Infrared burner with exhaust gas flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

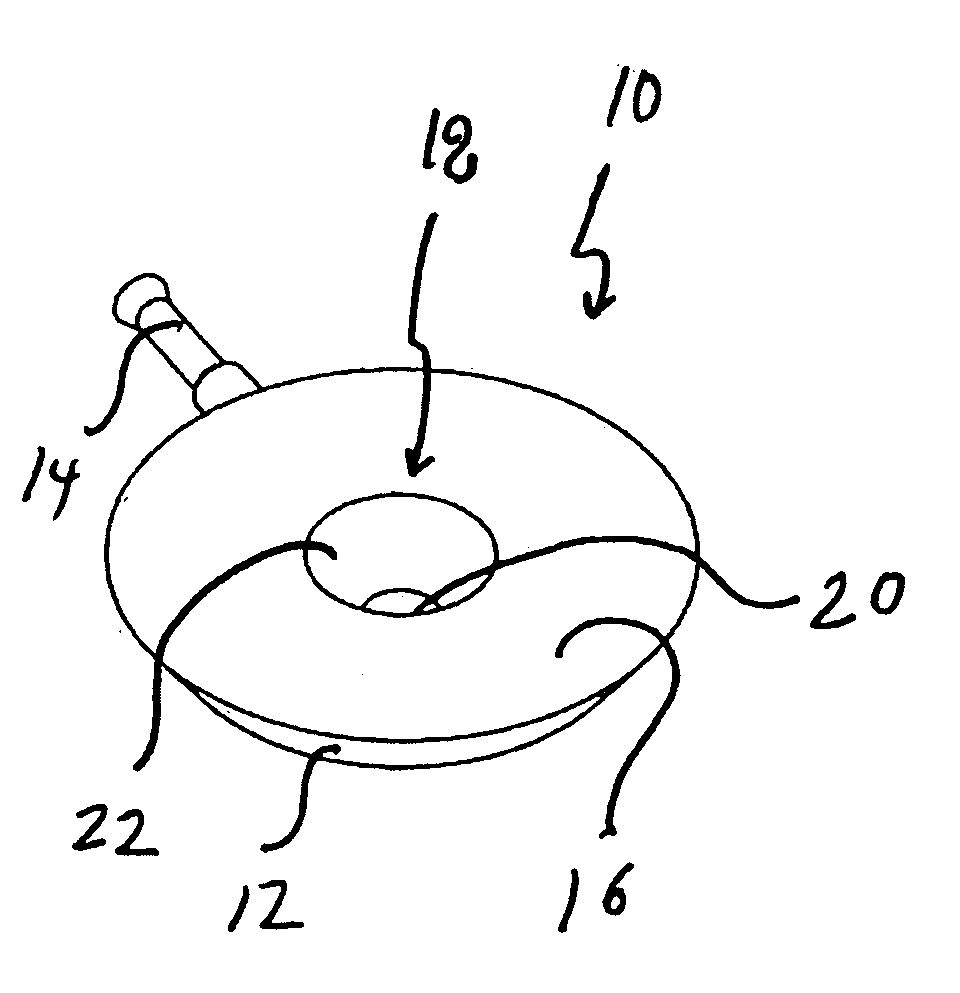

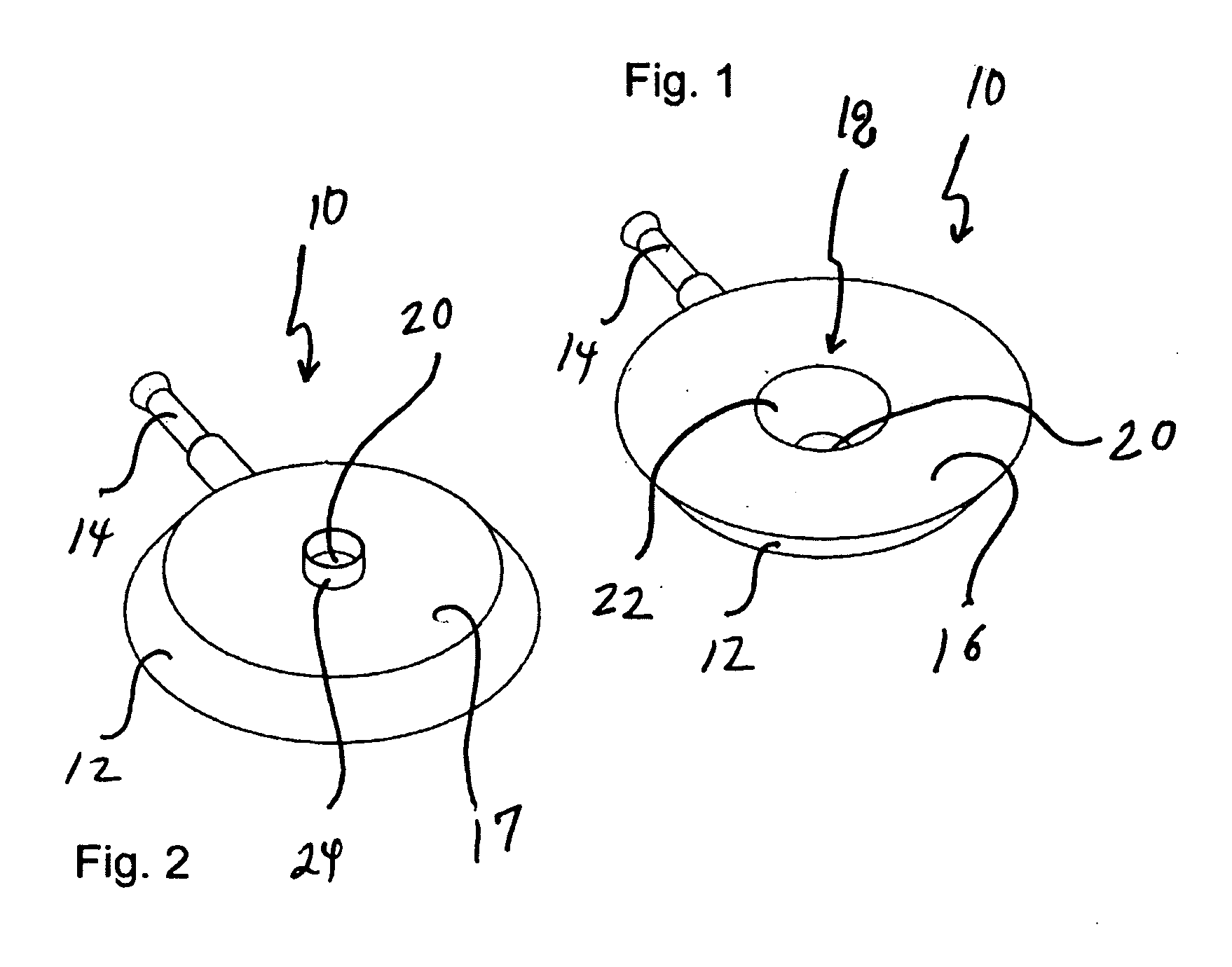

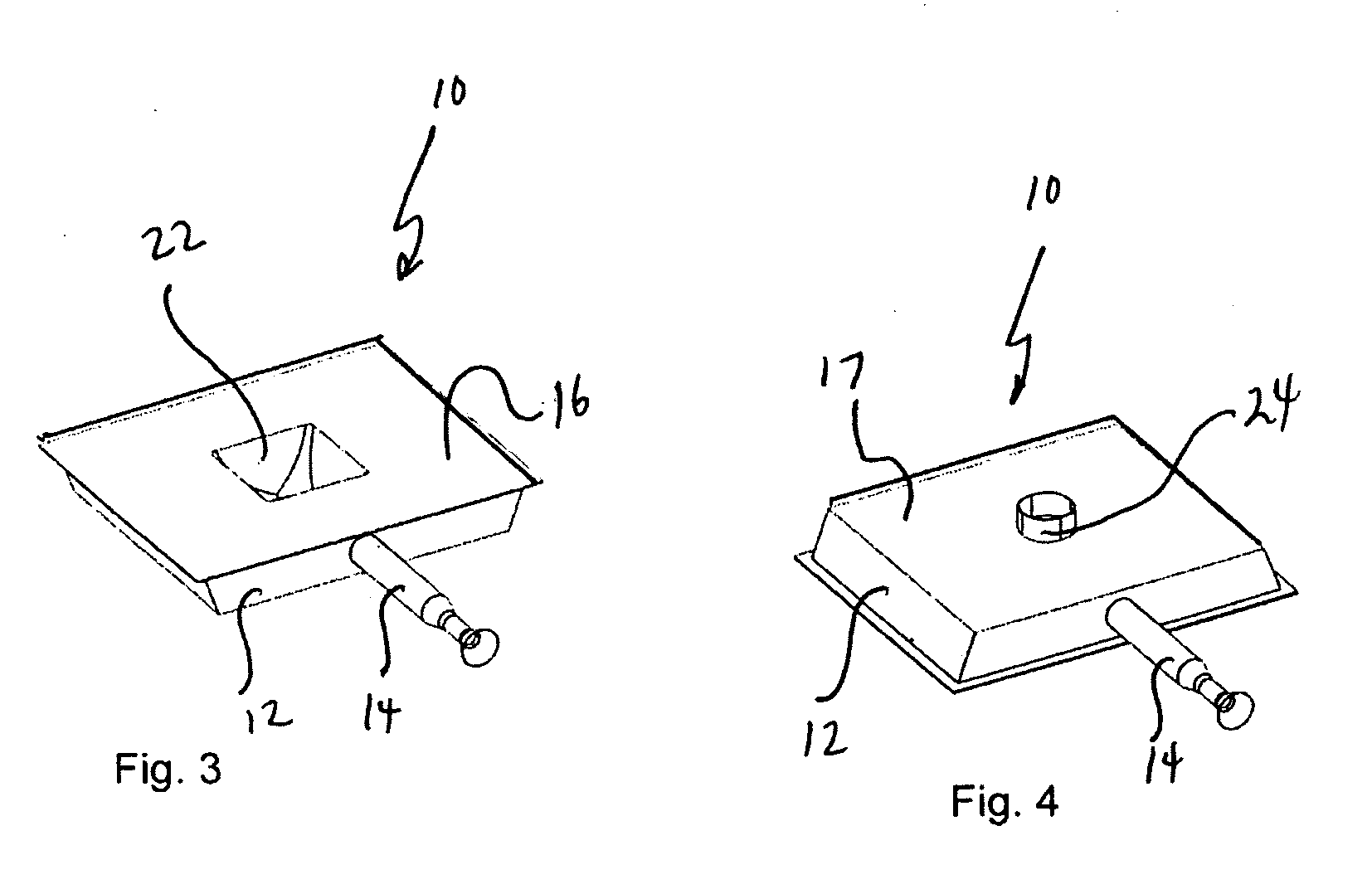

[0010]Turning now to the drawings and, more particularly to FIG. 1, an infrared burner is illustrated generally at 10 and includes a generally circular burner body 12 having a burner top 16 and a burner bottom 17 attached thereto as seen in FIGS. 1 and 2. The result is a washer-like structure with tapered side walls wherein the major and minor diameters of the burner top 16 are larger than the major and minor diameters of the burner bottom 17. A gas feed pipe 14 projects outwardly from one portion of the burner body 12. The burner body 12 defines gas passageways therein (not shown).

[0011]A central area 18 is defined by the central openings within the burner top 16 and burner bottom 17. The opening of the burner bottom 17 is an exhaust opening 20. Walls 22 are formed on the inside of the central area and are tapered from the larger central area opening to the smaller exhaust opening 20. The walls 22 of the central area 18 act like a nozzle and if a draft is drawn through the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com