Device and method for testing fogdrop content in smoke gas

A test device and droplet technology, which is applied in the direction of measuring device, analysis of gas mixture, gas analyzer structure details, etc., can solve the problem of complicated correction procedures, high sampling operation accuracy, and inability to measure droplets with full particle size, etc. problem, to achieve the effect of improving test accuracy, simplifying sampling, and reducing sampling error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

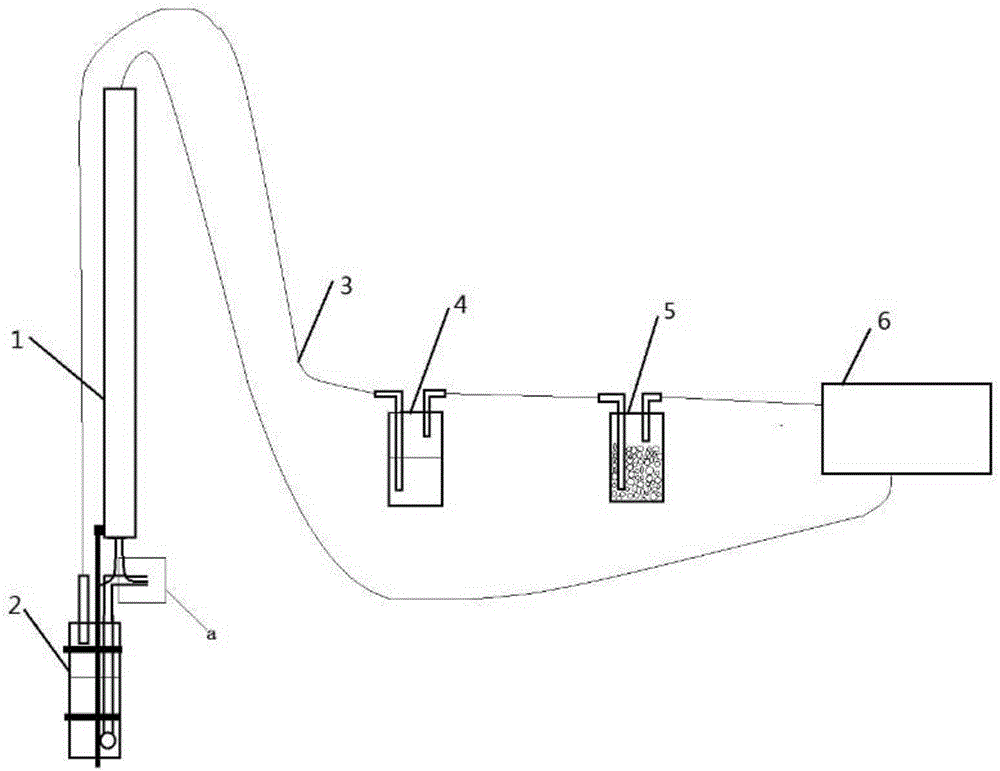

[0038] Such as figure 1 As shown, the present embodiment comprises a Pitot tube (1), a droplet absorbing bottle (2), a flexible pipe (3), an acid gas absorbing bottle (4), a drier (5), an intelligent dynamic pressure balance smoke sampling pump (6 ).

[0039] During the measurement, the Pitot tube (1) and the droplet absorption bottle (2) are fixed together, the pressure sensing port of the Pitot tube (1) is as close as possible to the air inlet of the droplet absorption bottle (2), and the Pitot The test surface of the dynamic pressure tube of the trusteeship (1) is parallel to the end face of the air inlet of the droplet absorption bottle (2); It is connected through a hose (3); the gas outlet of the droplet absorption bottle (2) is sequentially connected to the sampling port of the acid gas absorption bottle (4), the dryer (5) and the intelligent dynamic pressure balance smoke sampling pump (6).

[0040] The testing method of the present embodiment comprises the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com