Method for optimally selecting thin-coal-seam long-wall fully-mechanized mining-face coal mining method

A technology of fully mechanized mining face and coal mining method, applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as high mining cost and decision-making influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

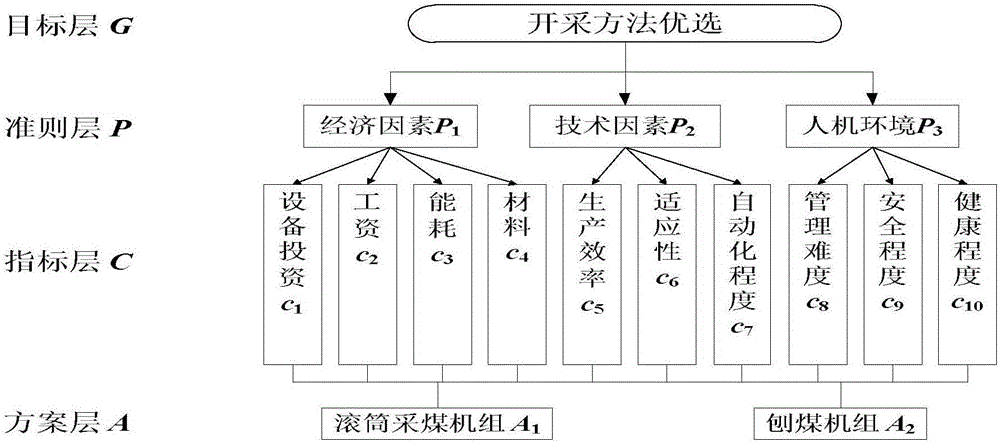

[0032] Such as Figure 1~2 As shown, a. According to the theory of system engineering and mining engineering, the decision-making index system for the selection of mining methods in thin coal seam longwall fully mechanized mining face is established, which integrates three criteria of economic factors, technical factors and human-machine environmental factors. Among them, economic factors Factors include four indicators of equipment investment, wages, energy consumption and materials; technical factors include three indicators of production efficiency, adaptability and degree of automation; human-machine environment factors include three indicators of management difficulty, safety and health; the program layer includes There are two schemes for the mining method of the thin coal seam with the drum shearer and the mining method of the plow;

[0033] b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com