MATLAB-based suit cutting and splicing calculation method for silicon steel sheets

A calculation method and technology for silicon steel sheets, applied in the directions of calculation, design optimization/simulation, special data processing applications, etc., can solve problems such as changes in the combination scheme, and achieve the effect of improving calculation speed, calculation efficiency, and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

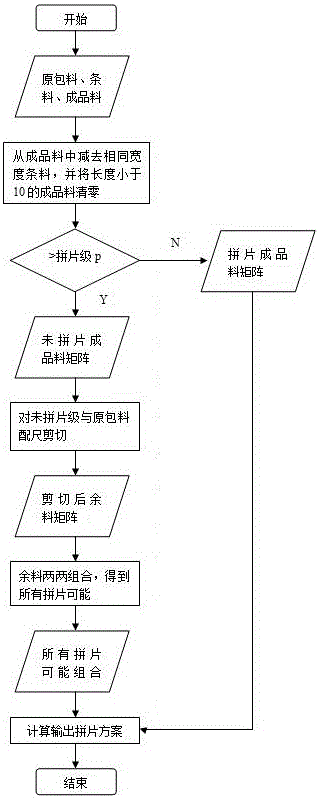

[0020] Embodiment 1, the process refers to the appended figure 1 .

[0021] Calculation of the fixed-width raw packaging material patchwork plan, directly place the existing raw packaging material, strip material and finished material data in the fixed position of the Excel file, or directly paste the data in the corresponding data position, and run the patchwork program on the computer to obtain the patchwork plan ;

[0022] The specific process is as follows:

[0023] 1. Start;

[0024] 2. Data input of raw packaging material, strip material and finished product material;

[0025] 3. Subtract the strips of the same width from the finished material, and clear the finished material whose length is less than 10;

[0026] 4. If it is not > piece level p, then form the finished material matrix of the piece, and calculate and output the piece scheme, and end;

[0027] 5. If > Piece level p, the finished material matrix is not pieced together;

[0028] 6. Cutting the scales...

Embodiment 2

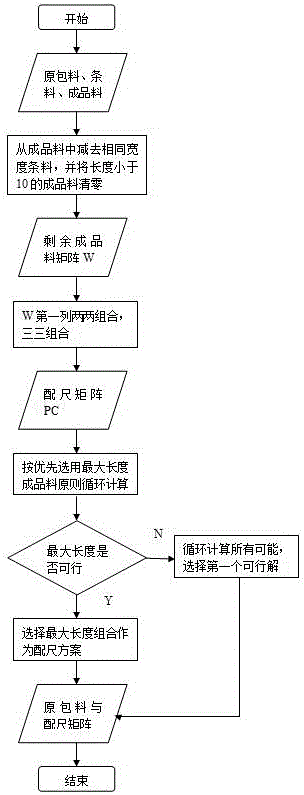

[0033] Embodiment two, flow process refers to attached figure 2 .

[0034] Fixed-width and non-fixed-width raw packaging material matching calculation, directly place the existing raw packaging material, strip material and finished material data in the fixed position of the Excel file, or directly paste the data as the corresponding data position in the program, and run the splicing program Get the puzzle plan.

[0035] The specific process is as follows:

[0036] 1. Start;

[0037] 2. Data input of raw packaging material, strip material and finished product material;

[0038] 3. Subtract the strips of the same width from the finished material, and clear the finished material whose length is less than 10;

[0039] 4. The remaining finished materials form a matrix W;

[0040] 5. The first column of the matrix W is combined in pairs and in threes;

[0041] 6. Scaling matrix PC;

[0042] 7. Calculate circularly according to the principle of giving priority to the selectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com