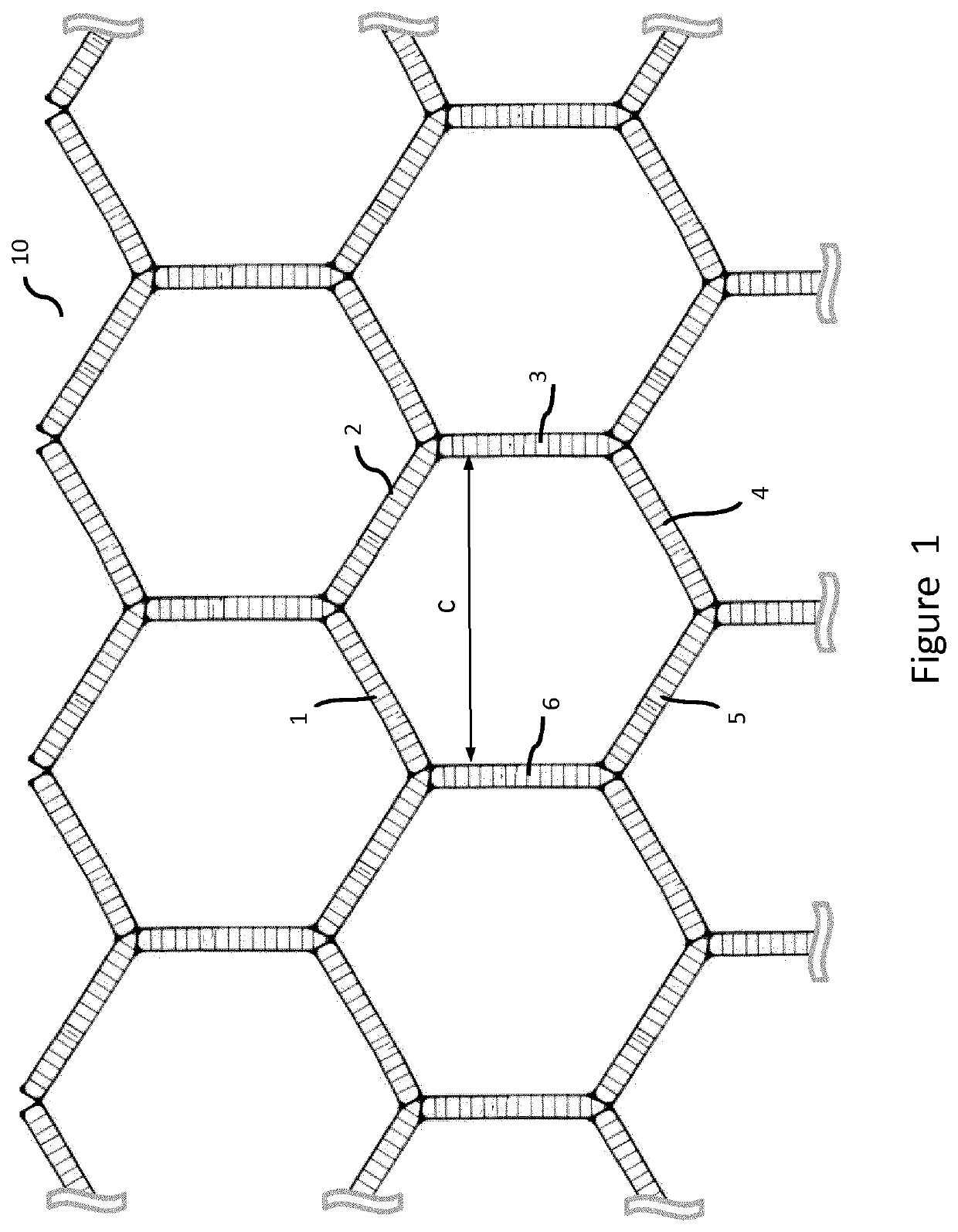

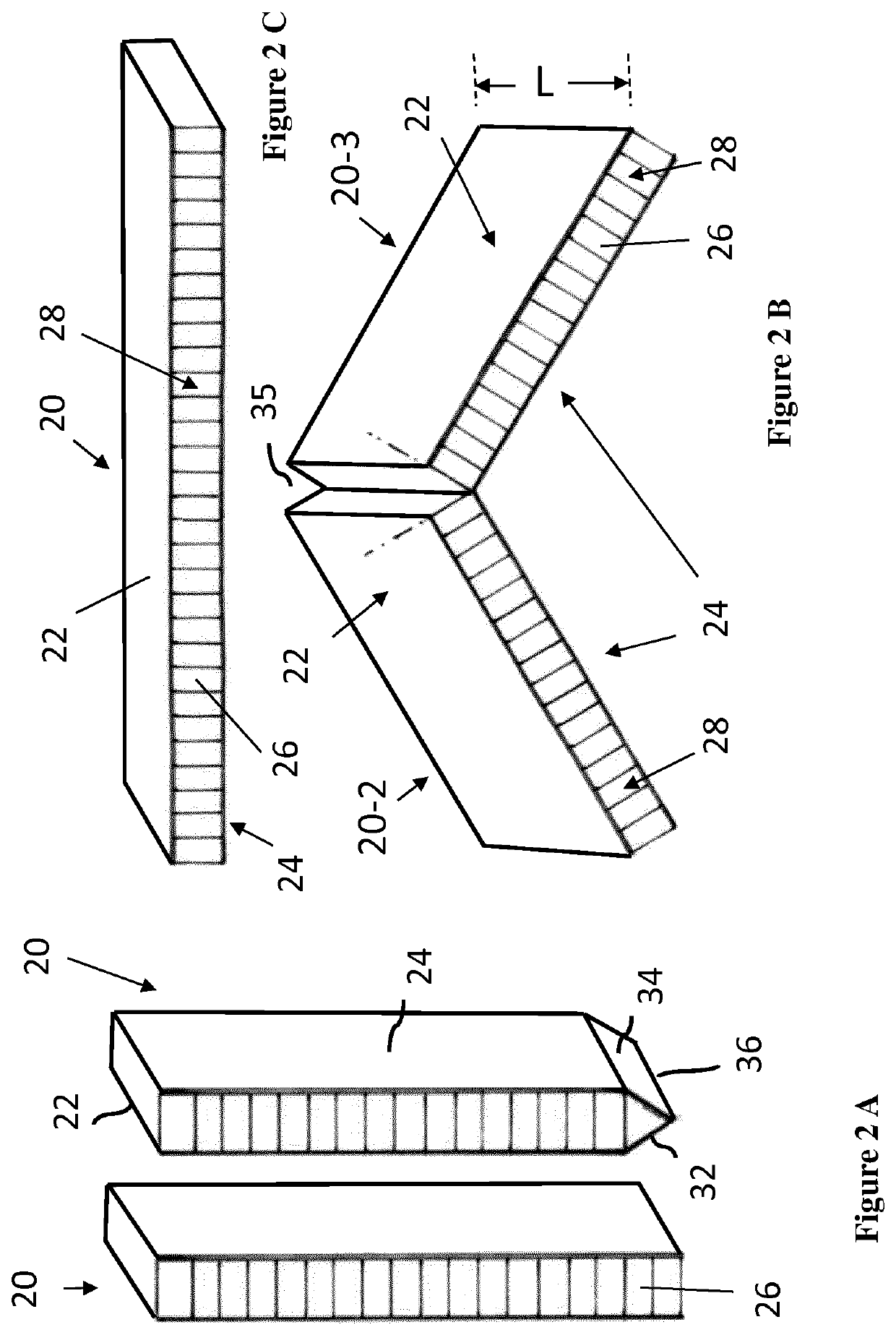

Honeycomb core with hierarchical cellular structure

ActiveUS20180126680A1Low densityProcess economyPaper/cardboard articlesHollow wall articlesEngineeringCell wall

A hierarchical sandwich core in the form of a honeycomb, i.e. having repetitive and periodic lattice materials. The sandwich core can be made up of a macroscopic honeycomb structure with sandwich cell walls having a mesoscopic cellular core. The longitudinal axis of cells of the mesoscopic honeycomb cell can be perpendicular to the longitudinal axis of the cells of the macroscopic honeycomb structure. Alternatively, if a foam core is used having mesoscopic cells the shape of the mesoscopic cells can be made during the foaming process so that they are elongate in a direction perpendicular to the longitudinal axis of the cells of the macroscopic honeycomb structure.

Owner:ECONCORE NV

Apparatus for fabrication of three dimensional objects

ActiveUS10150280B2Reduce in quantityReduce forceManufacturing driving meansManufacturing enclosuresPhotosensitive polymerEngineering

An apparatus for bottom-up fabrication of three dimensional objects, the apparatus comprising: a vat for a photosensitive polymer, the floor of the vat including a working surface arranged such that, in use, light incident on the working surface interacts with the photosensitive polymer at the working surface to fabricate a portion of the three dimensional object; a build platform capable of being inserted into the vat, the build platform having a planar surface; an elevator mechanism capable of adjusting the separation between the working surface of the vat and the planar surface of the build platform; and a rotation mechanism capable of varying the relative rotational position of the vat relative to the build platform, the relative rotation being about an axis which is normal to the working surface of the vat.

Owner:HOLO INC

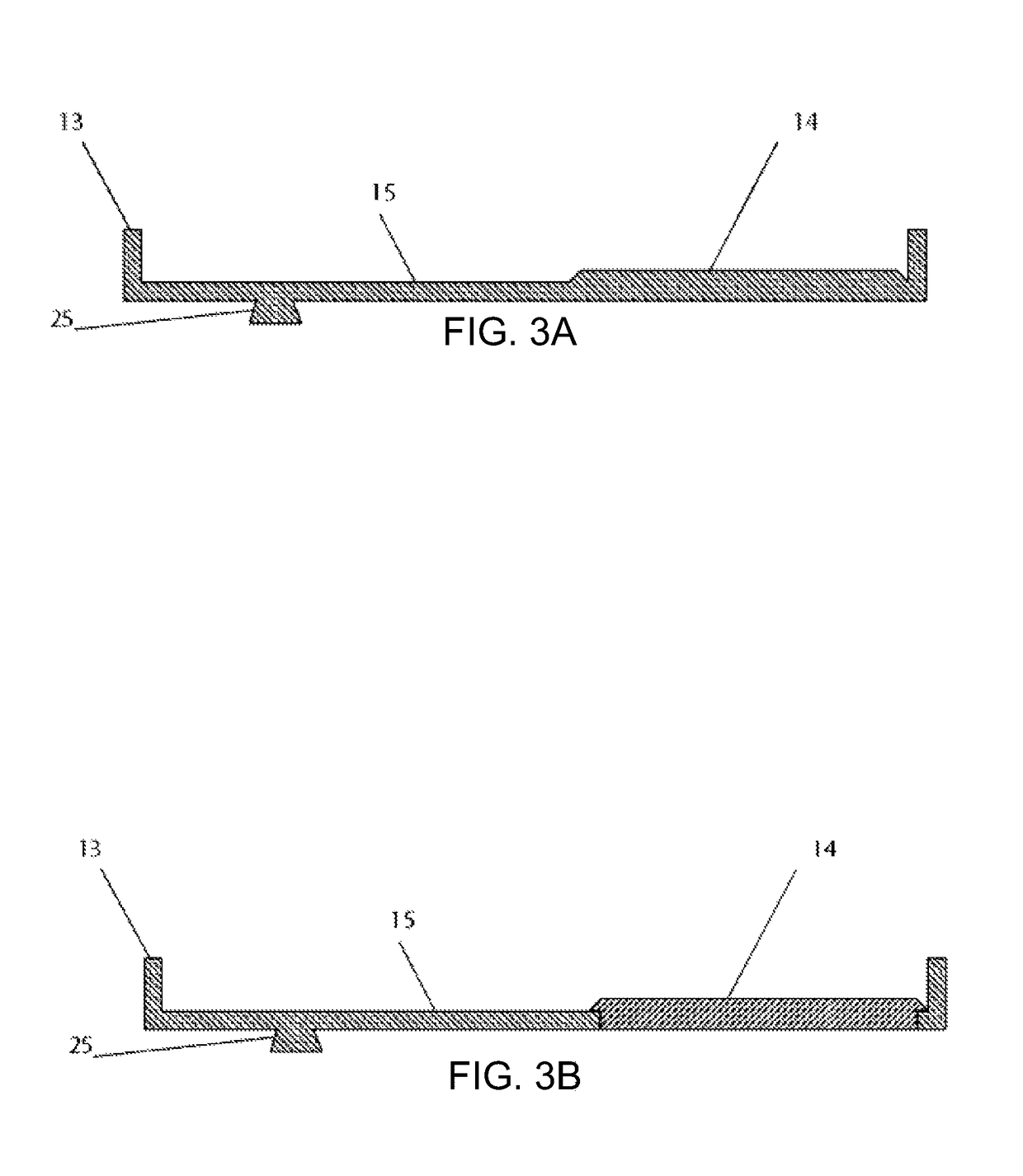

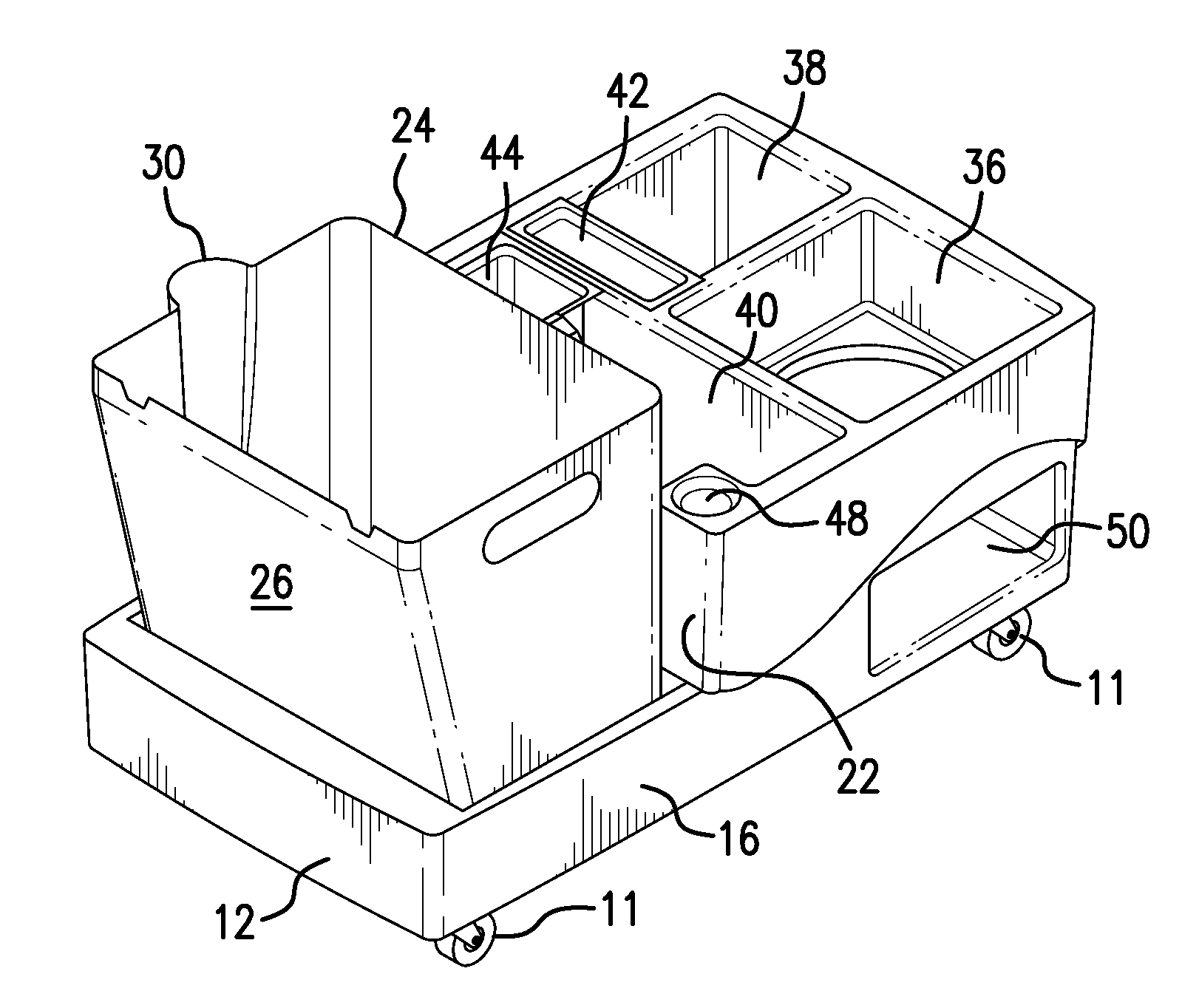

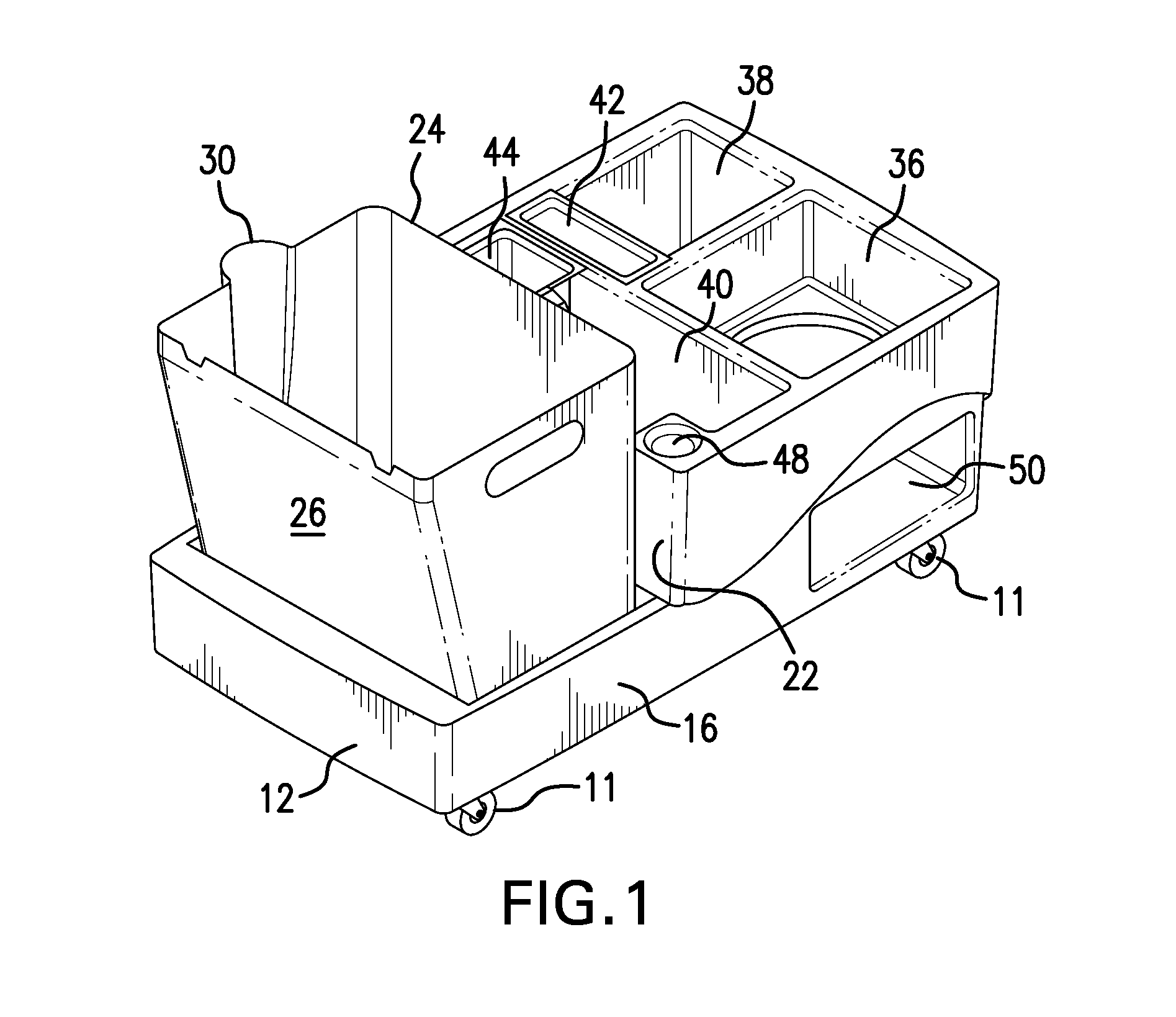

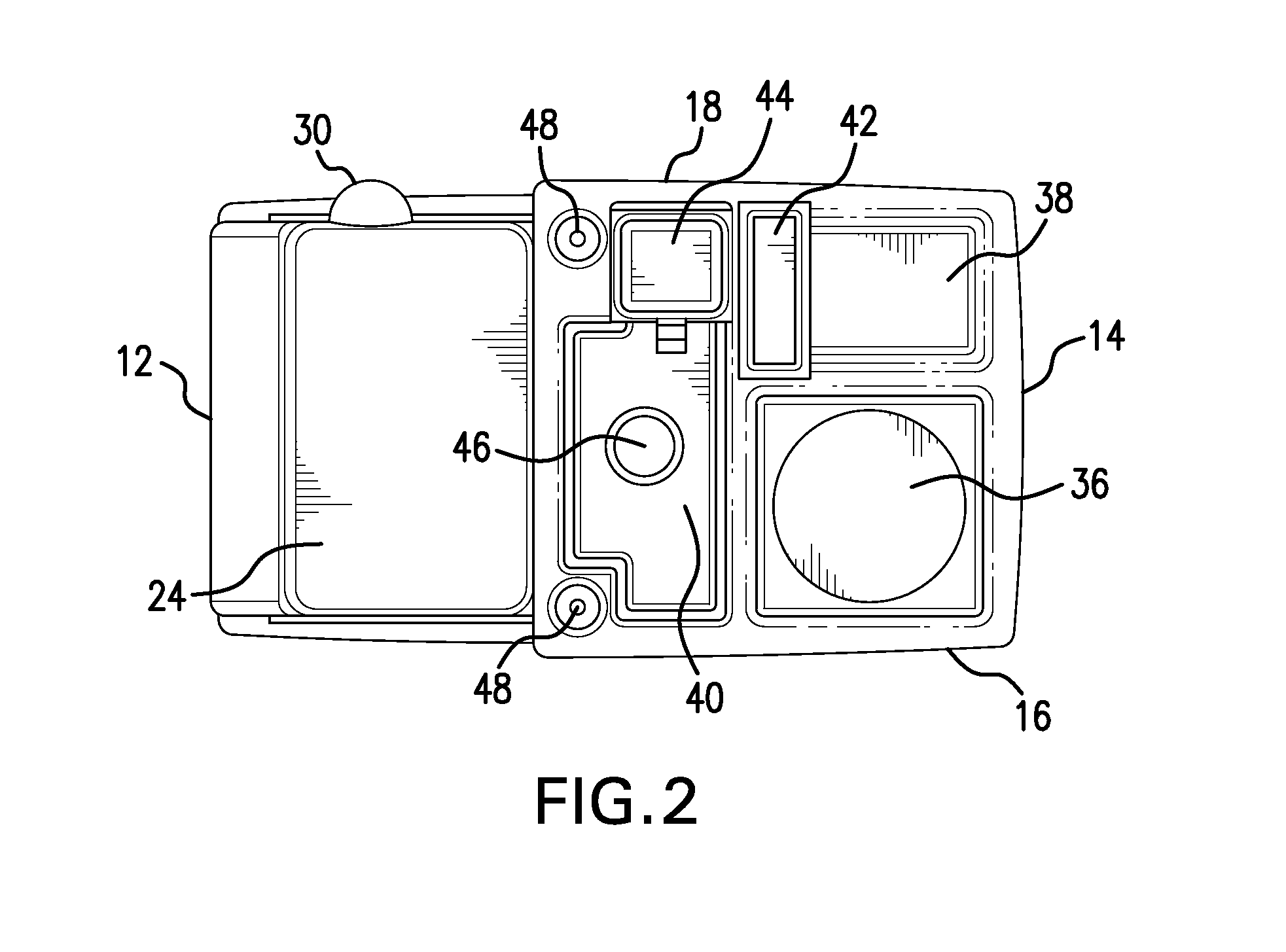

Multipurpose mobile caddy

ActiveUS9393979B1Efficient apparatusEasy to workWork benchesHand carts with multiple axesEngineeringMechanical engineering

Owner:MILTON DENEEN

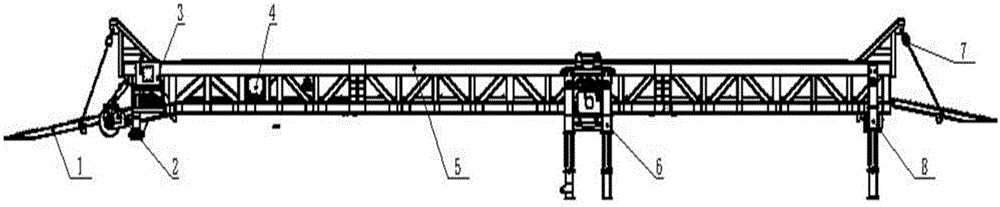

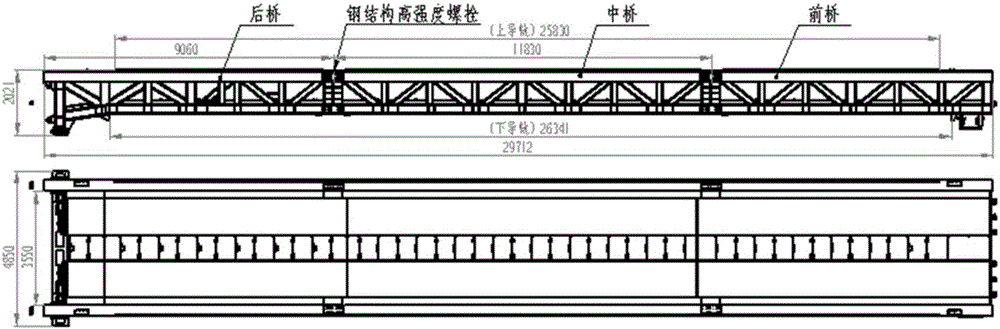

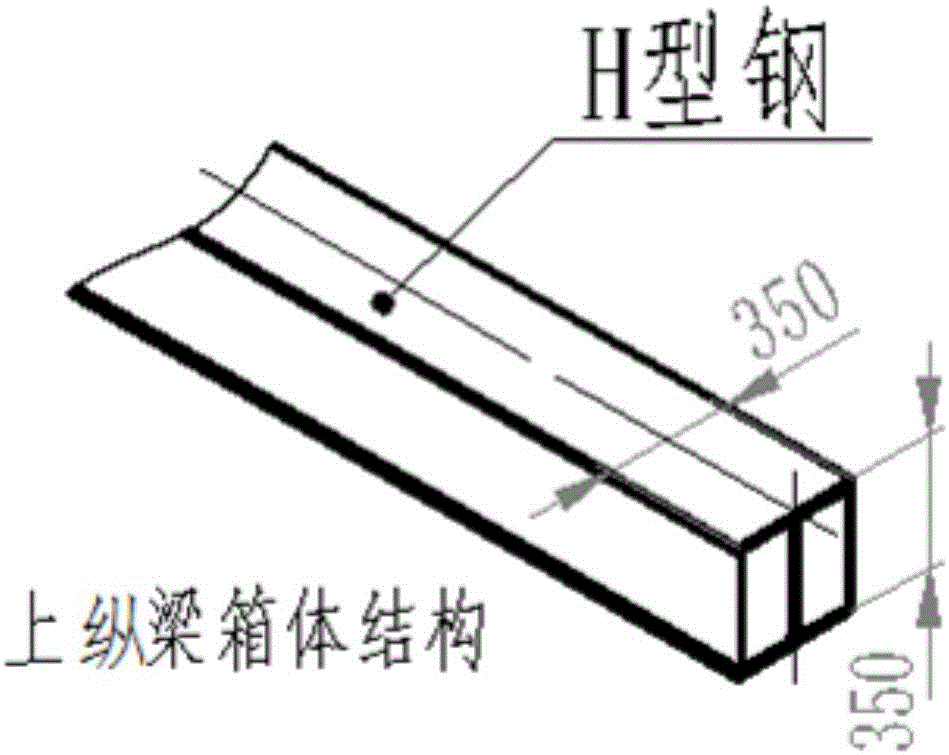

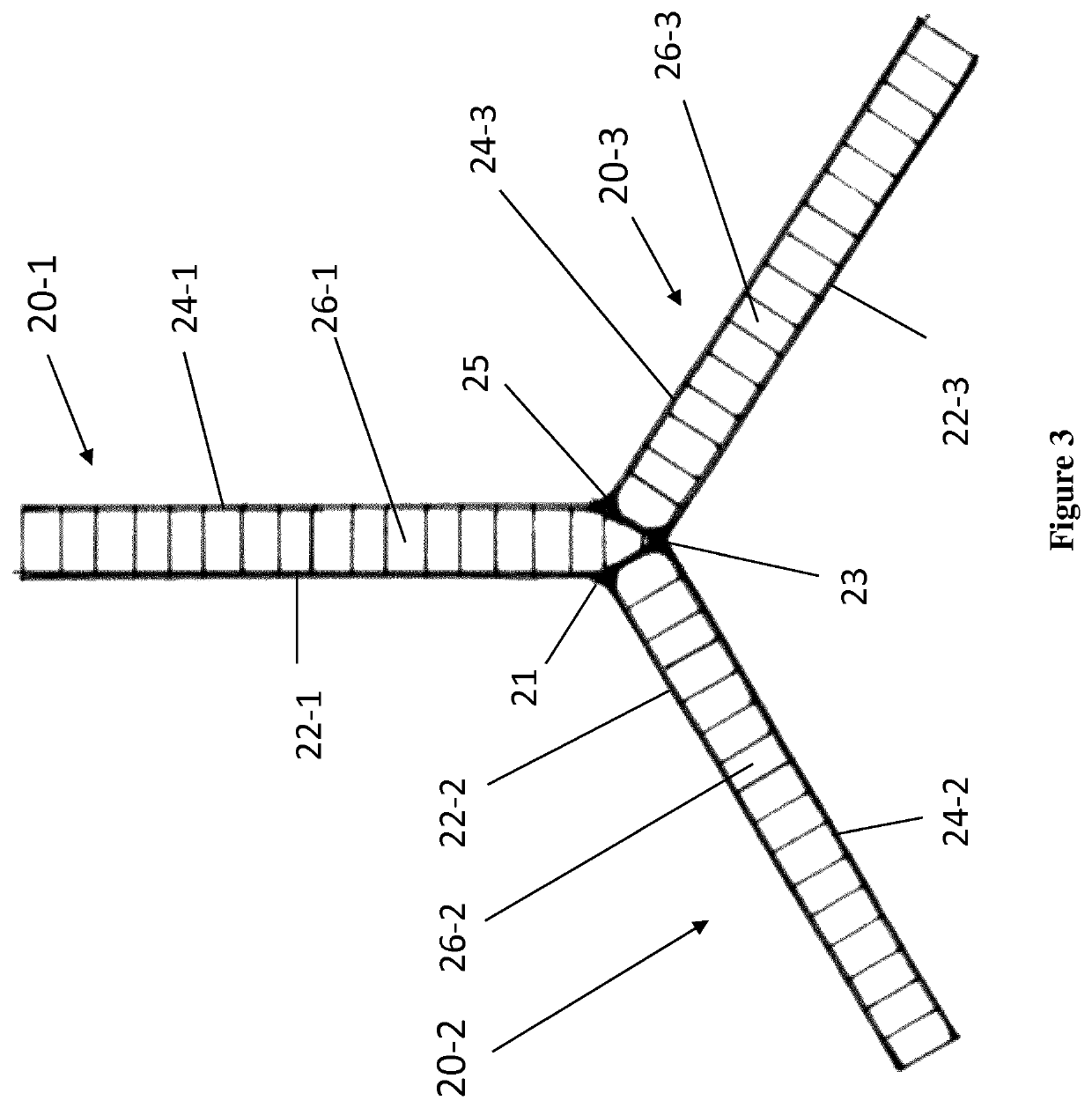

Moveable trestle with stepping type self-walking truss structure for large-section tunnel invert construction

InactiveCN106593471AEquipment efficientReduce construction preparation timeUnderground chambersTravelling bridgesEngineeringHigh intensity

Owner:CHINA RAILWAY NO 5 ENG GRP +1

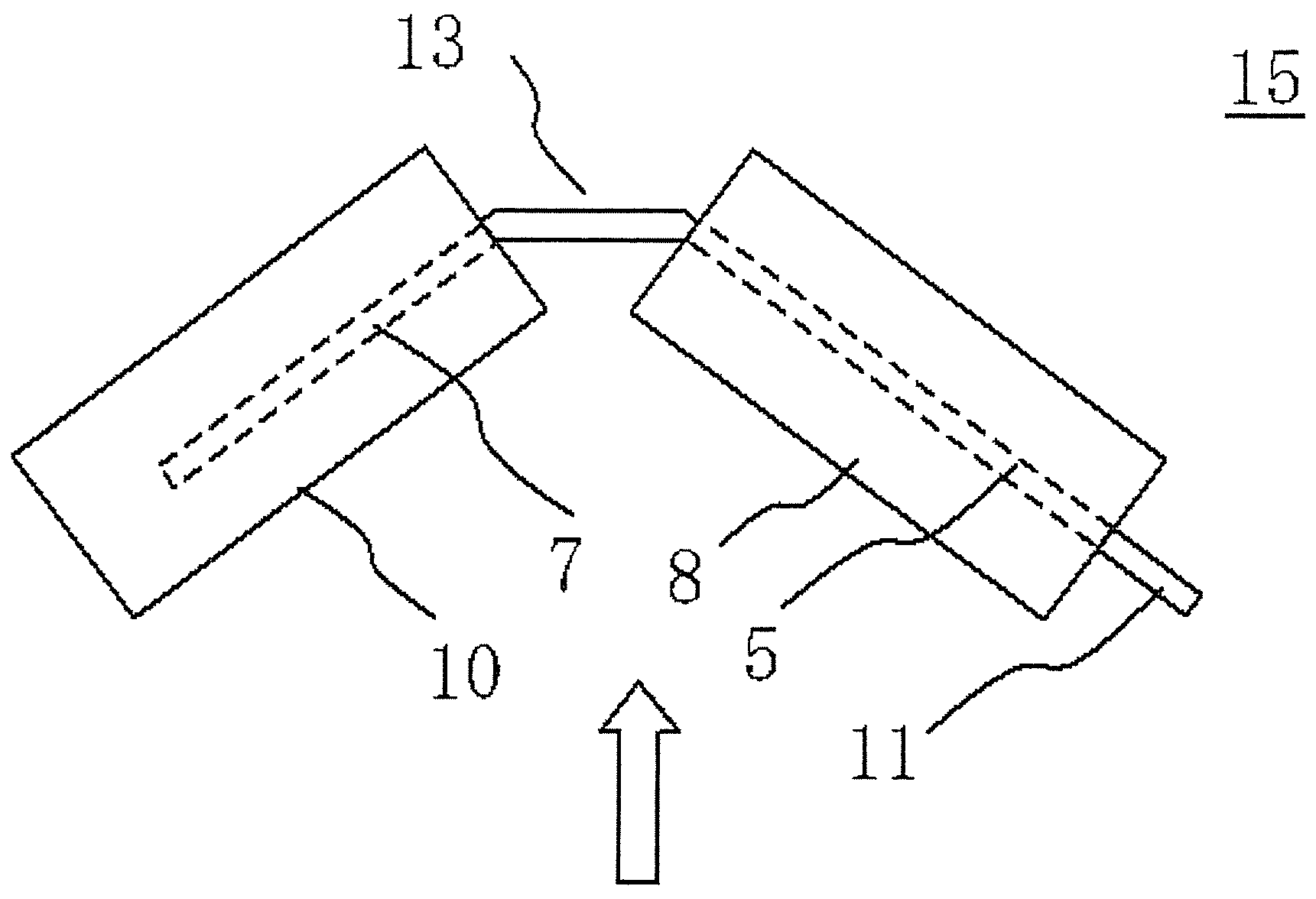

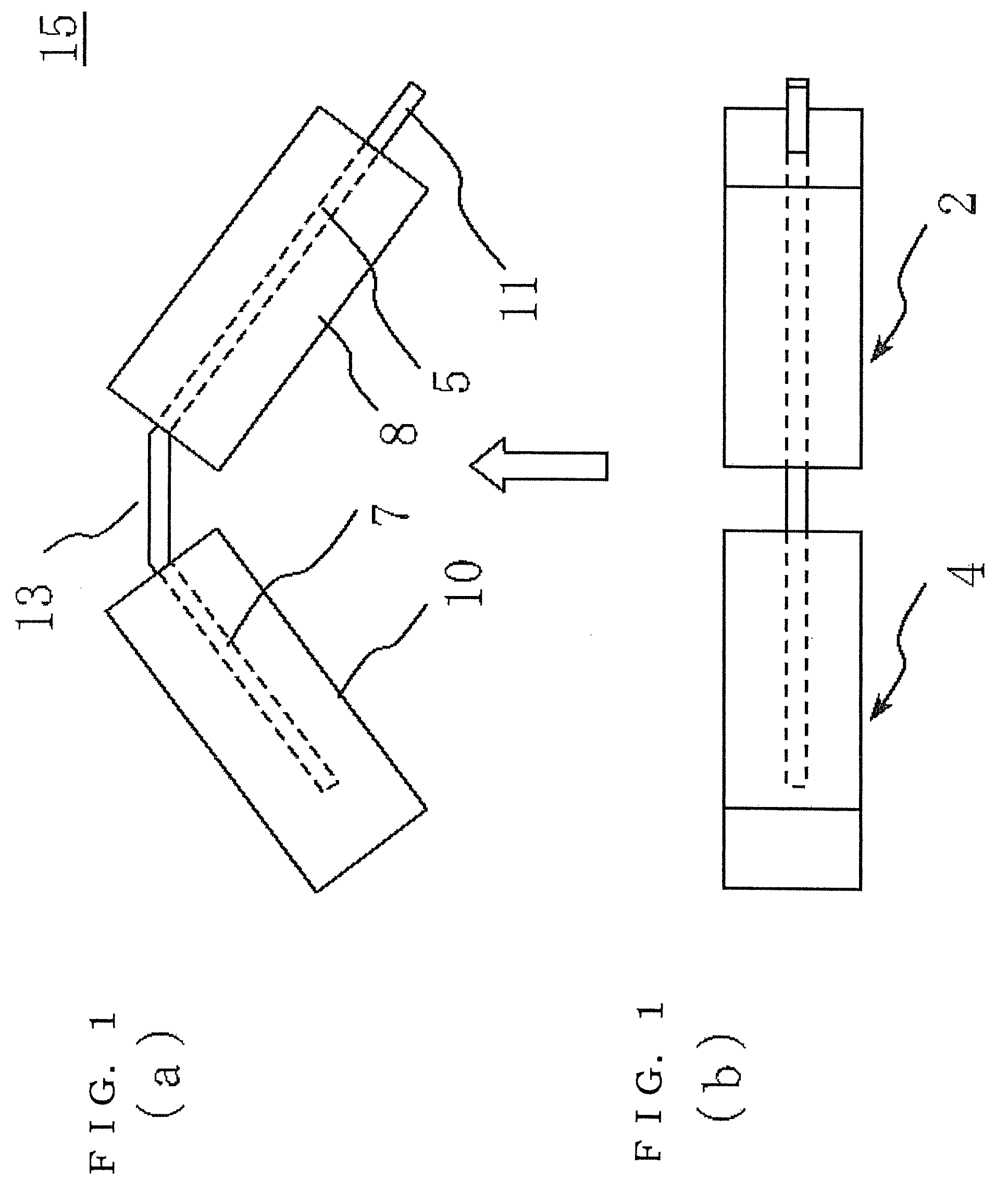

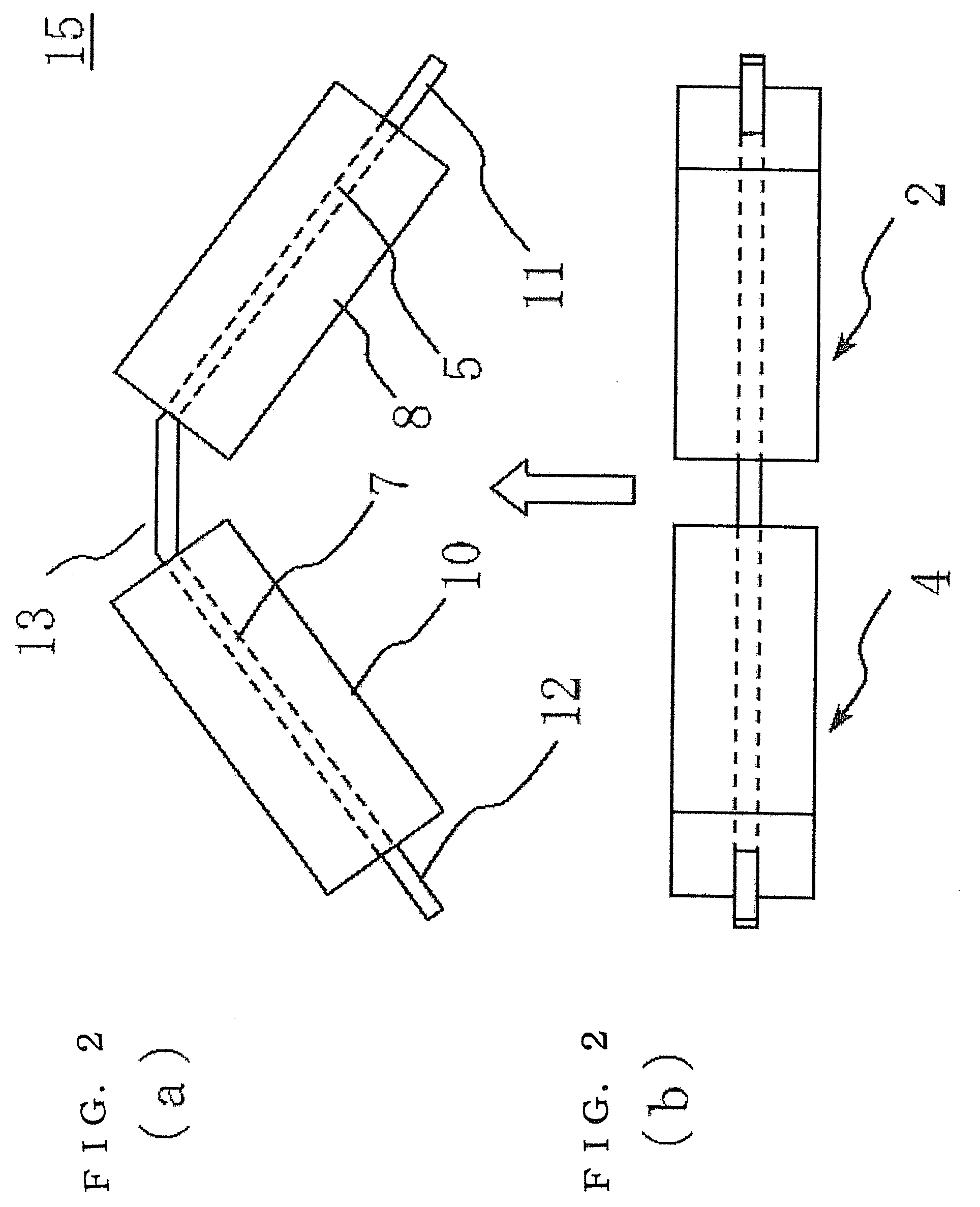

Chip antenna, an antenna device, and a communication equipment

ActiveUS7701399B2High bandwidthSolve narrow bandwidthSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorElectrical connection

The chip antenna shown is provided with two chip antenna elements (the 1st chip antenna element 4, the 2nd chip antenna element 2). These chip antenna elements have the 1st magnetic base 10 and the 2nd magnetic base 8, and linear conductors 7 and 5 formed in the core, respectively. Magnetic base 10 and magnetic base 8 are separated. In the 1st chip antenna element 4, linear conductor 7 formed in the core of the 1st magnetic base 10 was formed to the end face of this magnetic base, and the end has protruded from said end face. On the other hand, in the 2nd chip antenna element 2, linear conductor 5 formed in the core of the 2nd magnetic base 8 has penetrated magnetic base 8. Furthermore, conductor 7 in the 1st chip antenna element and conductor 5 in the 2nd chip antenna element are electrically connected mutually in series by connection conductors 13 arranged among these chip antenna elements.

Owner:HITACHI METALS LTD

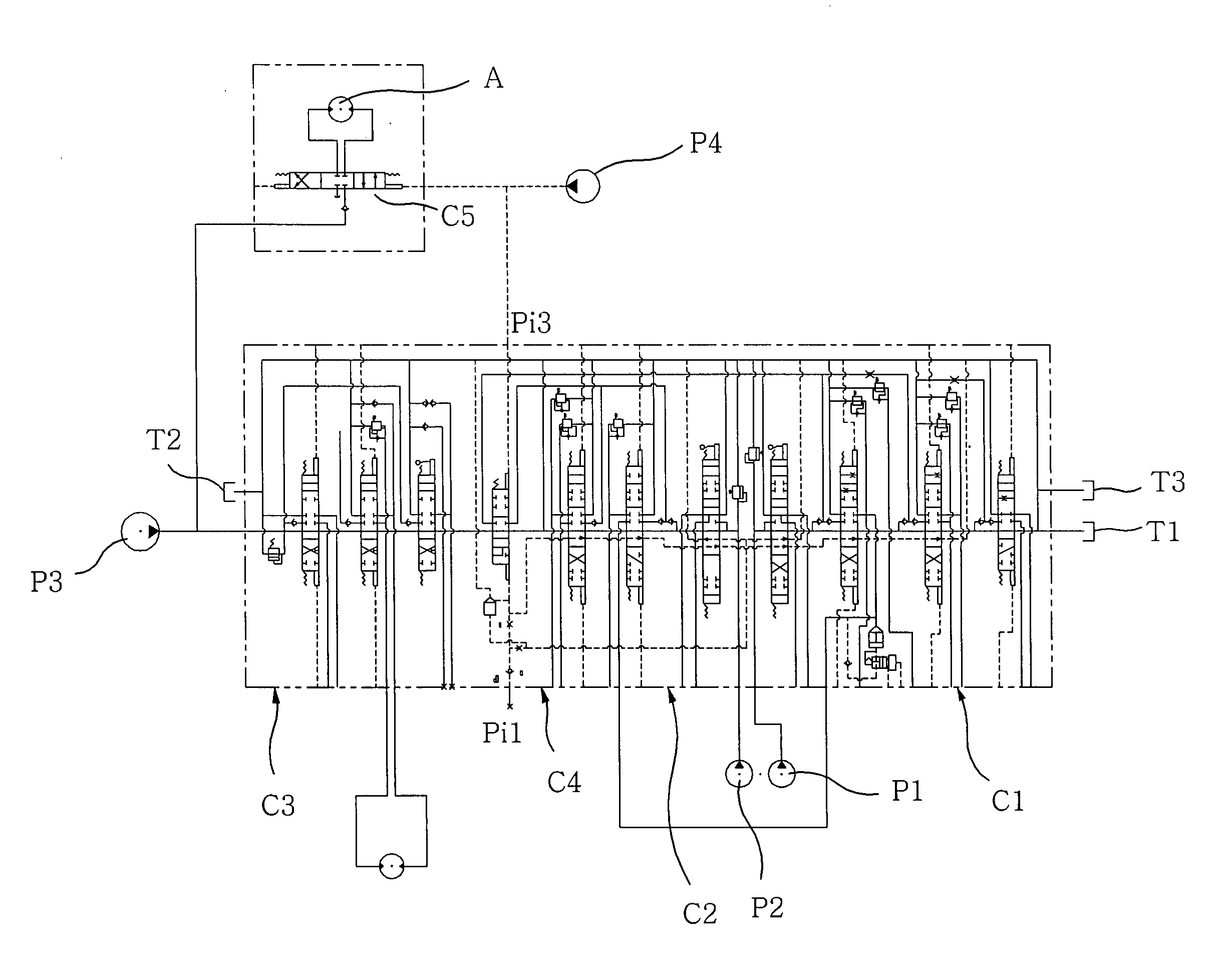

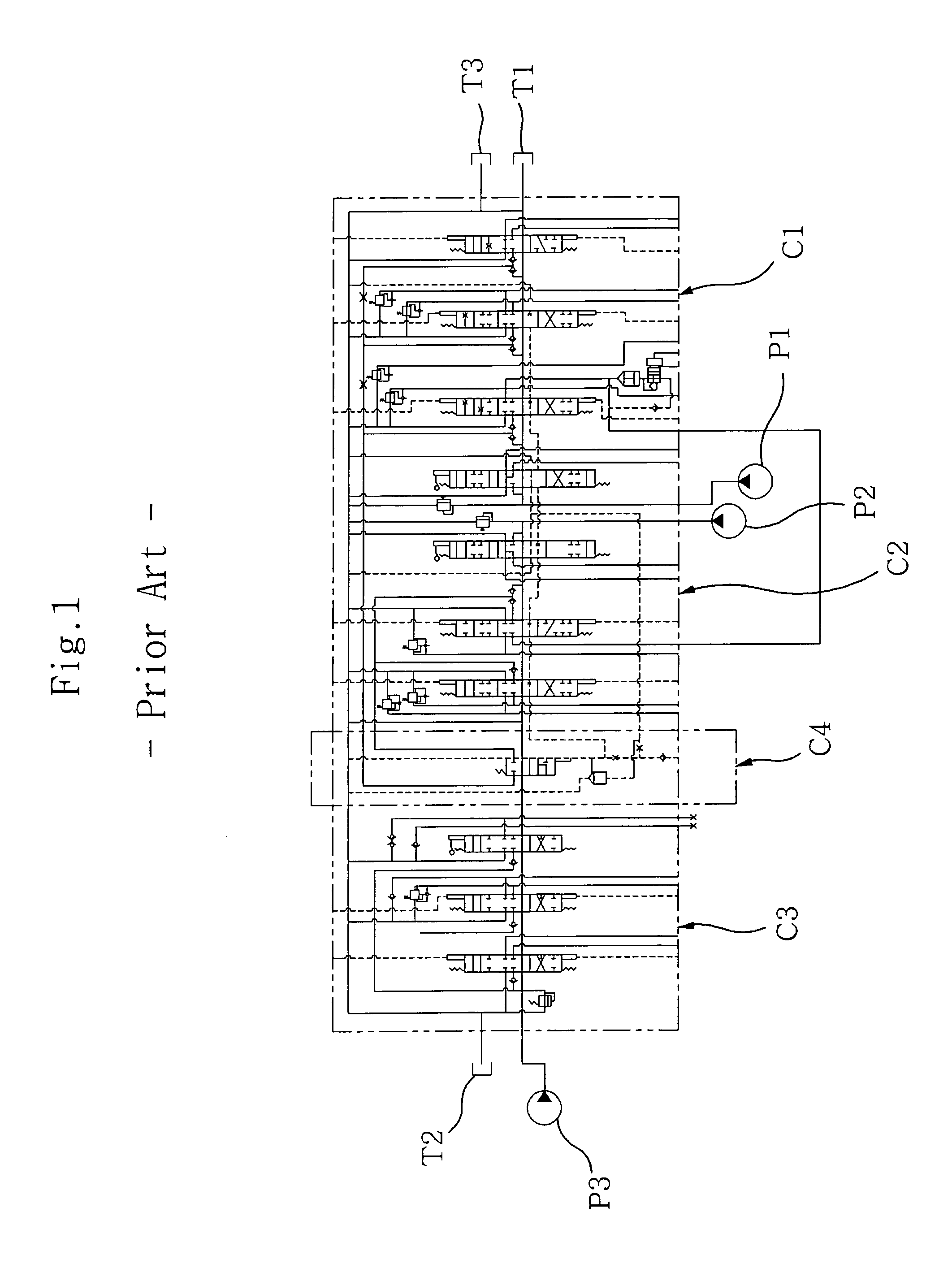

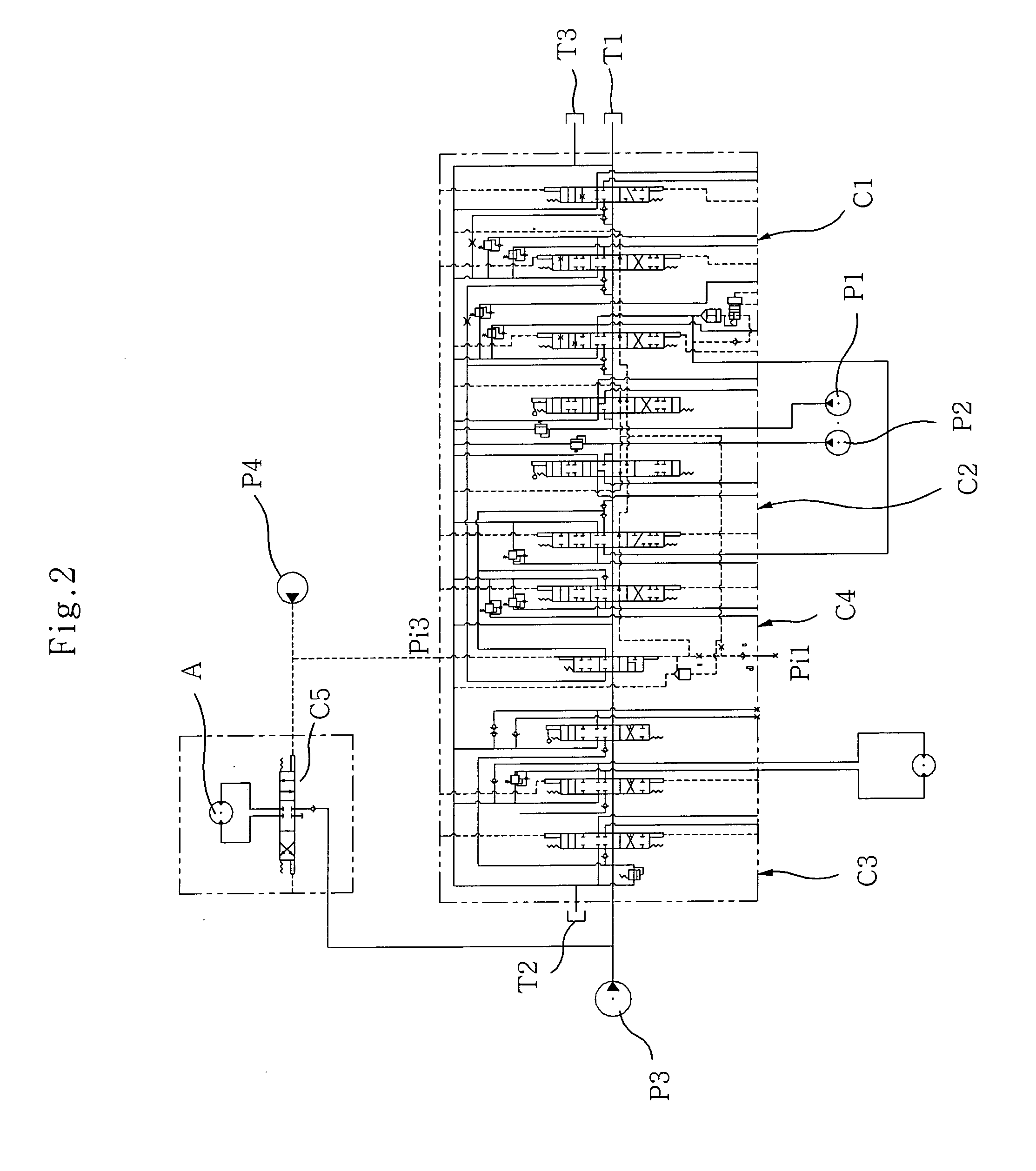

Hydraulic system for heavy equipment option apparatus

ActiveUS7155908B2Lower unit costDecreasing cost fabrication costFluid couplingsServomotorsHydraulic pumpHeavy equipment

The present invention is directed to controlling an operation oil supplied to an option apparatus without changing a design of a control valve assembly which controls an operation oil supplied to a traveling motor, etc. when additionally engaging an option apparatus to a small size excavator. In a hydraulic system for a heavy equipment which includes a plurality of hydraulic pumps, a main control valve which is switched by a pilot signal pressure and controls an operation oil supplied to a left and right side traveling motor and a work apparatus, and a pilot pump which supplies a pilot signal pressure to the main control valve, there is provided a hydraulic system for a heavy equipment option apparatus which includes a straight traveling control valve which combines an operation from a plurality of the hydraulic pumps and supplies to the left and right side traveling motors and disconnects an operation supplied to the traveling motor when the same is switched by a pilot signal pressure, and an option apparatus control valve which is switched concurrently with the straight traveling control valve by a pilot signal pressure and controls an operation oil supplied from one side hydraulic pump to an additional option apparatus.

Owner:VOLVO CONSTR EQUIP

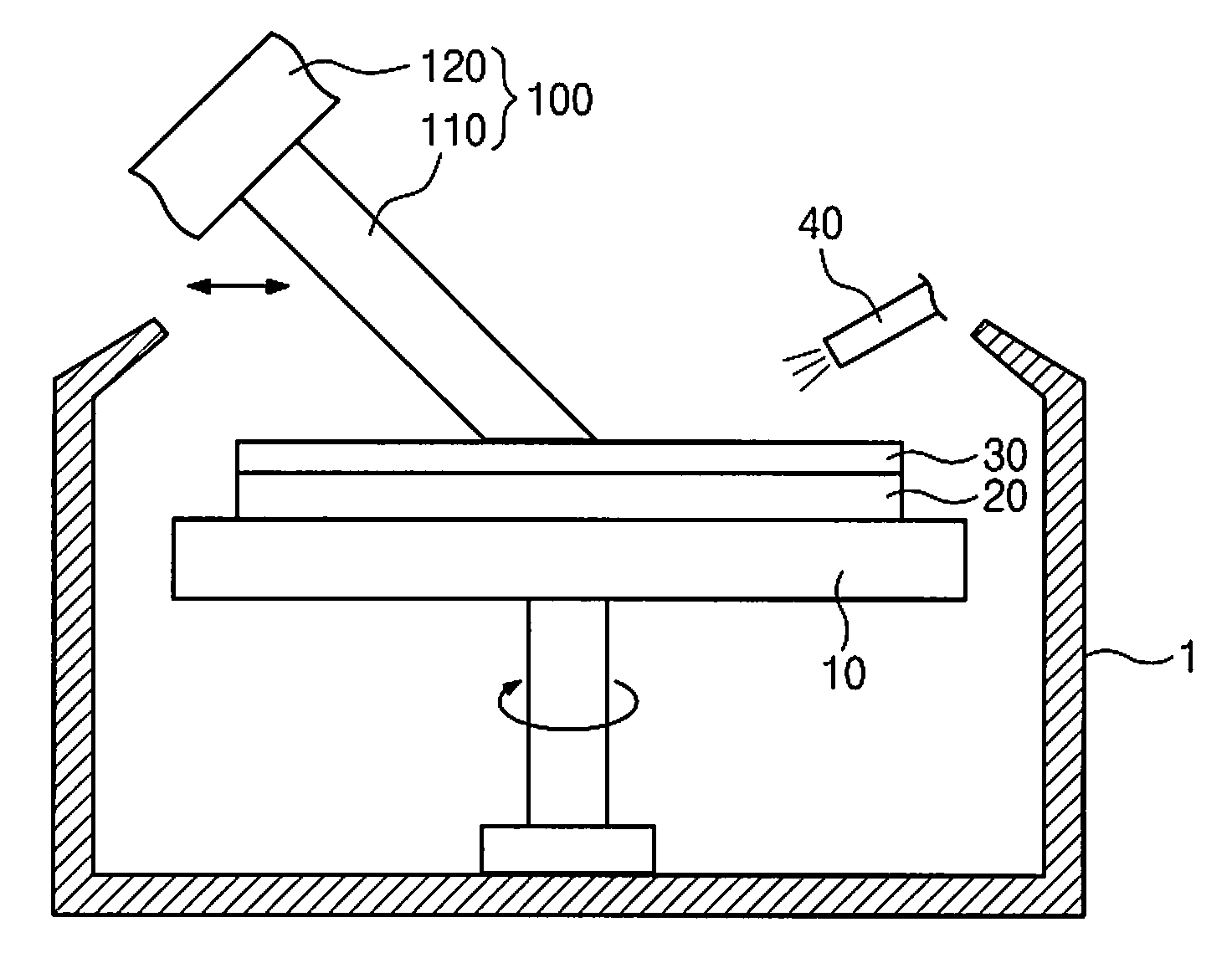

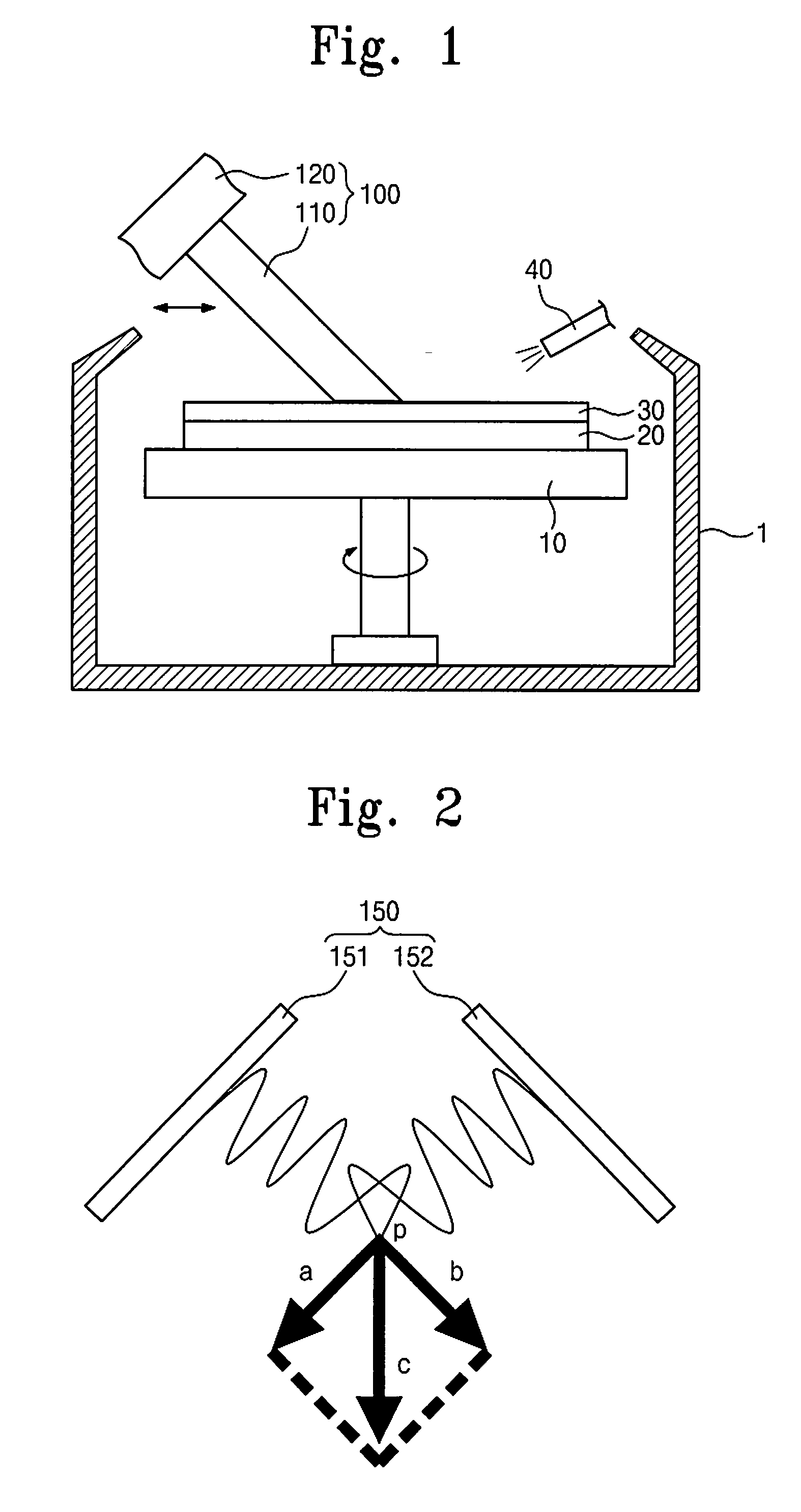

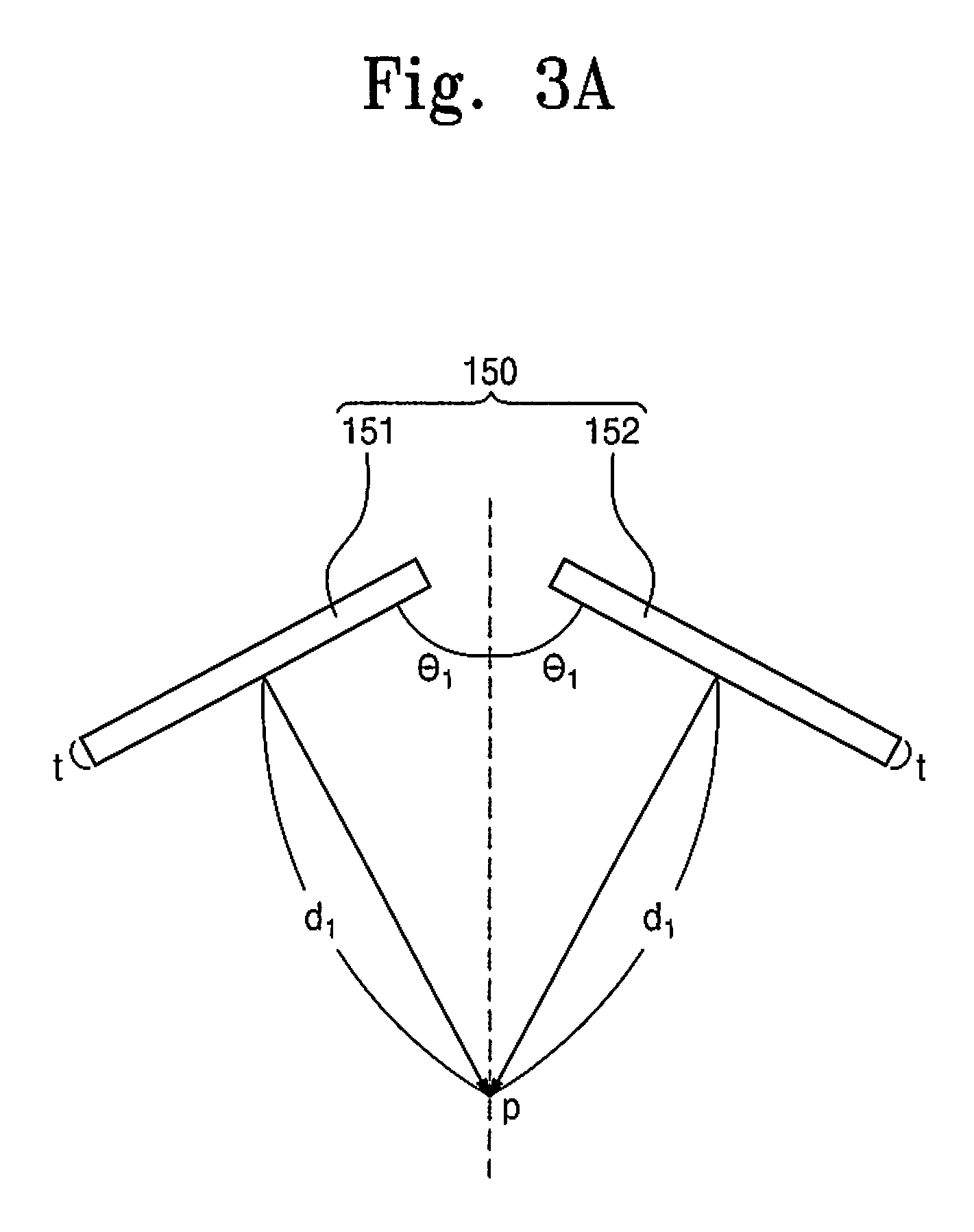

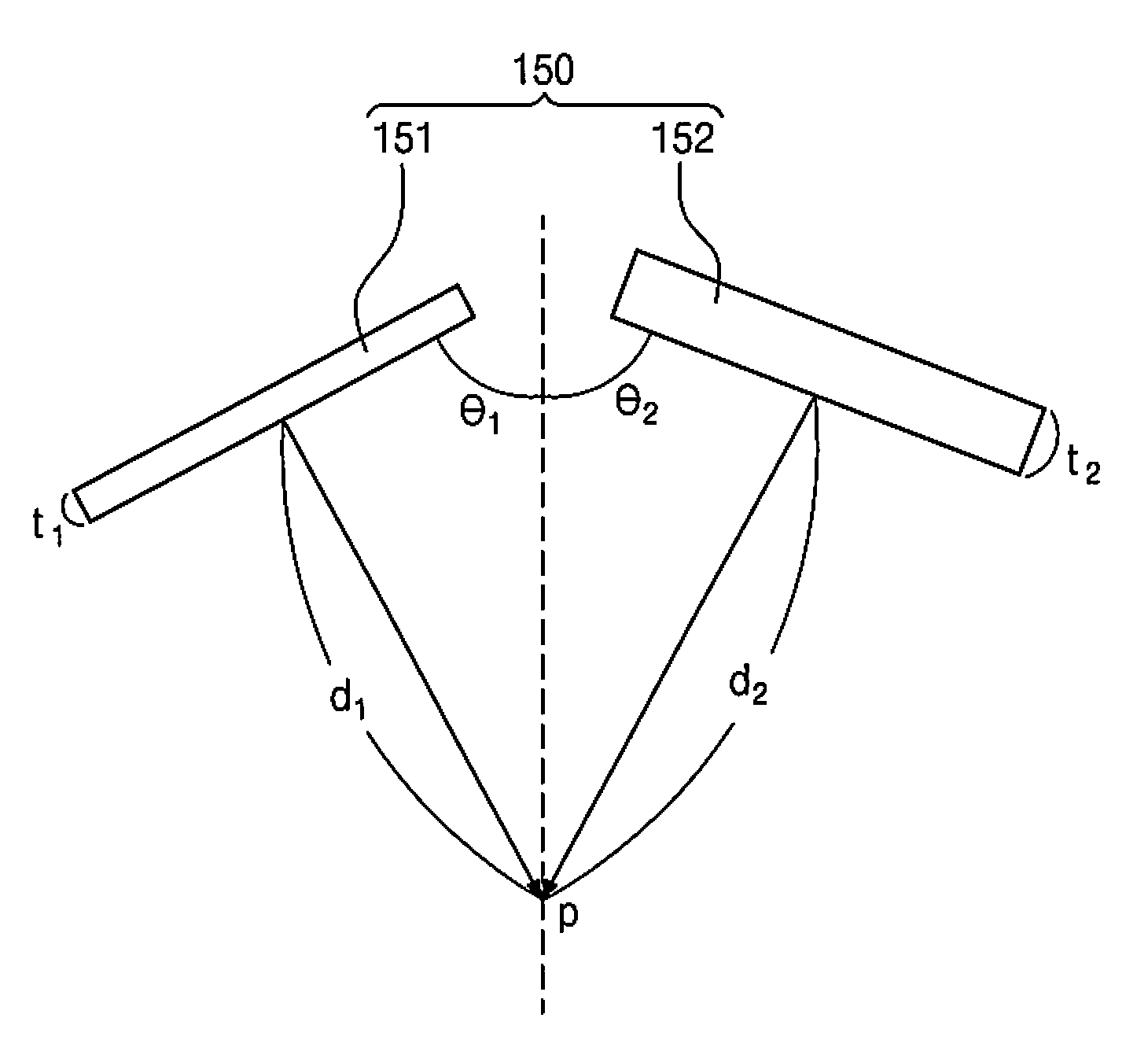

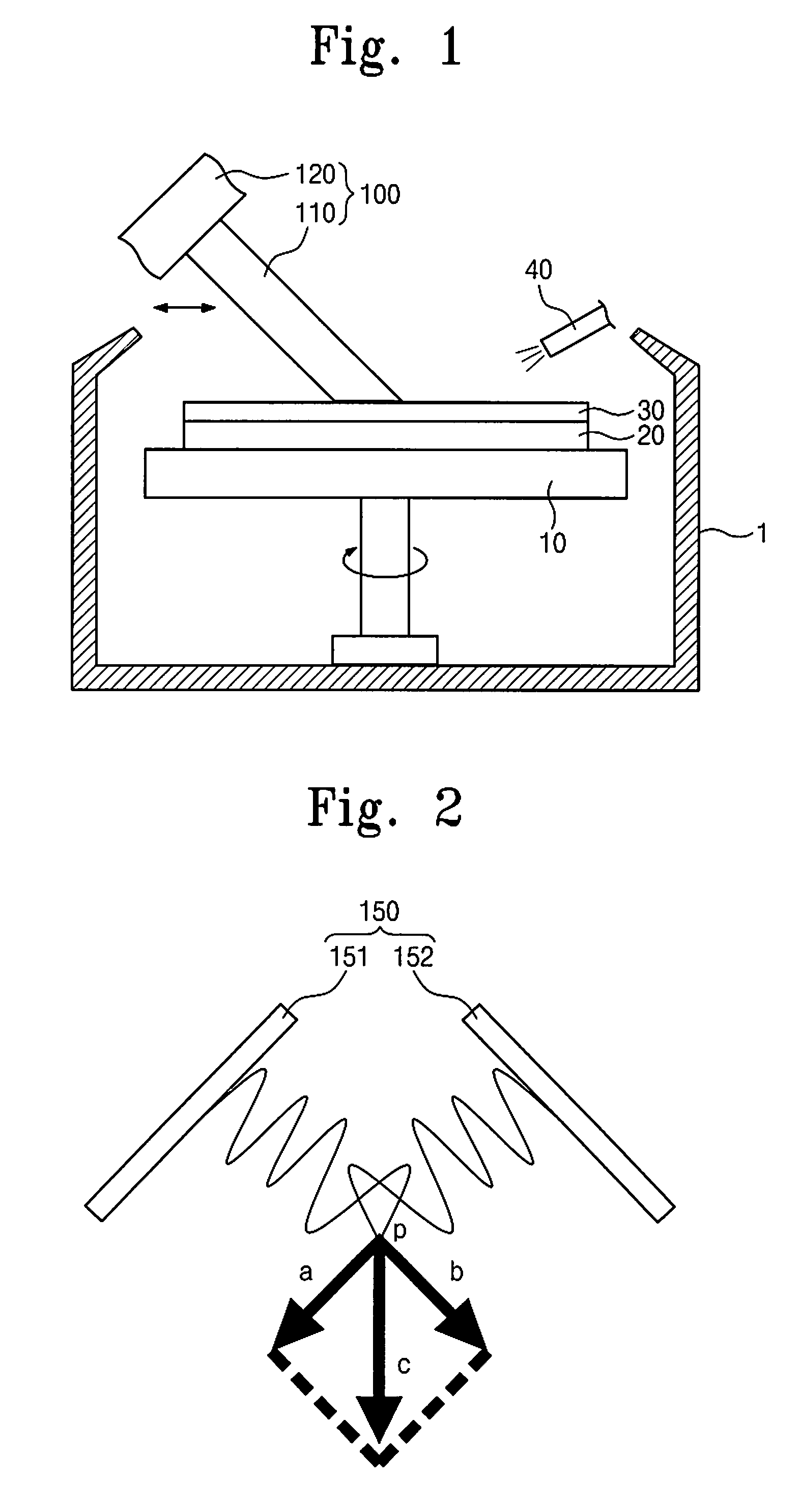

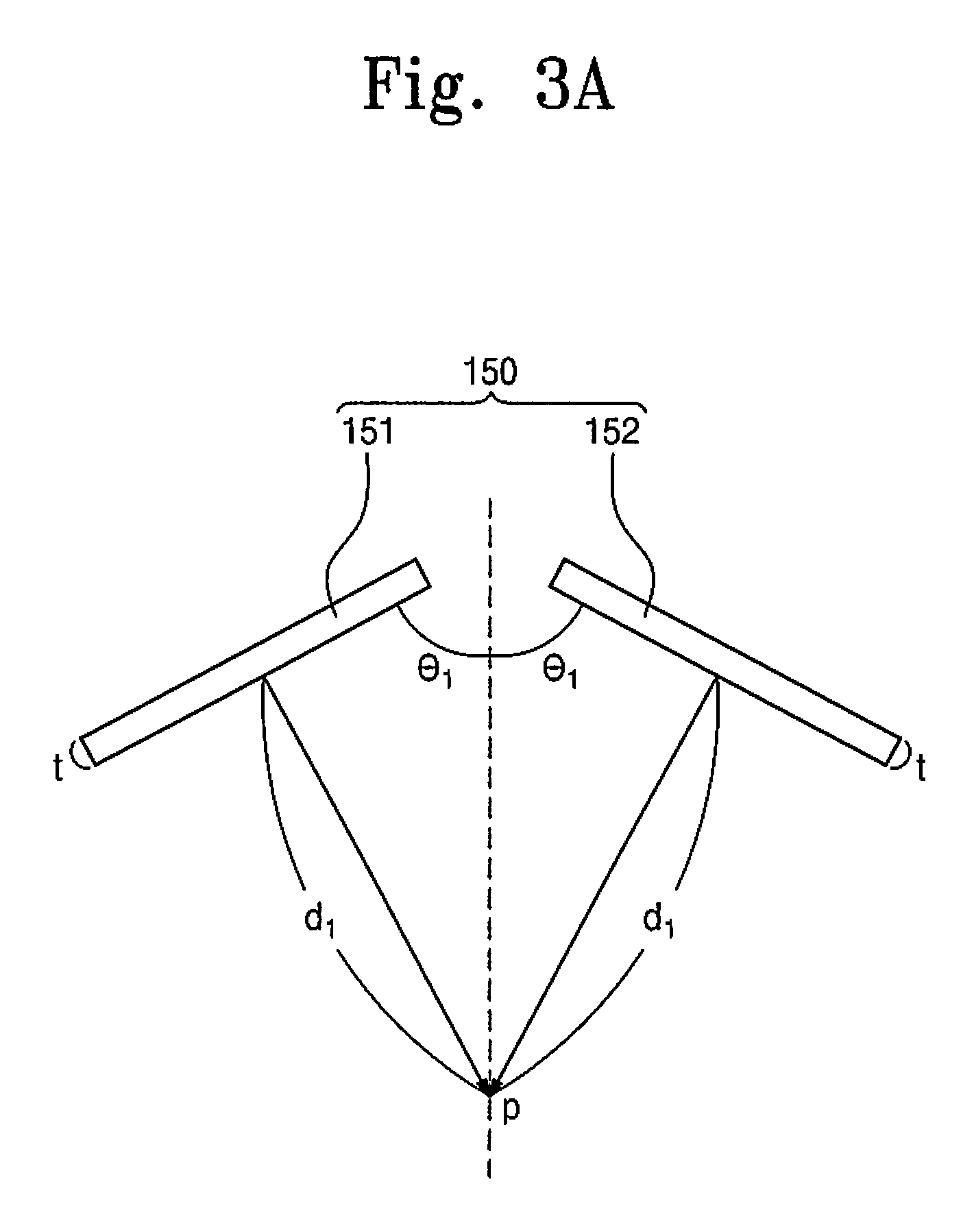

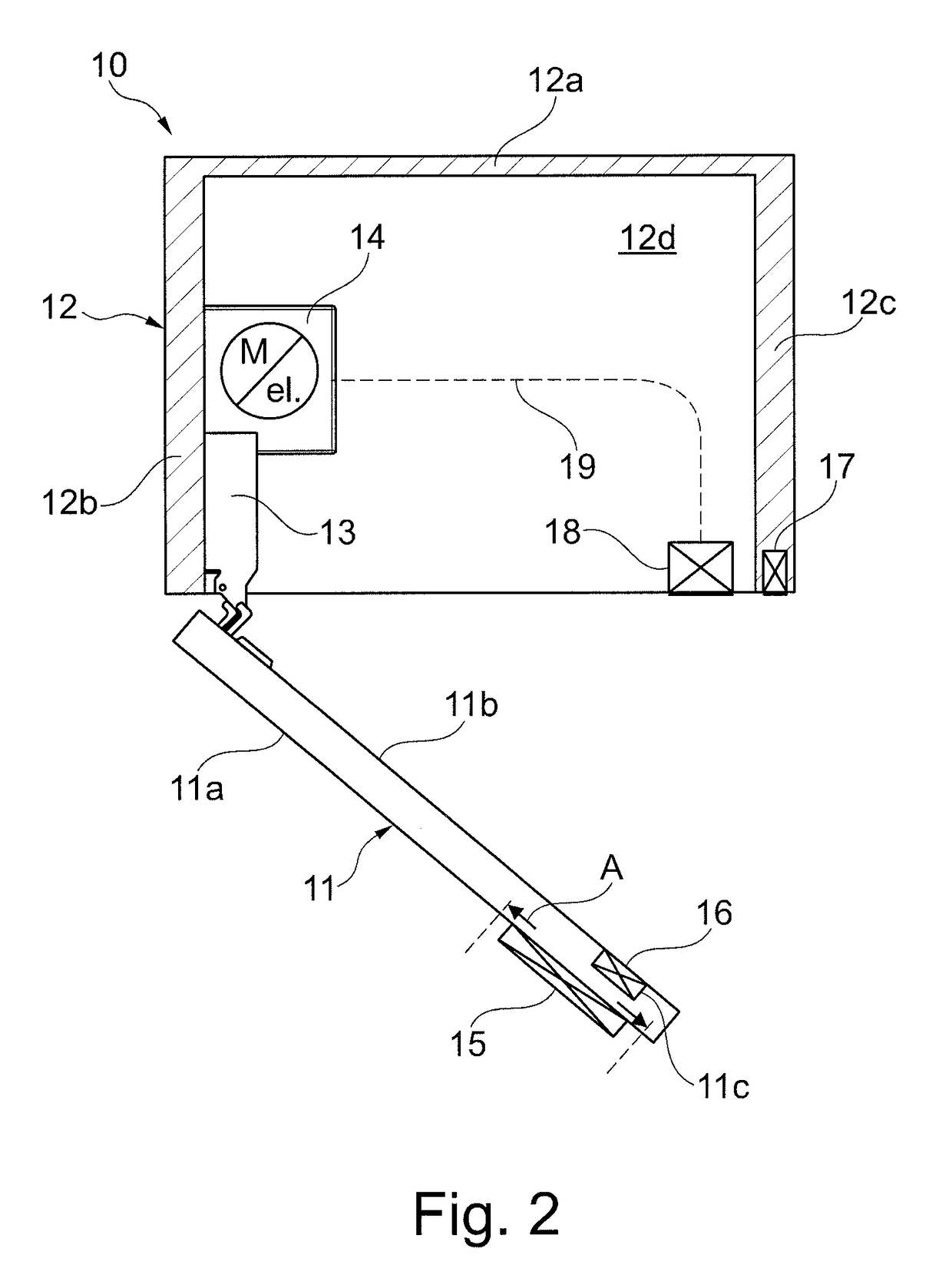

Apparatus for cleaning substrate and method for cleaning substrate

ActiveUS20090050173A1Easy to cleanEquipment efficientSemiconductor/solid-state device manufacturingElectrostatic cleaningEngineeringAcoustic wave

Provided is an apparatus for cleaning a substrate. The apparatus includes a stage on which a substrate is loaded, a cleaning liquid supply unit supplying a cleaning liquid to the substrate, an oscillator transmitting sound waves to the substrate for cleaning the substrate, and at least two piezoelectric members disposed on an end portion of the oscillator at a predetermined distance apart from each other so as to generate the sound waves.

Owner:SEMES CO LTD

Apparatus for cleaning substrate and method for cleaning substrate

ActiveUS8015986B2Equipment efficientSemiconductor/solid-state device manufacturingElectrostatic cleaningEngineeringAcoustic wave

Provided is an apparatus for cleaning a substrate. The apparatus includes a stage on which a substrate is loaded, a cleaning liquid supply unit supplying a cleaning liquid to the substrate, an oscillator transmitting sound waves to the substrate for cleaning the substrate, and at least two piezoelectric members disposed on an end portion of the oscillator at a predetermined distance apart from each other so as to generate the sound waves.

Owner:SEMES CO LTD

Method for manufacturing a sensor for a part of a piece of furniture

ActiveUS20170172302A1Efficiently provideEfficient preparationElectronic switchingPower-operated mechanismIndustrial engineering

Owner:GRASS GMBH & CO KG

Honeycomb core with hierarchical cellular structure

ActiveUS11267212B2Low densityProcess economyPaper/cardboard articlesHollow wall articlesStructural engineeringMechanical engineering

A hierarchical sandwich core in the form of a honeycomb, i.e. having repetitive and periodic lattice materials. The sandwich core can be made up of a macroscopic honeycomb structure with sandwich cell walls having a mesoscopic cellular core. The longitudinal axis of cells of the mesoscopic honeycomb cell can be perpendicular to the longitudinal axis of the cells of the macroscopic honeycomb structure. Alternatively, if a foam core is used having mesoscopic cells the shape of the mesoscopic cells can be made during the foaming process so that they are elongate in a direction perpendicular to the longitudinal axis of the cells of the macroscopic honeycomb structure.

Owner:ECONCORE NV

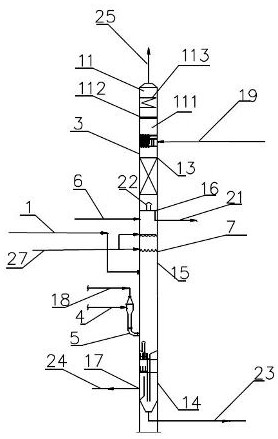

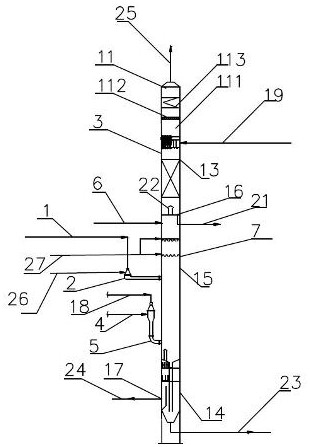

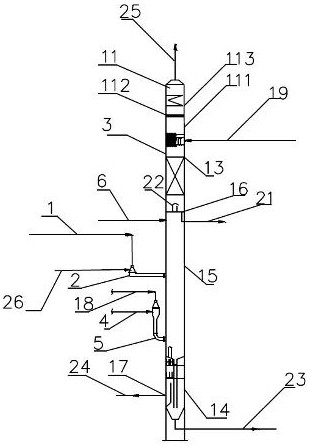

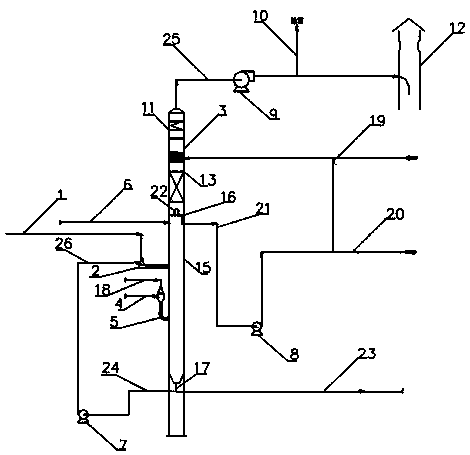

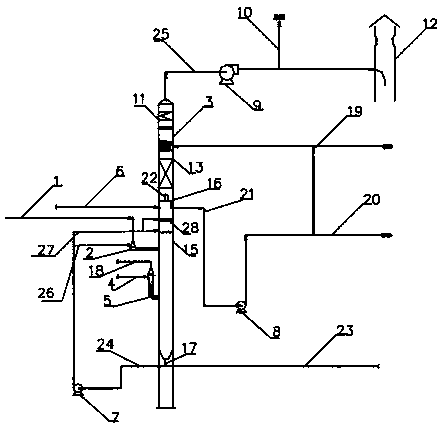

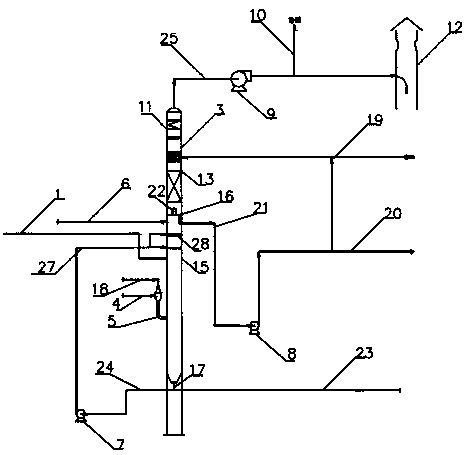

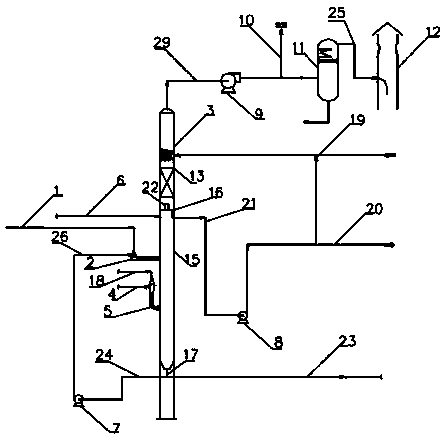

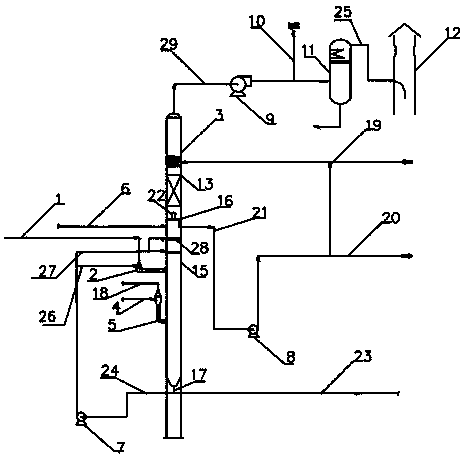

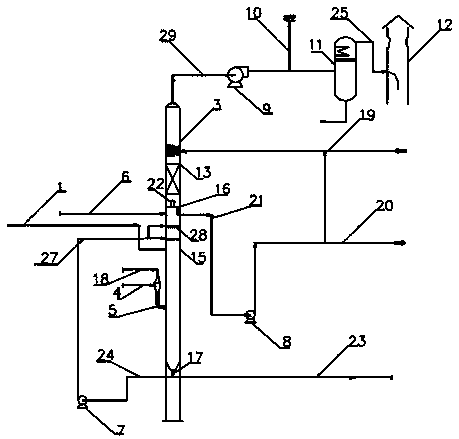

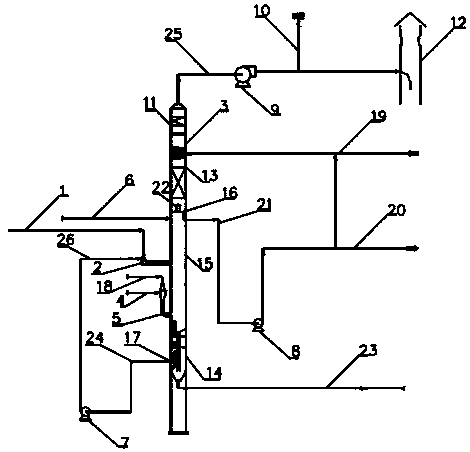

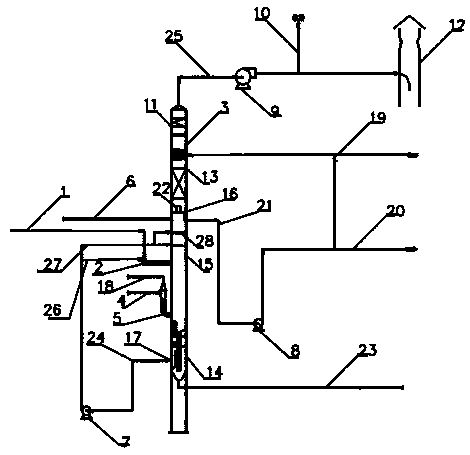

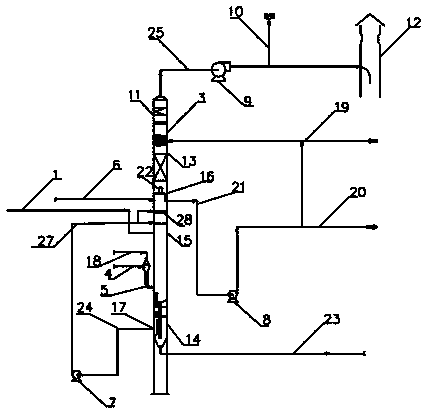

A coking tail gas treatment device

The invention discloses a coking tail gas treatment device to solve the problems of water vapor, malodorous gas pollution, secondary pollution caused by the discharge of tail gas VOC and coke powder along with the tail gas in the existing delayed coking device. The coking tail gas treatment device includes a tail gas treatment tower. The tail gas treatment tower is sequentially composed of a desaturation section, a desulfurization section, a gas-liquid separation section and a settling section from top to bottom. A desulfurization section oil collecting tank is arranged below the desulfurization section in the tail gas treatment tower. Below the gas-liquid separation section, there are coke tower tail gas and other equipment in the coking unit to generate tail gas injection pipeline, coke tank tail gas injection pipeline, coke tower discharge steam injection pipeline, and the bottom of the tail gas treatment tower is provided with washing sewage extraction pipeline The lower part of the settling section is provided with a washing water extraction bucket, the upper part of the desulfurization section is provided with an absorbing liquid injection line, the lower part of the desulfurization section oil collection tank is provided with a desulfurization section oil collection tank extraction outlet, and the top of the tail gas treatment tower is provided with a desaturated coking tail gas pipeline.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for manufacturing a sensor for a part of a piece of furniture

ActiveUS10681981B2Efficiently provideEfficient preparationElectronic switchingPower-operated mechanismMechanical engineeringManufacturing engineering

Owner:GRASS GMBH & CO KG

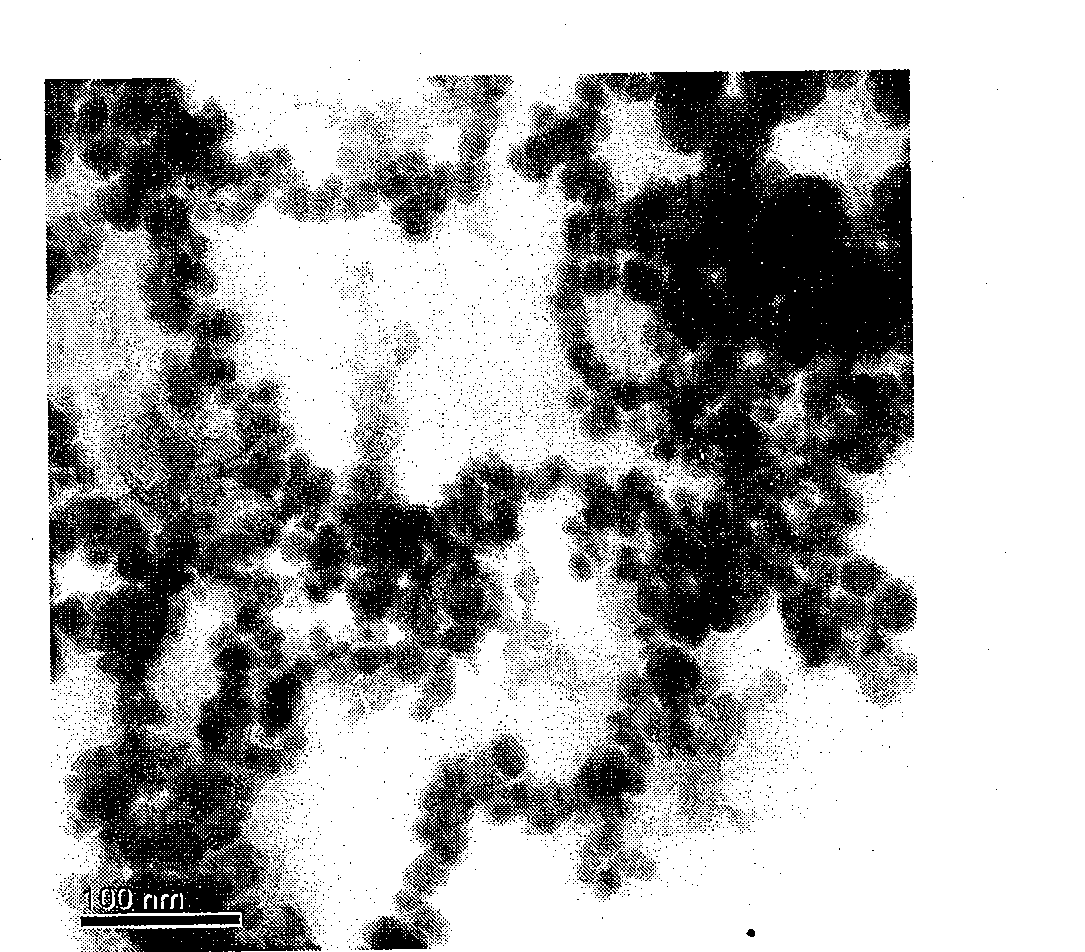

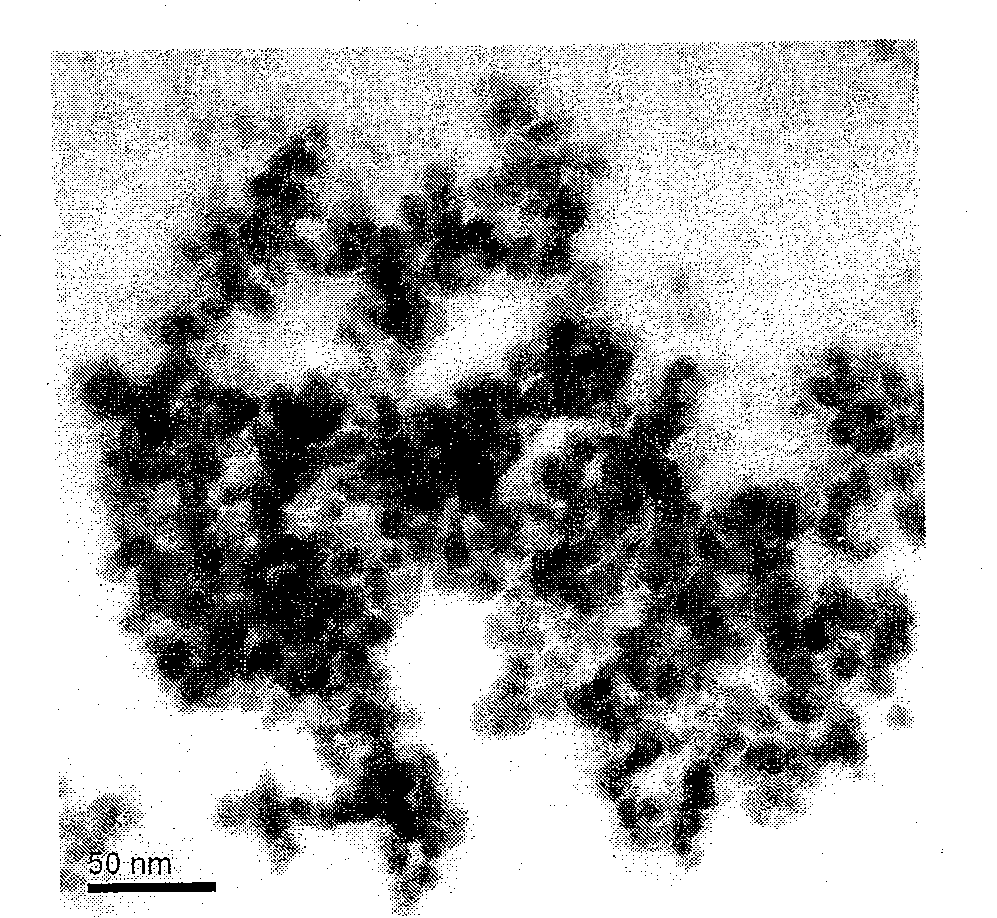

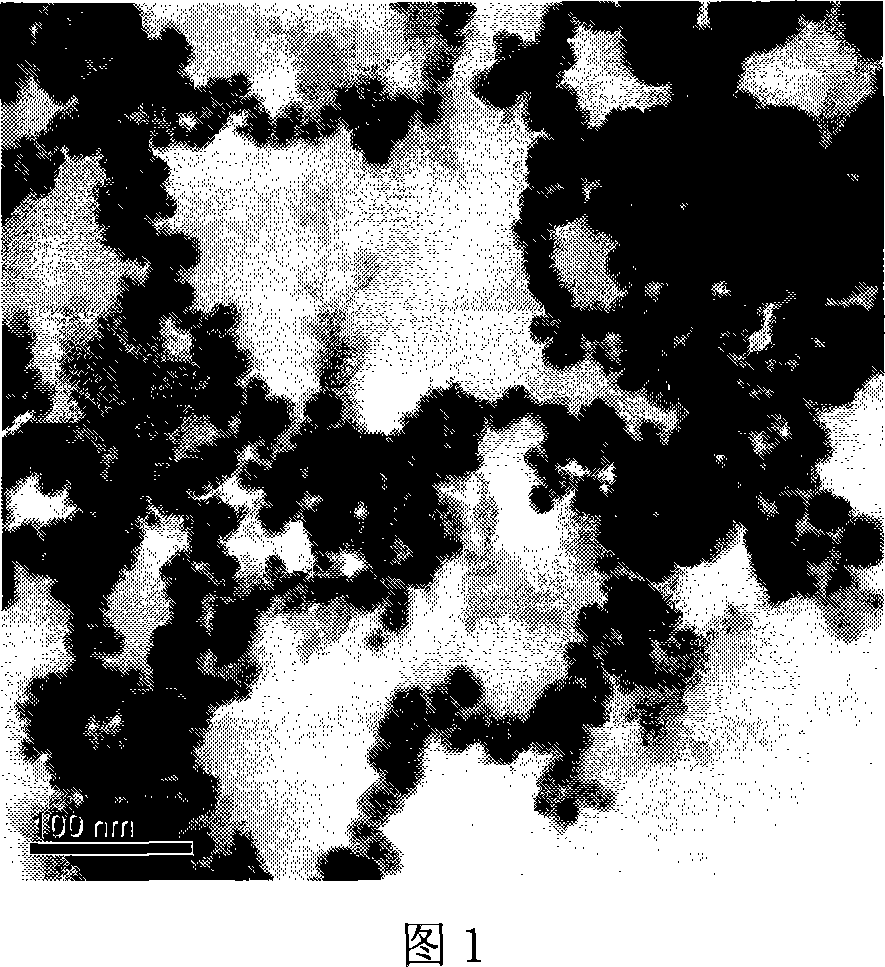

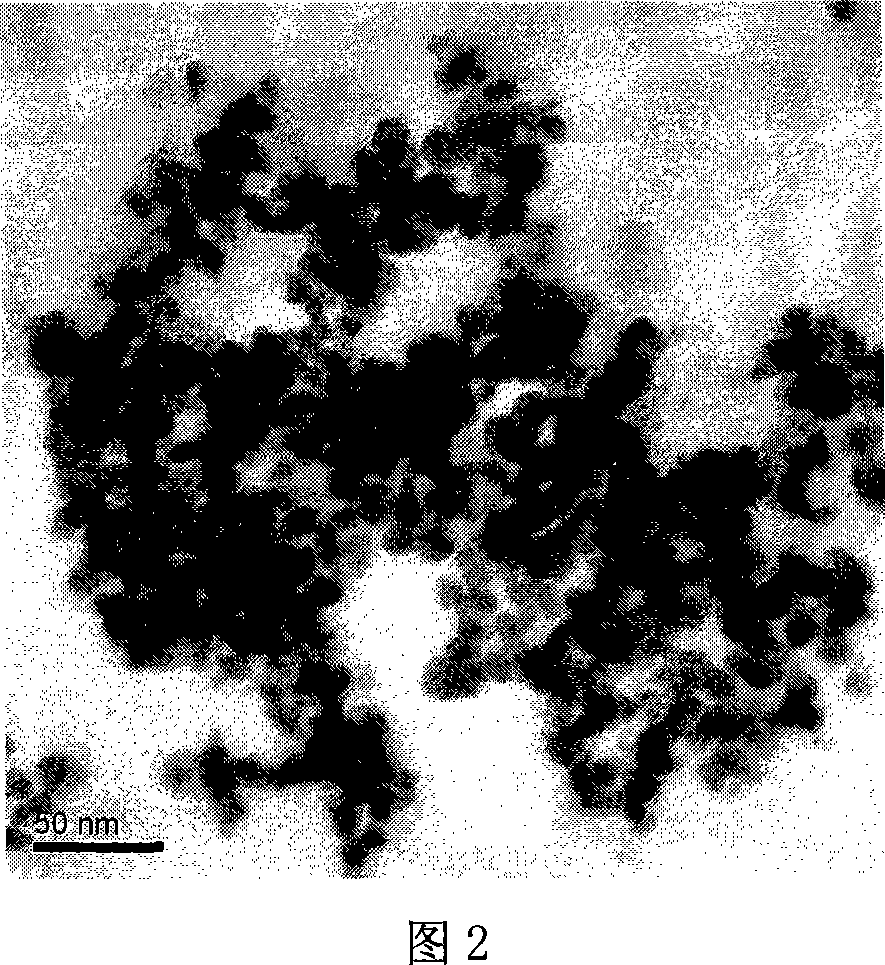

Method for preparing ferrum series non-crystalline state nanometer simple substance

The invention belongs to inorganic nanometer material field, especially relates to a method for preparing a ferrious noncrystalline nanometer simple substance, comprising the following steps: weighing two solids of A and B, respectively preparing solution B and solution A having concentration of 0.1-0.4mol / L, the mol concentration ratio of solution A and solution B is 1:1; adding deionized water in solution A, implementing ultrasonic concussion to generate mass air bubbles in the solution and when the air bubbles disappear, stopping the ultrasonic concussion and the reaction, then adding with the solution B to react in a centrifugal machine, wherein the reaction time is 2 -5 minutes, and finally getting black sediments, after washing to obtain the required product. The solid A is KBH4 powder, solid B is any one of FeCl2(or FeCl3), NiCl2.6H2O or CoCl2.6H2O etc. The solution A is KBH4 water solution, the solution B is any one of FeCl2( or FeCl3) ethanol solution, NiCl2 ethanol solution or CoCl2 ethanol solution etc. The invention has advantages of easily obtaining raw material, low cost and simple operation and equipment, small and even grain size of the product, is easy to industrialize, and can provide new approach and way for the synthesis of nanometer material.

Owner:TONGJI UNIV

Coking tail gas treatment method and coking tail gas treatment device

ActiveCN111068494ASolve secondary pollutionFix the leakCombination devicesGas treatmentCokeSolid particle

The invention discloses a coking tail gas treatment method and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the coke pool and the coke powder of the existing delayed coking device. According to the device, cokepool tail gas, coke tower discharge steam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas continuously rises to reach a desaturation section; after desaturation, the tail gas is discharged from the top ofthe tail gas treatment tower, VOC is removed, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section;after failure, the waste liquid is externally sent to a treatment unit; and the washing water containing solid particles in the tail gas treatment tower enters a settling section downwards, the washing sewage containing solid particles comes out from the bottom of the tail gas treatment tower, and the clarified washing water comes out from a washing water pumping hopper at the lower portion of thetail gas treatment tower and is pressurized so as to be recycled as circulating washing water.comes out from the top of the tail gas treatment tower, VOC is removed, and then the tail gas is emptied;the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section; after failure, the waste liquid is sent to a treatment unit; and the washing water in the tail gas treatment tower flows out downwards from the bottom of the tail gas treatment tower, one part is discharged out of the device, and the other part is pressurized and then recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

Back-Contacted Photovoltaic Device

InactiveUS20100132781A1Improve efficiencyIncreases useful surface areaPhotovoltaic energy generationSemiconductor devicesSemiconductor materialsEngineering

A new photovoltaic device includes at least one front emitter made of a p- or n-doped semiconductor material, coupled with at least one rear part made of an n- or p-doped semiconductor material, wherein the front part of the emitter is connected to a plurality of contacts located at the back of the device by means of one or more diffuser elements in the shape of plates, ducts or generic elements in relief made of p- or n-doped semiconductor material, which extend from the front part of the emitter through all or part of the n- or p-doped part.

Owner:XGROUP

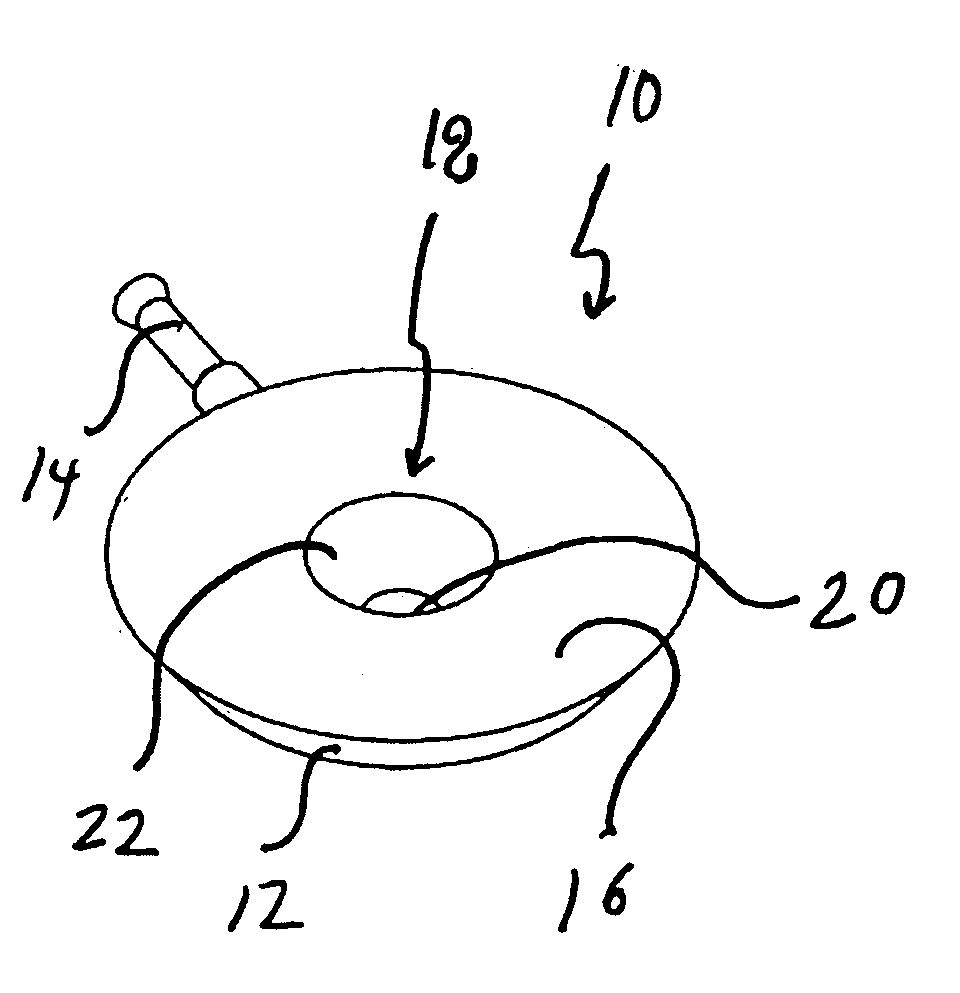

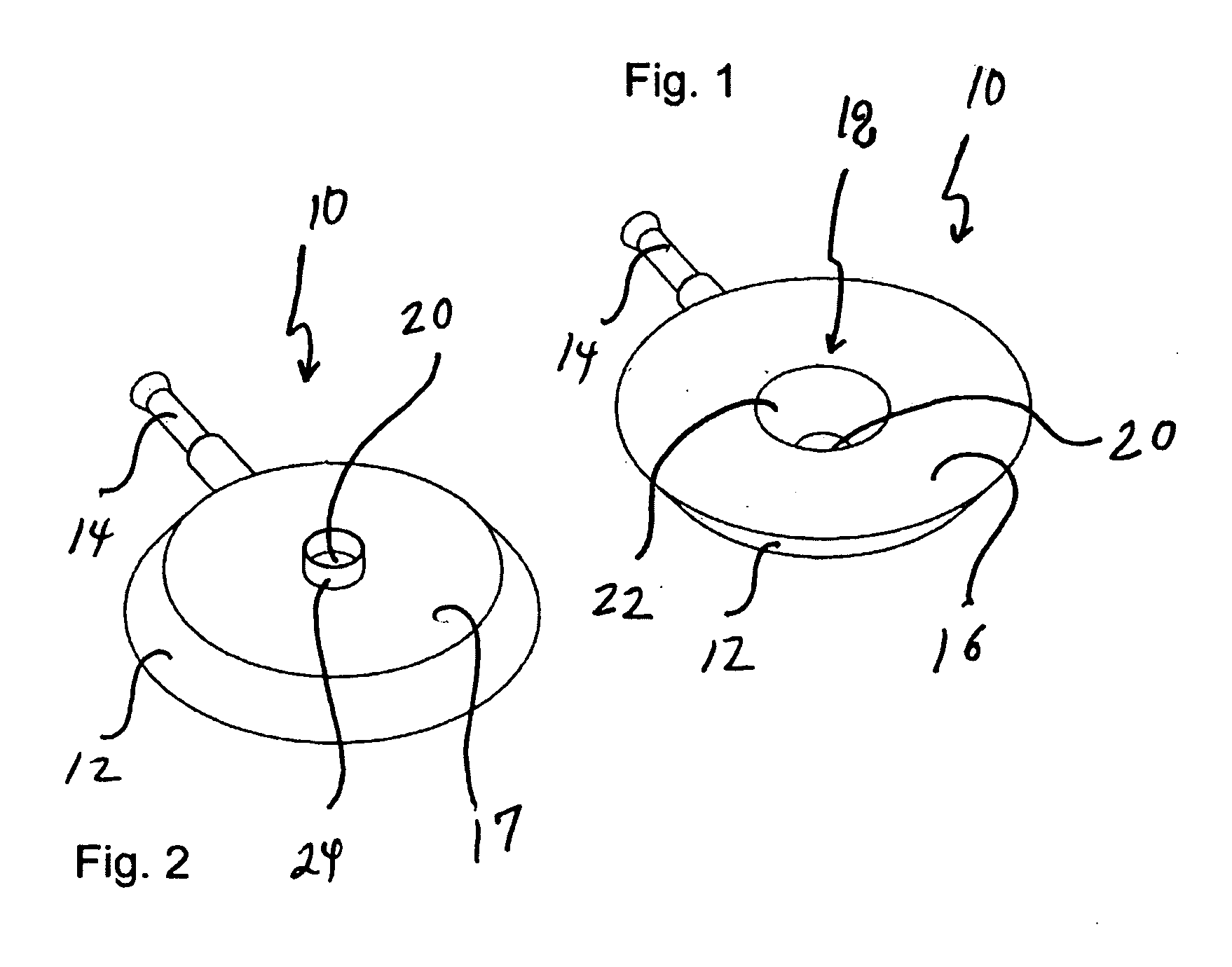

Infrared burner with exhaust gas flue

InactiveUS20080149091A1Equipment efficientDomestic stoves or rangesStoves/ranges topsFlueExhaust gas

An infrared range burner having a plurality of gas passageways formed therein for delivering combustion gas from a central gas supply to individual burner jets, the range burner including a burner body formed as a closed loop defining an open central area, the burner body having a plurality of gas passageways formed therein; a burner top disposed on the burner body and including burner jets in communication with the gas passageways;a burner bottom having an exhaust opening formed in a central area thereof, the burner bottom being disposed on the burner body oppositely from the burner top, with the open central area in registry with the exhaust opening and extending between the burner top and the burner bottom; and a flue mounted to the burner bottom and projecting outwardly therefrom, the flue being in fluid communication with the exhaust opening for drawing exhaust gases from the open central area.

Owner:BSH HOME APPLIANCES CORP

Coking tail gas treatment process and coking tail gas treatment device

ActiveCN111068493ASolve secondary pollutionFix the leakCombination devicesGas treatmentCokeWater circulation

The invention discloses a coking tail gas treatment process and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the existing delayed coking device. According to the device, coke pool tail gas, coke tower dischargesteam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas is discharged from the top of the tail gas treatment tower, enters a desaturator and is desaturated; the desaturated coking tail gas is discharged fromthe desaturator, VOC is removed, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and then returned to the upper portion of the desulfurization section; after failure, the waste liquid is externally sent out to a treatment unit and is treated; and the washing water in the tail gas treatment tower flows out downwards from the bottom of the tail gas treatmenttower, one part is discharged out of the device, and the other part is pressurized and then recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

Coking tail gas treatment process and coking tail gas treatment device

The invention discloses a coking tail gas treatment process and a coking tail gas treatment device. A purpose of the invention is to solve the problems of secondary pollution and the like caused by vapor and malodorous gas pollution and tail gas VOC and coke powder discharge along with tail gas of the existing delayed coking device. According to the device, coke pool tail gas, coke tower dischargesteam, coke tower tail gas and tail gas generated by other equipment in a coking device enter the gas-liquid separation section of a tail gas treatment tower and are subjected to gas-liquid separation; the gas-phase coking tail gas rises to a desulfurization section and is in countercurrent contact with an absorption liquid entering from the upper portion of the desulfurization section so as to be desulfurized; the desulfurized coking tail gas continuously rises to reach a desaturation section; after desaturation, the tail gas is discharged from the top of the tail gas treatment tower, VOC isremoved, and then the tail gas is emptied; the rich absorption liquid is pumped out, pressurized and returned to the upper portion of the desulfurization section; after failure, the waste liquid is externally sent to a treatment unit; and the washing water containing solid particles in the tail gas treatment tower enters a settling section downwards, the washing sewage containing solid particlescomes out from the bottom of the tail gas treatment tower, and the clarified washing water comes out from a washing water pumping hopper at the lower portion of the tail gas treatment tower and is pressurized so as to be recycled as circulating washing water.

Owner:CHINA PETROLEUM & CHEM CORP +2

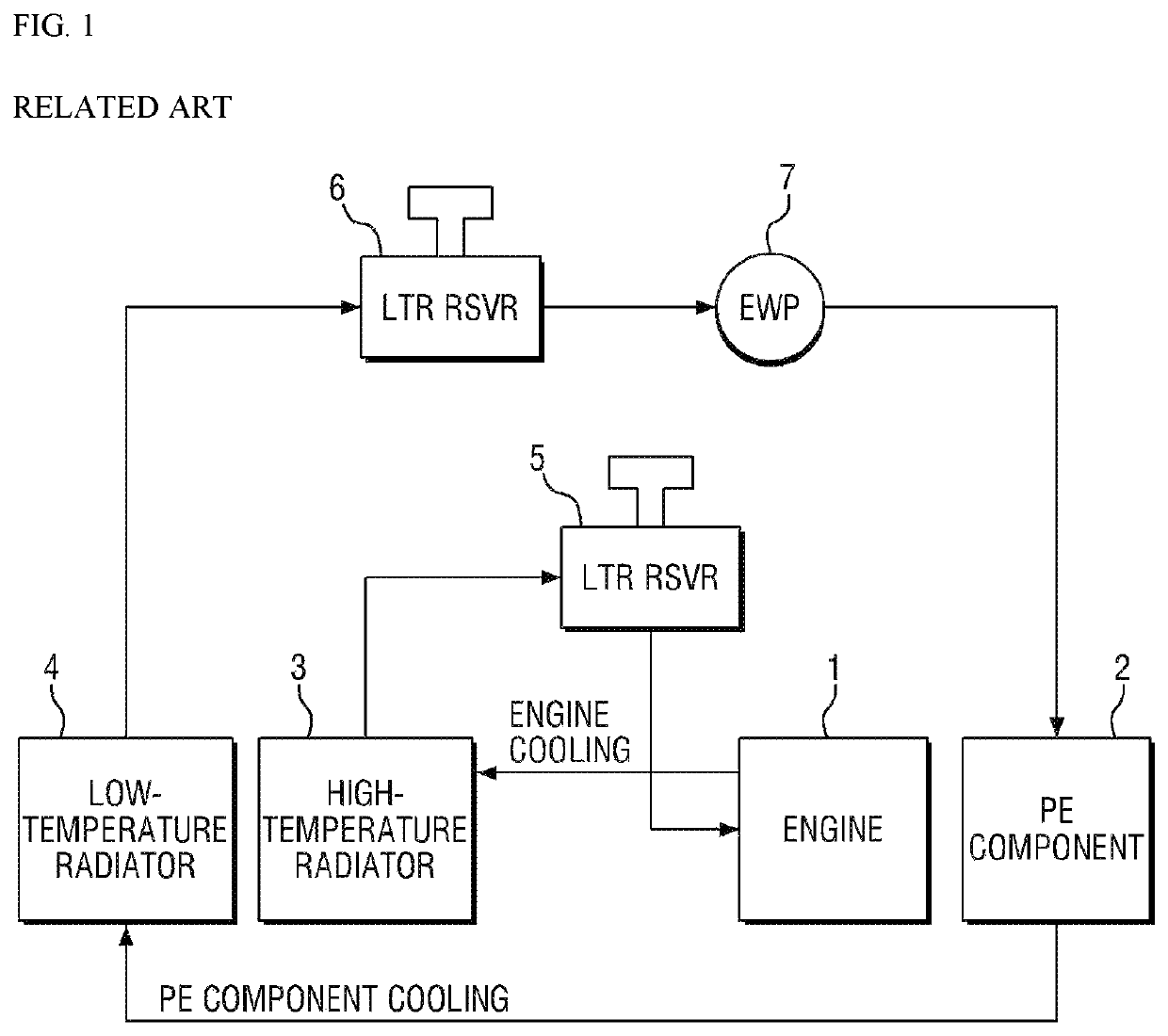

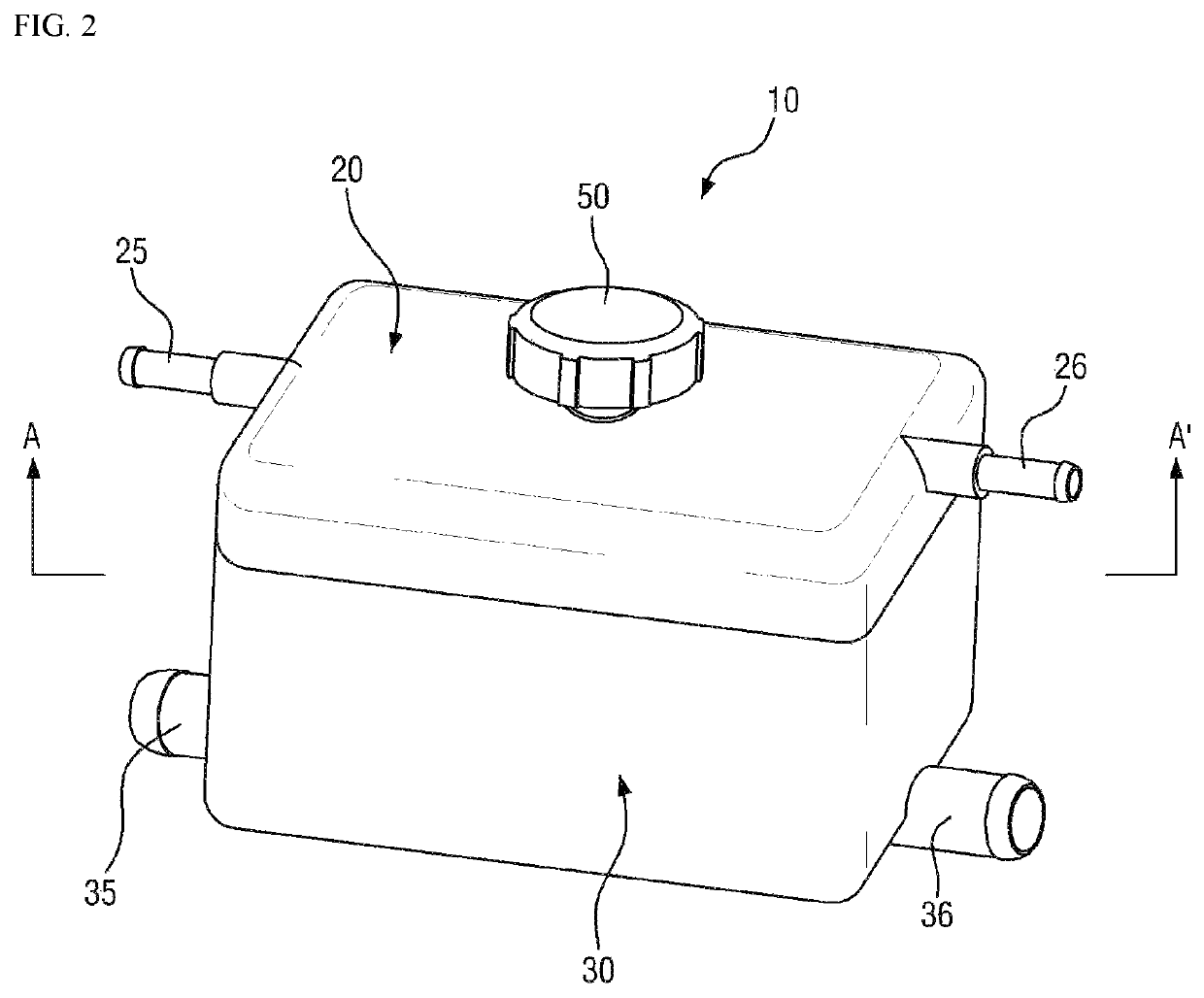

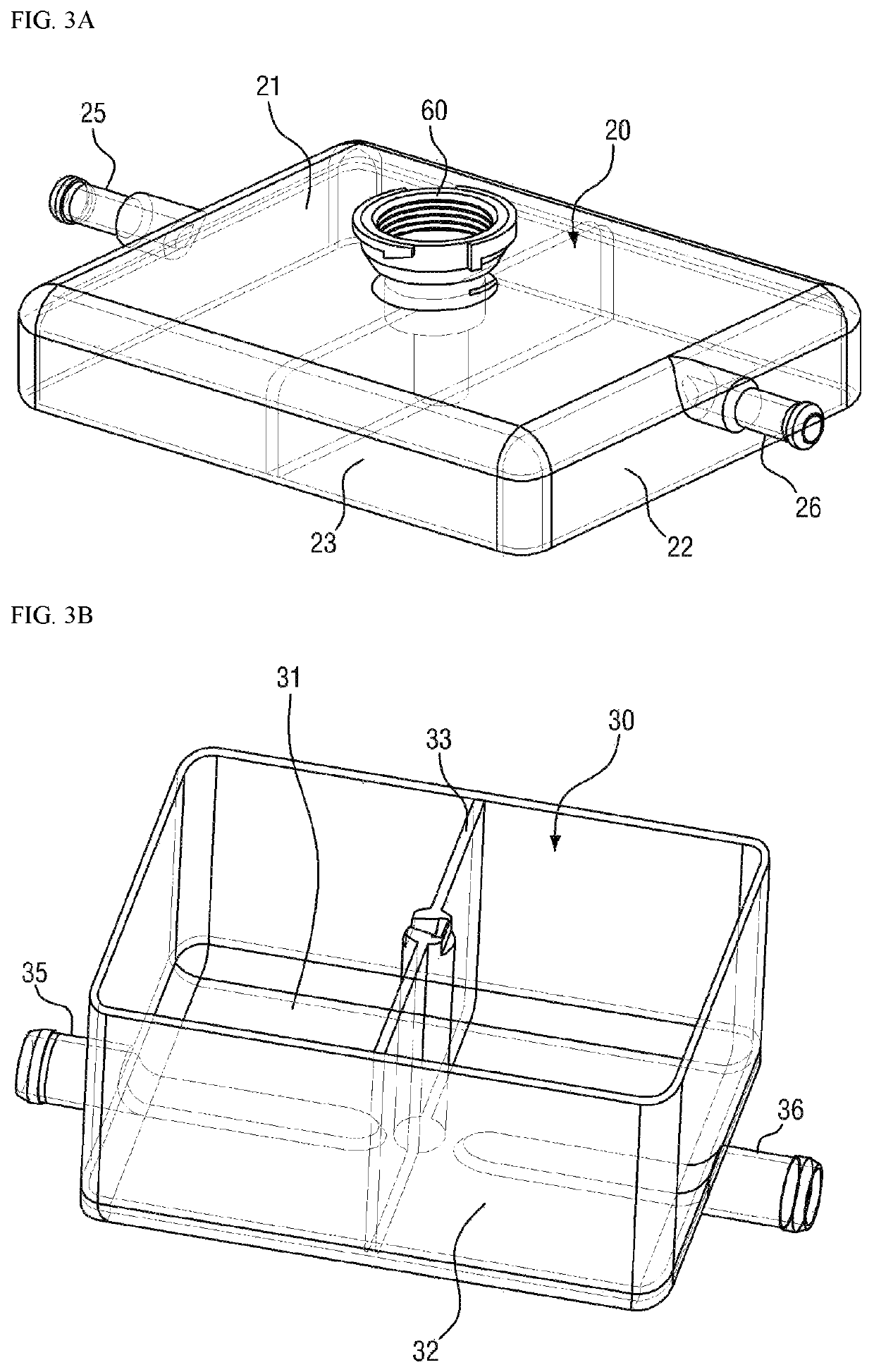

Integrated type reservoir for vehicle

ActiveUS11319865B2Efficiently packageManufacturing cost be reduceLiquid coolingCoolant flow controlEngineeringLiquid storage tank

A reservoir for a vehicle is provided. The reservoir is accommodated in a body formed by joining an upper case and a lower case to each other. A high-pressure reservoir space introduces and discharges coolant flowing from a high pressure cooling line and a low-pressure reservoir space introduces and discharges coolant flowing from a low pressure cooling line. A valve is also installed to maintain internal pressure of the high-pressure reservoir space and the low-pressure reservoir space constant.

Owner:HYUNDAI MOTOR CO LTD +1

Hierarchical honeycomb core with sandwich cell walls

ActiveUS11192316B2Good load transferLow densityPaper/cardboard articlesSynthetic resin layered productsClassical mechanicsCell wall

A hierarchical sandwich core and a method of making it where a macroscopic honeycomb with a first macroscopic cell with first sandwich cell walls is connected to neighbouring macroscopic cells with neighbouring sandwich cell walls. The first and neighbouring sandwich cell walls are made of a sandwich material having a width, a mesoscopic core, and a first skin layer on a first major surface and a second skin layer on a second major surface of the sandwich material, both skin layers being attached to the mesoscopic core forming each sandwich cell wall of the macroscopic honeycomb. The first and the neighbouring cell walls have a height determined by the width of the sandwich material, both skin layers of the first sandwich cell wall being connected to both skin layers of at least one neighbouring cell wall along the height of the first cell wall.

Owner:ECONCORE NV

Method for preparing ferrum series non-crystalline state nanometer simple substance

The invention belongs to inorganic nanometer material field, especially relates to a method for preparing a ferrious noncrystalline nanometer simple substance, comprising the following steps: weighing two solids of A and B, respectively preparing solution B and solution A having concentration of 0.1-0.4mol / L, the mol concentration ratio of solution A and solution B is 1:1; adding deionized water in solution A, implementing ultrasonic concussion to generate mass air bubbles in the solution and when the air bubbles disappear, stopping the ultrasonic concussion and the reaction, then adding with the solution B to react in a centrifugal machine, wherein the reaction time is 2 -5 minutes, and finally getting black sediments, after washing to obtain the required product. The solid A is KBH4 powder, solid B is any one of FeCl2(or FeCl3), NiCl2.6H2O or CoCl2.6H2O etc. The solution A is KBH4 water solution, the solution B is any one of FeCl2( or FeCl3) ethanol solution, NiCl2 ethanol solution or CoCl2 ethanol solution etc. The invention has advantages of easily obtaining raw material, low cost and simple operation and equipment, small and even grain size of the product, is easy to industrialize, and can provide new approach and way for the synthesis of nanometer material.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com