Method for preparing ferrum series non-crystalline state nanometer simple substance

A nano elemental, amorphous technology, applied in the field of inorganic nanomaterials, can solve the problems of low efficiency, poor uniformity of powder particle size distribution, harsh reaction conditions, etc., and achieve the effect of simple process and equipment, small product particle size and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare FeCl with a molar concentration of 0.1mol / L respectively 2 ethanol solution and KBH 4 Aqueous solution, accurately measure 0.1ml of KBH with a concentration of 0.1mol / L 4 Place the aqueous solution solution in a 1.5ml plastic centrifuge tube, add deionized water dropwise to 1ml, fasten the cap of the centrifuge tube and place it in an ultrasonic wave until a large number of bubbles appear in the solution, stop the ultrasound, take out the test tube, and open the top cover, and then quickly add 0.4ml, 0.1mol / L FeCl 2 ethanol solution, fasten the test tube lid, quickly place the centrifuge test tube in a high-speed centrifuge, turn on the power, and adjust the acceleration of the centrifuge to 11g.

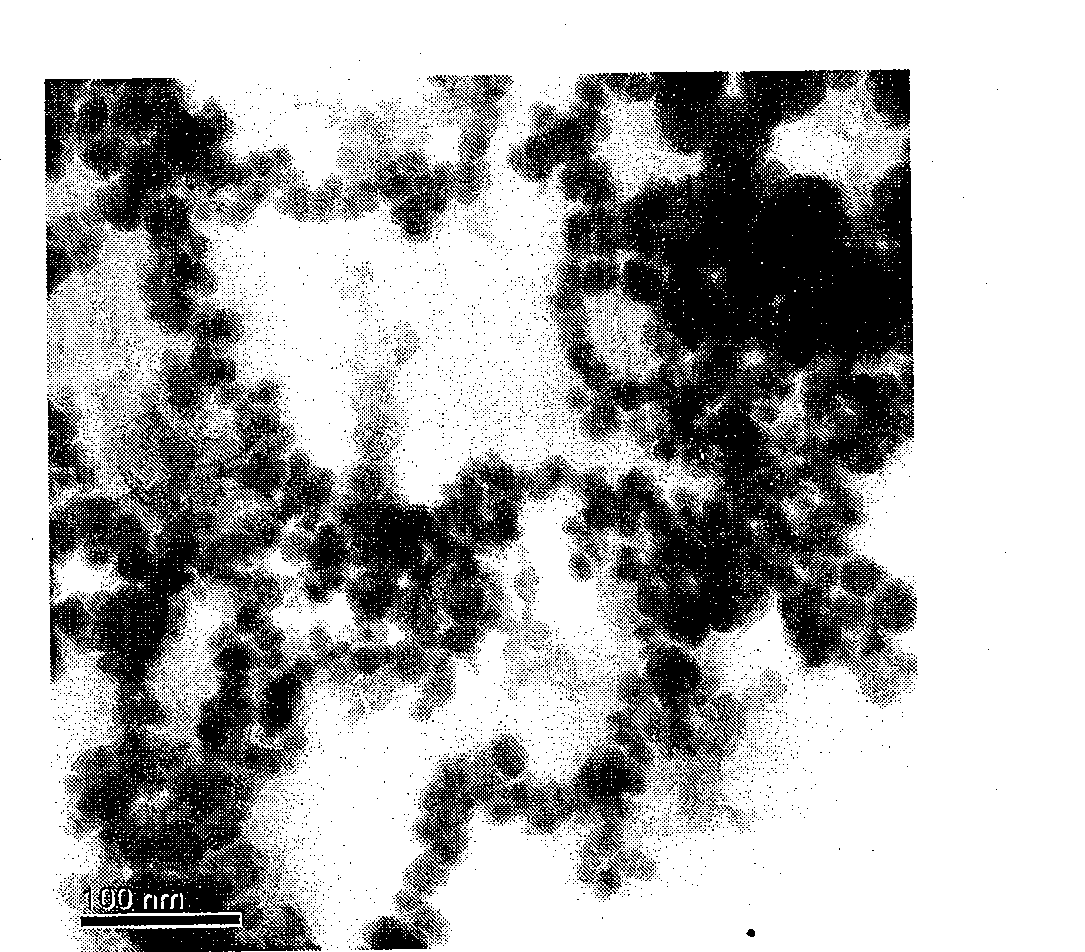

[0024] After reacting for 2-5 minutes, turn off the power, wait for the high-speed centrifuge to stop completely, take out the centrifuge test tube, a black precipitate will form at the bottom of the test tube, wash the precipitate with deionized water and alcohol f...

Embodiment 2

[0027] Prepare FeCl with a molar concentration of 0.2mol / L respectively 2 ethanol solution and KBH 4 Aqueous solution, wherein deionized water was added dropwise to 0.8ml, the acceleration of the centrifuge was adjusted to 12g, and other conditions and steps were exactly the same as in Example 1. The obtained product Fe powder is stored in absolute ethanol, and the structure and morphology of the product are characterized by XRD and TEM respectively. The obtained product has a diameter of about 12 nanometers, high product purity, and the crystal system of the product is the same as in Example 1.

Embodiment 3

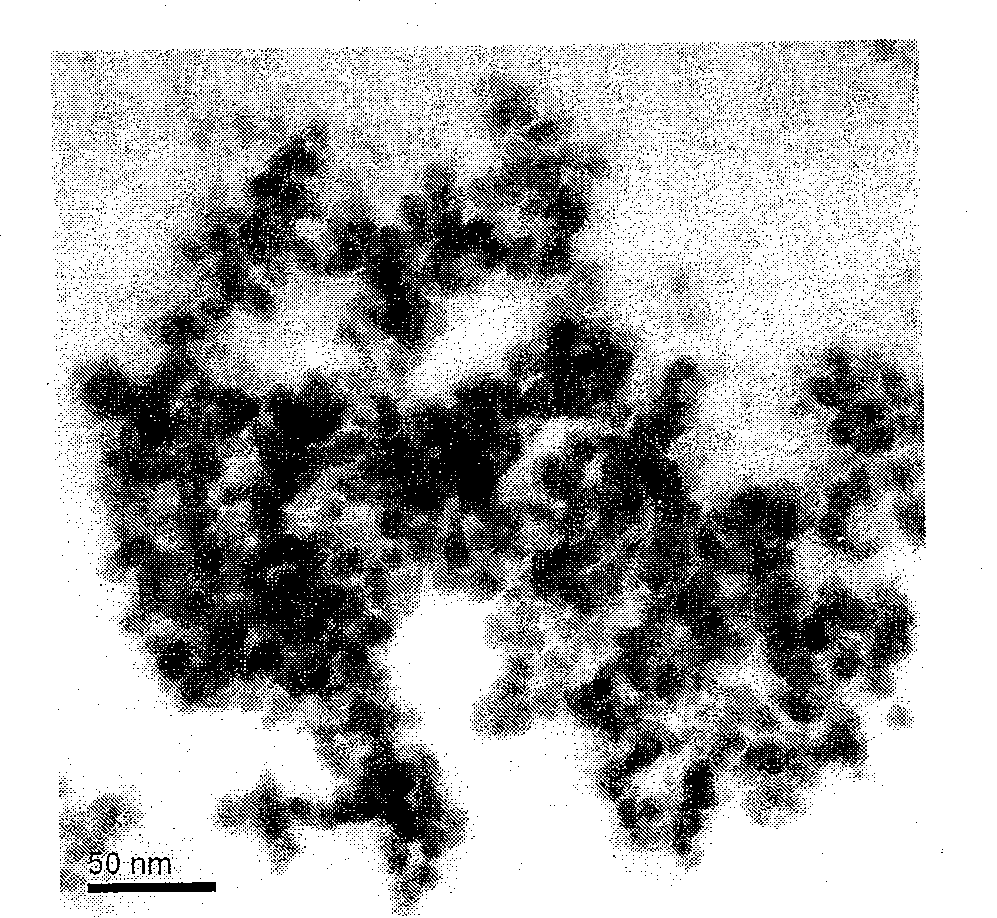

[0029] Prepare NiCl with a molar concentration of 0.1mol / L respectively 2 ethanol solution and KBH 4 of aqueous solution. Other conditions and steps are exactly the same as in Example 1. The resulting product Ni powder was stored in absolute ethanol, and the structure and morphology of the product were characterized by XRD and TEM respectively. figure 2 It can be seen from the figure that the diameter of the obtained product is about 6 nanometers, the product has high purity, and the crystal system of the product is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com