Tool type masonry flexural strength test lateral loading device

A technology of lateral loading and bending strength, which is applied in the direction of measuring devices, strength characteristics, and the use of stable bending force to test the strength of materials, etc., can solve the problems of similar patent applications that have not yet been published, and achieve accurate and reliable detection data. The effect of convenient loading control and flexible disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

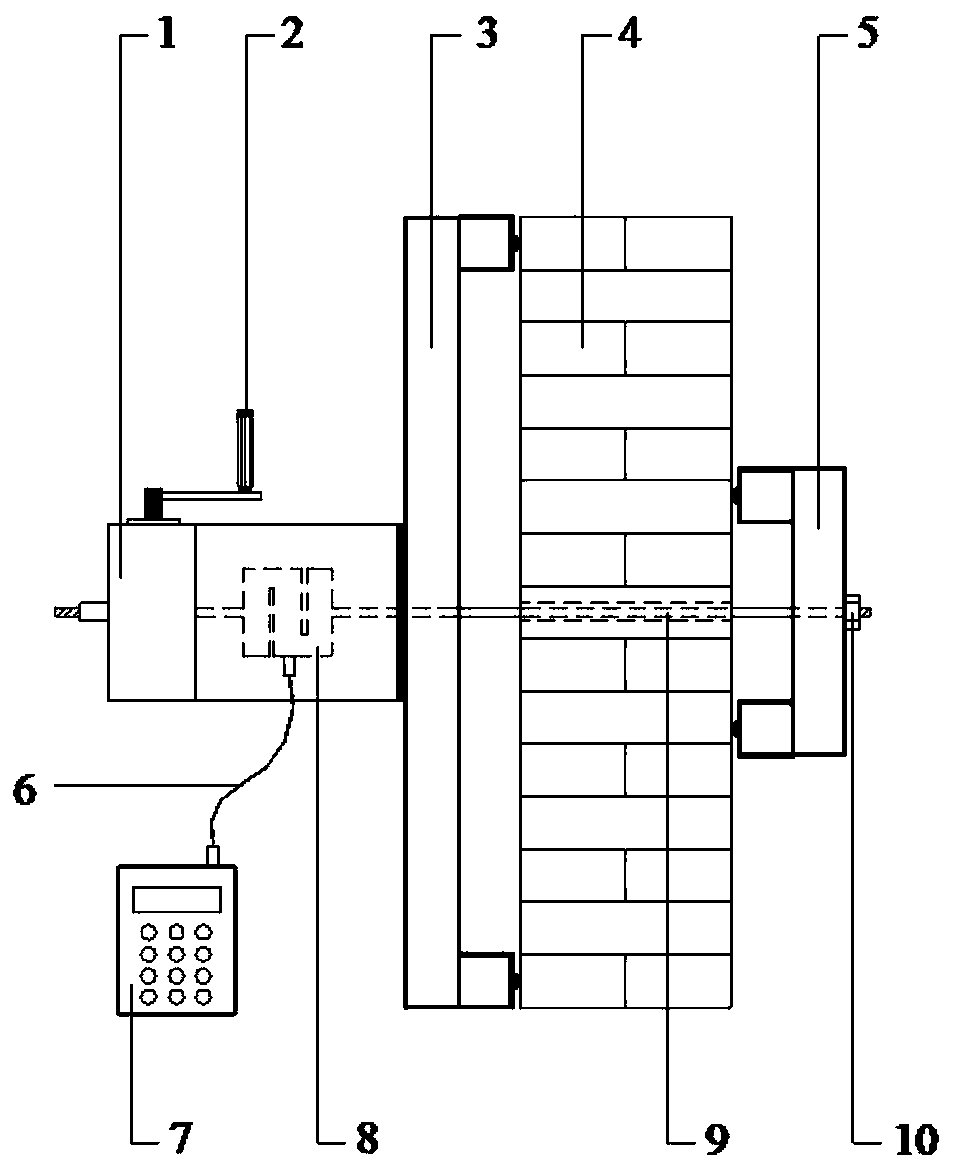

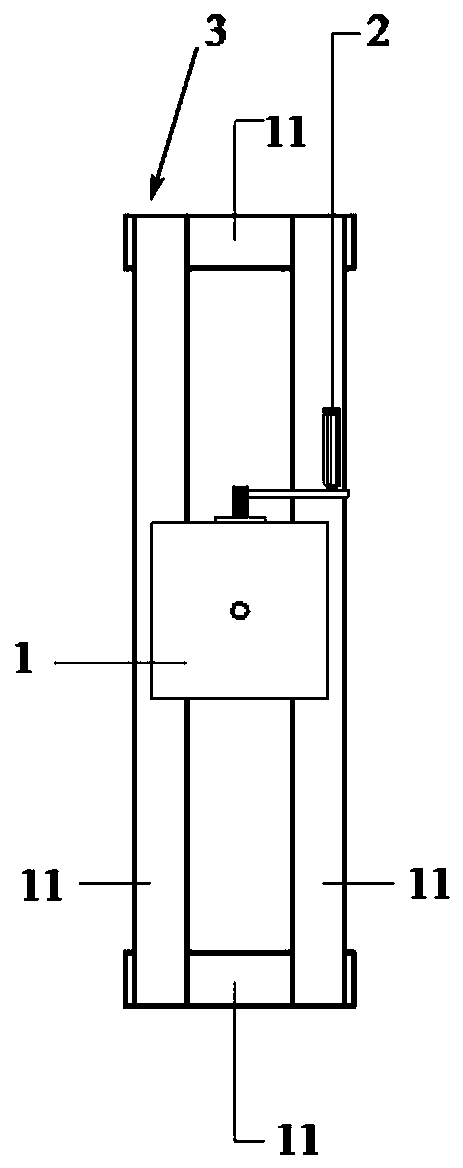

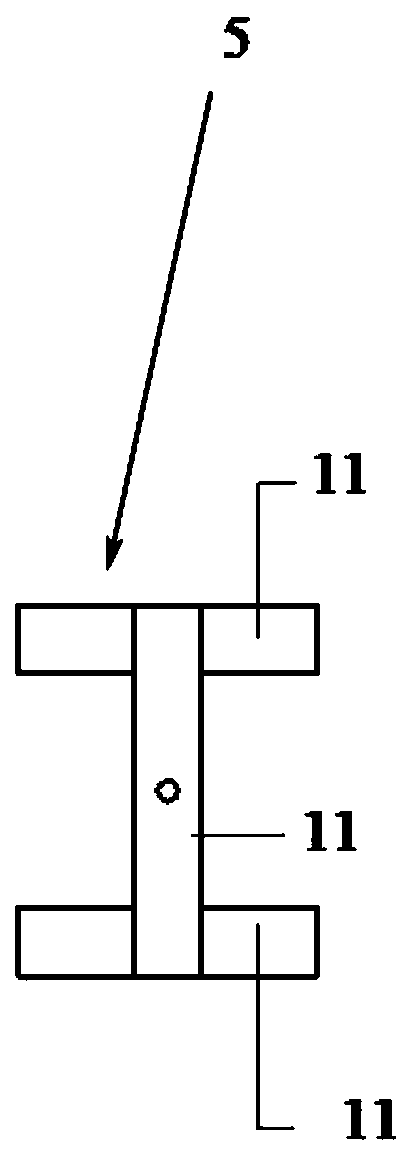

[0031] Such as figure 1 As shown, in order to measure the bending strength of the masonry through-joint standard test piece 4, this embodiment utilizes a group of steel reaction frames and a screw jack 1 with a steel tie rod 9 and an S-type tension sensor 8 to realize vertical placement. Lateral loading of the joint-through bending specimen 4. Among them, the screw jack 1 can apply tension, the S-type tension sensor 8 attached to the screw jack 1 is connected to the steel pull rod 9, the S-type tension sensor 8 is connected to the tension collector 7 with a cable 6, and the tension value measured by the test is determined by the tension Collector 7 directly displays and records. Such as figure 2 , 3 As shown, the steel reaction frame is composed of two distribution beams with different lengths, including a mouth-shaped distribution beam 3 and an I-shaped distribution beam 5, which are respectively placed on both sides of the joint-through bending test piece 4 during the te...

Embodiment 2

[0039] The loading device provided by this embodiment is the same as that of Embodiment 1, the difference is that:

[0040] Such as Figure 4 , 5 , 6, test the flexural specimen 12 of the tooth gap. In the laboratory, in order to measure the bending tensile strength of the masonry specimen along the tooth gap, i.e. the tooth gap flexural strength, the present embodiment can be used according to the following steps:

[0041] (1) According to Figure 4 , place the tooth gap bending test piece 12 on a smooth level ground;

[0042] (2) Drill a through hole in the center of the middle layer of bricks in the vertically placed tooth seam bending test piece 12 (the casing can also be embedded in the hole when the masonry test piece is built), and the diameter of the through hole is smaller than that of the steel tie rod 9 2mm larger in diameter;

[0043] (3) Reaction frames are installed on both sides of the tooth seam bending test piece 12, and the steel tie rods 9 pass through ...

Embodiment 3

[0048] The loading device provided by this embodiment is the same as that of Embodiment 1, the difference is that:

[0049] Such as Figure 7 As shown, in the masonry building site, the through-joint flexural strength of the existing wall materials is measured.

[0050] In this embodiment, the on-site sampling detection of the flexural strength of the masonry joint can be completed according to the following steps:

[0051] (1) On the brick wall 14 of a brick-concrete structure house, select the wall under the window under the window hole 13 and the vertical pressure is zero as the measurement area, that is, the joint bending strength measurement area 16, the length of the wall section (b) and The height (h) is greater than 900mm;

[0052] (2) According to Figure 7 , Drill a through hole at the drilling position 15 at a height of 450mm from the top of the wall in the middle of the wall section, the center of the through hole is located in the center of the brick, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com