Check assembly for hydraulic test of multi-opening disc type piece

A disc-shaped, multi-opening technology, used in the testing of machine/structural components, measuring devices, elasticity testing, etc., can solve problems such as the inability to isolate non-load-bearing parts, and the inability to perform hydraulic testing on multi-opening disc-shaped parts. , to achieve the effect of not bearing pressure, preventing deformation, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

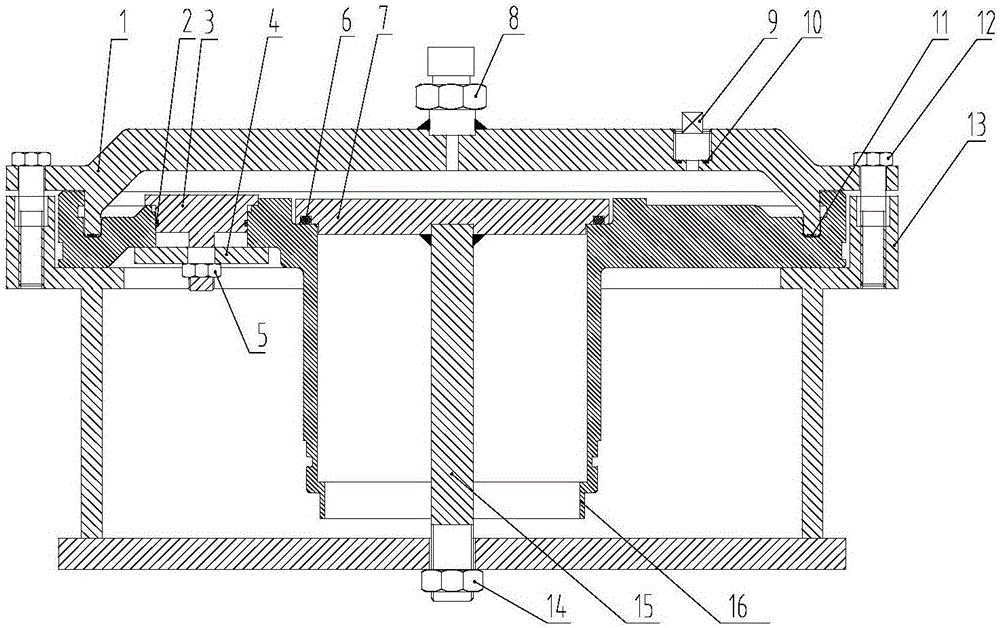

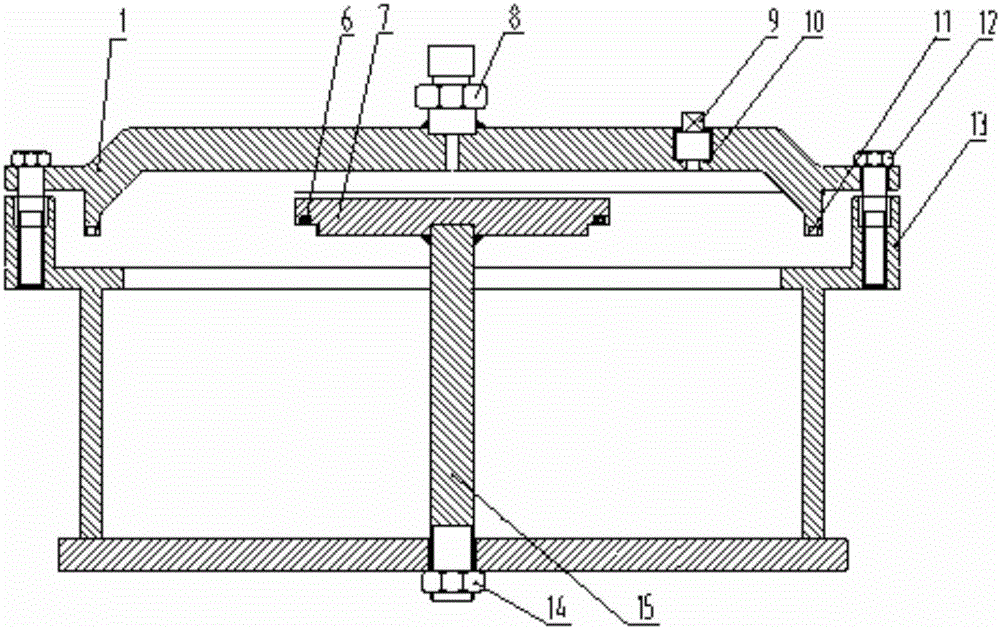

[0028] This embodiment is an inspection tool for hydraulic testing of multi-opening disc shapes.

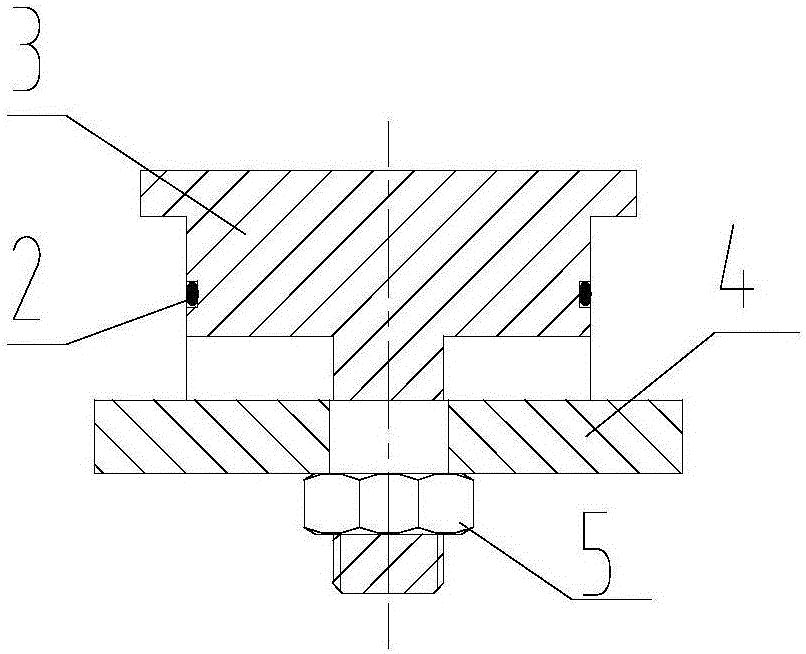

[0029] Such as figure 1 As shown, this embodiment includes an upper plug 1 , an opening plug 3 , a cylinder plug 7 , a base 13 , a water inlet joint 8 and a pressure measuring hole plug 9 . The opening blocking cover 3 is an independent structure, which is used in conjunction with the upper blocking cover 1 and the cylinder blocking cover 7 to realize the sealing of the multi-opening disc shape 16 .

[0030] In this embodiment, the cylinder blocking cover 7 is located in the base 13 and is installed in the center of the upper surface of the bottom plate of the base through a connecting rod 15 . The upper blocking cover 1 is fixed on the upper surface of the base by bolts 12 . The water inlet joint 8 is fixed at the center of the upper surface of the upper blocking cover, and is connected with the water inlet hole at the center of the upper blocking cover. A pressure measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com