Intelligent route inspection method for abnormal equipment based on transformer route inspection robot

An inspection robot and intelligent inspection technology, applied in the sequence/logic controller for program control, instruments, measuring electricity, etc., can solve the problems of lack of data, inability to analyze the law of equipment failure, and low utilization rate of robots. Achieve the effect of improving the utilization rate and detection rate, improving the efficiency of personnel maintenance, and reducing the cost of personnel maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

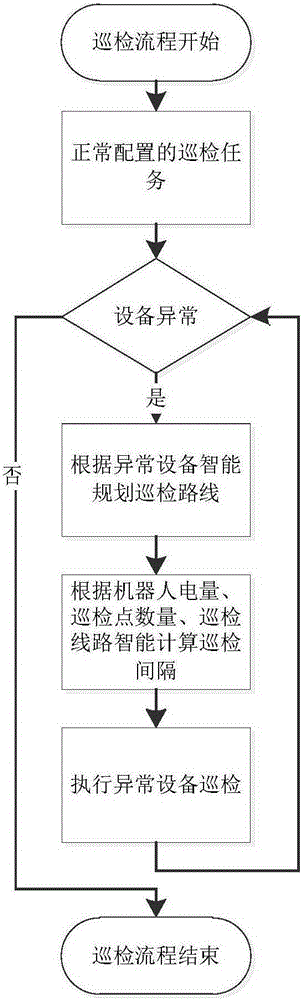

[0034] Such as figure 1 As shown, an intelligent online inspection method for substation equipment based on the substation intelligent robot, its steps are:

[0035] Step 1: Execute the routine inspection tasks manually compiled by the substation inspection robot system, and conduct substation equipment inspections;

[0036] Step 2: After the task is completed, intelligently analyze the collected equipment image and sound data, and use the infrared expert database, equipment inspection items and other information databases as the judgment basis to obtain all faults or alarms after the execution of the inspection task A collection of abnormal devices prompted;

[0037] Step 3: Intelligently plan abnormal equipment inspection lines according to the collection of abnormal equipment;

[0038] Here, it should be known that, on the premise of ensuring that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com