LED double-light lens for automobile headlights

An LED lamp bead and lens technology, which is applied in the field of automotive lighting, can solve the problems of not clear cut-off line of light and dark, not bright enough near light, not enough focus light on far light, etc., and achieves the effect of reducing dazzling feeling, small size and enhancing heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The LED bifocal lens for automobile headlights provided by this embodiment comprises a fixed bracket, a lens bracket, a lens, an LED lamp bead, a first reflector cup, a second reflector cup, a light cutting sheet, a light cutting sheet fixing shaft, a substrate and radiator; among them,

[0035] The lens bracket is arranged on the fixed bracket and is located on the first side of the fixed bracket, the lens is arranged on the side of the lens bracket away from the fixed bracket, and the heat sink is arranged on the fixed bracket and located on the second side of the fixing bracket corresponding to the first side, the substrate is arranged on the heat sink;

[0036] The LED lamp beads are arranged on the substrate, the first reflective cup cover is arranged above the substrate and on the upper part of the second reflective cup, and the second reflective cup is arranged on the heat sink ;

[0037] The light cutting plate fixing shaft is arranged on the fixing bracket an...

Embodiment 2

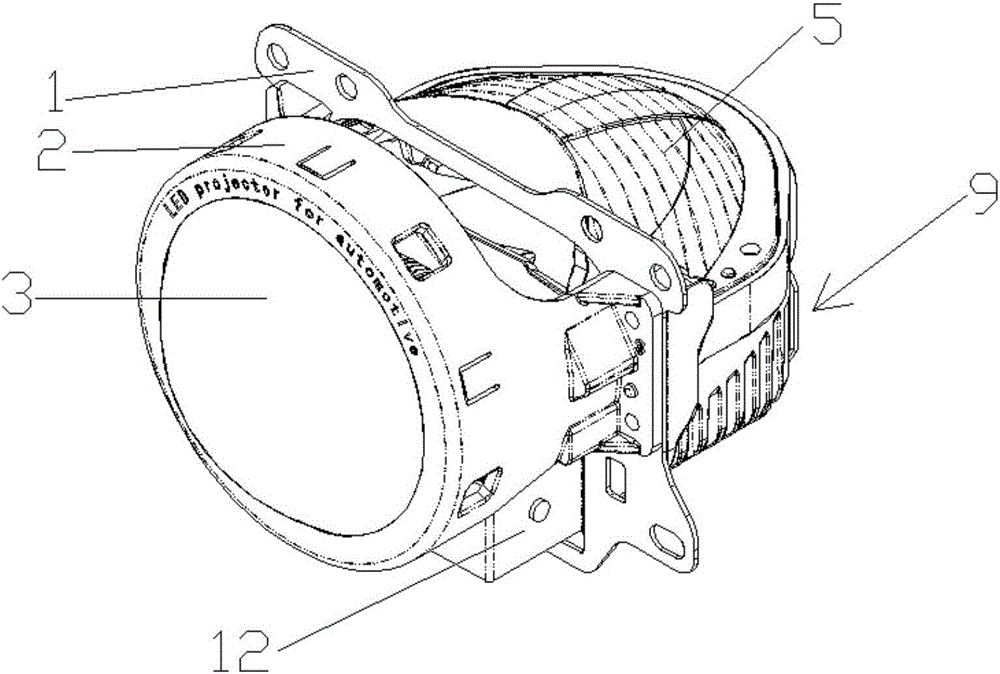

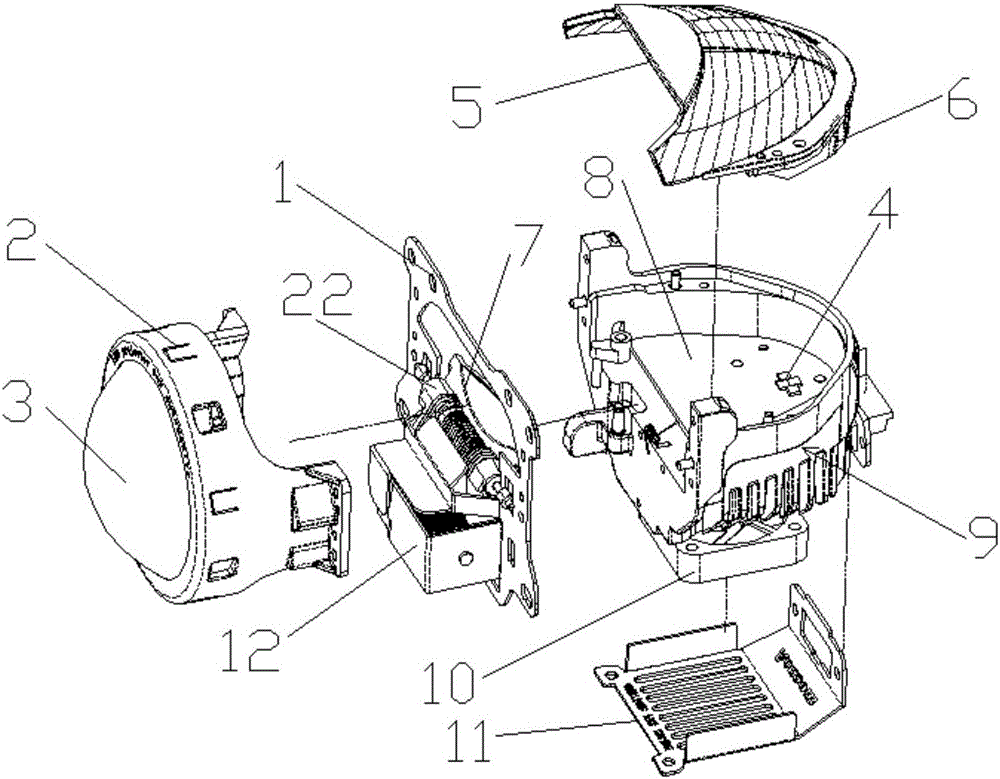

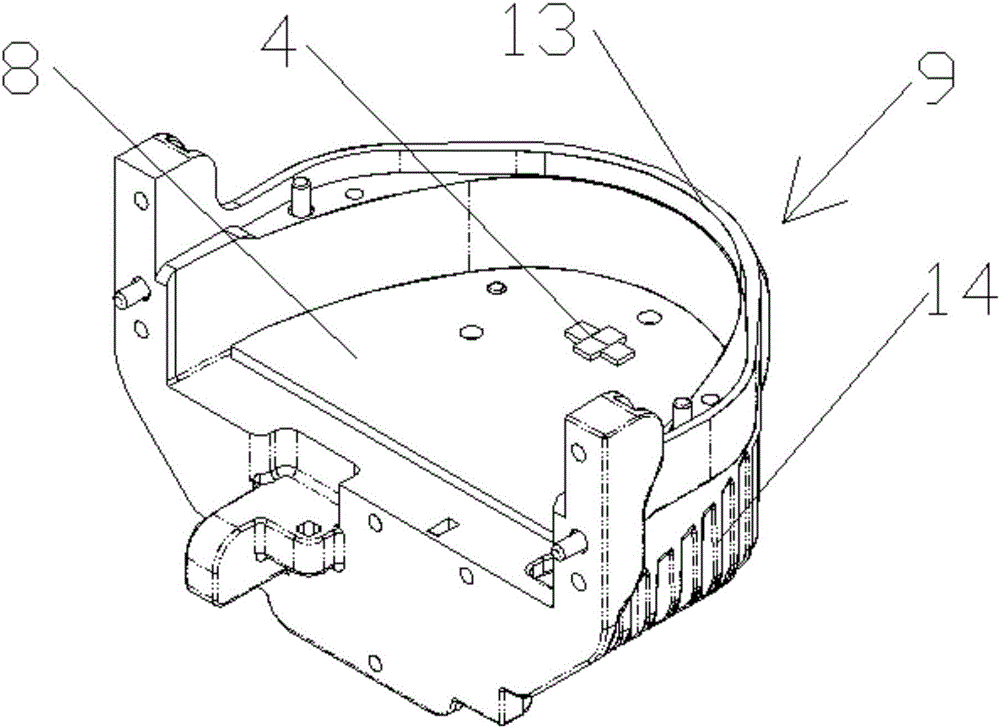

[0042] Such as Figures 1 to 5 As shown, the present embodiment provides the preferred structure of the LED bifocal lens for automobile headlights, which includes a fixed bracket 1, a lens bracket 2, a lens 3, an LED lamp bead 4, a first reflective cup 5, and a second reflective cup 6. Light cutting sheet 7, light cutting sheet fixing shaft 22, substrate 8 and radiator 9; wherein,

[0043] The lens holder 2 is arranged on the fixed holder 1 and is located on the first side of the fixed holder 1, the lens 3 is arranged on the side of the lens holder 2 away from the fixed holder 1, and the radiator 9 is arranged on the fixed bracket 1 and is located on the second side of the fixed bracket 1 corresponding to the first side, and the substrate 8 is arranged on the heat sink 9;

[0044] The LED lamp beads 4 are arranged on the substrate 8, the first reflective cup 5 is covered above the substrate 8 and located on the upper part of the second reflective cup 6, and the second reflectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com