High-voltage power transmission strain clamp residual life prediction method

A technology of life prediction and tension clamp, applied in prediction, instrument, data processing application, etc., can solve problems such as prediction, inability to carry out remaining life, etc., and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

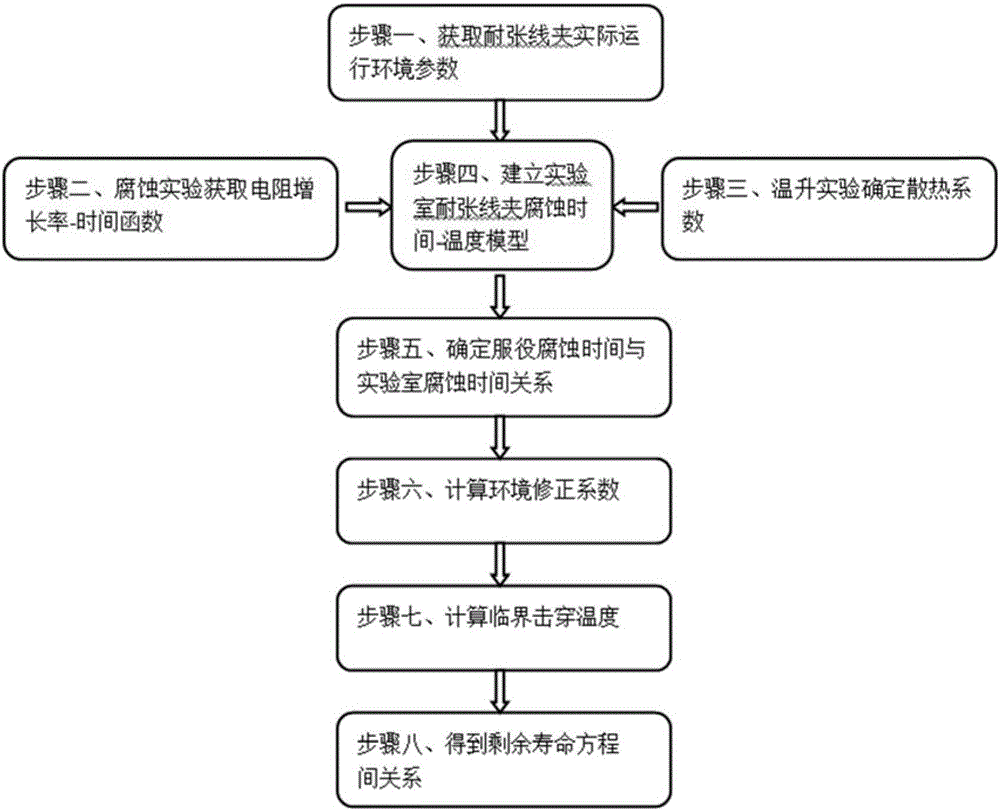

Method used

Image

Examples

Embodiment 1

[0142] The following is an embodiment of the present invention, which is aimed at NY-400 tension clamps that have been in service for 40 years in a certain area. The specific process of remaining life prediction is as follows:

[0143] Step 1: Obtain the actual operating environment parameters of the tension clamp;

[0144] For the NY-400 tension clamp in service in a certain area, measure and calculate the average value of each parameter in the working environment of the tension clamp, atmospheric pressure P = 1atm, air flow velocity v = 5m / s, outer diameter of the clamp d =45mm, the area of heat dissipation surface F=4.5×45×3.14cm 2 , clamp temperature θ=60℃, air temperature θ 0 =20°C, passing current I=900A and rainwater pH=6.5;

[0145] Step 2: Corrosion rate experiment;

[0146] For the NY-400 strain clamps that have been pressed with aluminum-steel wires, the sodium chloride solution with a mass fraction of 5% was used as the corrosion medium in the laboratory, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com