Three-speed transmission

A speed change device, the same technology, applied in the transmission device, vehicle gearbox, gear transmission device, etc., can solve the problems of low processing efficiency and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

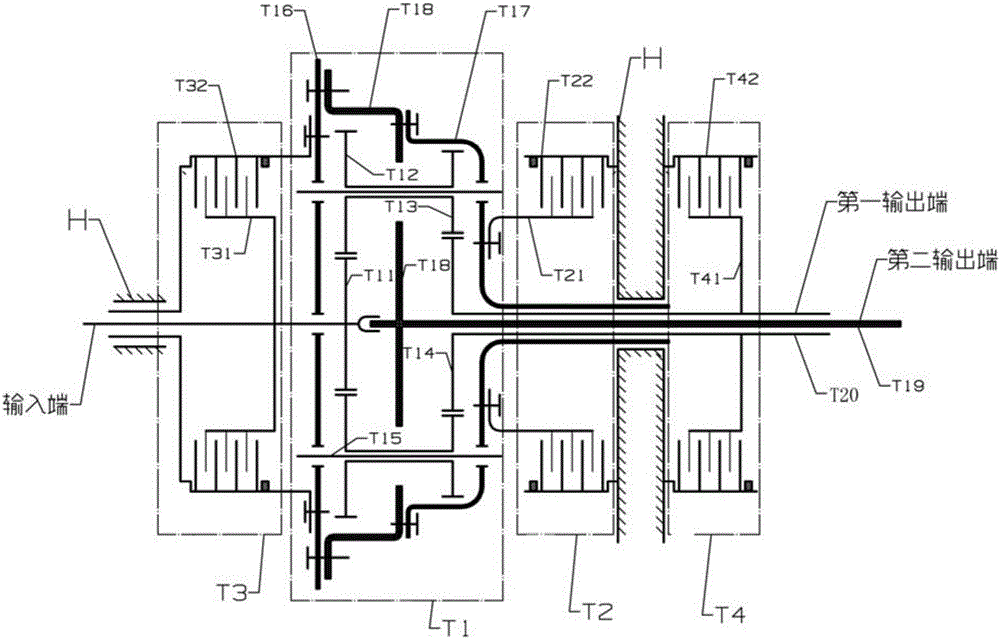

[0115] Such as Figure 3a As shown, the B clutch is a friction plate type helical surface external compression overrunning clutch, including a clutch limiter T27, a fixed component T22, a rotating component T21, a self-locking / overrunning control device and an additional clutch control device arranged on the same rotation axis.

[0116] The fixed assembly T22 includes a first force transmission drum T221 and a plurality of first friction plates T222 arranged on the first force transmission drum T221, the first friction plates T222 can slide relative to the first force transmission drum T221 in the axial direction, The first friction plate T222 and the first force transmission drum T221 rotate synchronously along the circumferential direction.

[0117] The rotating assembly T21 includes a second force transmission hub T211 and a plurality of second friction plates T212 arranged outside the second force transmission hub T211, the second friction plates T212 can slide relative to...

Embodiment 2

[0130] Such as Figure 3b As shown, the B clutch is a friction disc type helical surface compression overrunning clutch, including a clutch limit device T27 arranged on the same rotation axis, a fixed component T22, a rotating component T21, a self-locking / overrunning control device and an additional clutch control device .

[0131] The fixed assembly T22 includes a first force transmission drum T221 and a plurality of first friction plates T222 arranged on the first force transmission drum T221, the first friction plates T222 can slide relative to the first force transmission drum T221 in the axial direction, The first friction plate T222 and the first force transmission drum T221 rotate synchronously along the circumferential direction.

[0132] The rotating assembly T21 includes a second force transmission hub T211 and a plurality of second friction plates T212 arranged outside the second force transmission hub T211, the second friction plates T212 can slide relative to th...

Embodiment 3

[0148] The B clutch is a friction plate type helical surface external compression overrunning clutch, which is similar to the structure of the B clutch in Embodiment 1, the difference is:

[0149] The first force transmission drum T221 is set inside the second force transmission hub T211;

[0150] The second helicoid coupling part T24 is fixedly connected with the second force transmission hub T211; the second helicoid coupling part T24 is located in the space formed by the second force transmission hub T211, the supporting body and the first helicoid coupling part T23.

[0151] The supporting body and the first force transmission drum T221 serve as two force transmission ends of the clutch respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com