Frame strander rotary air bag

A frame stranding machine and air bag technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of poor sealing, short service life, complex heat dissipation structure, etc., and achieve good sealing, convenient processing and manufacturing, and location Set flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

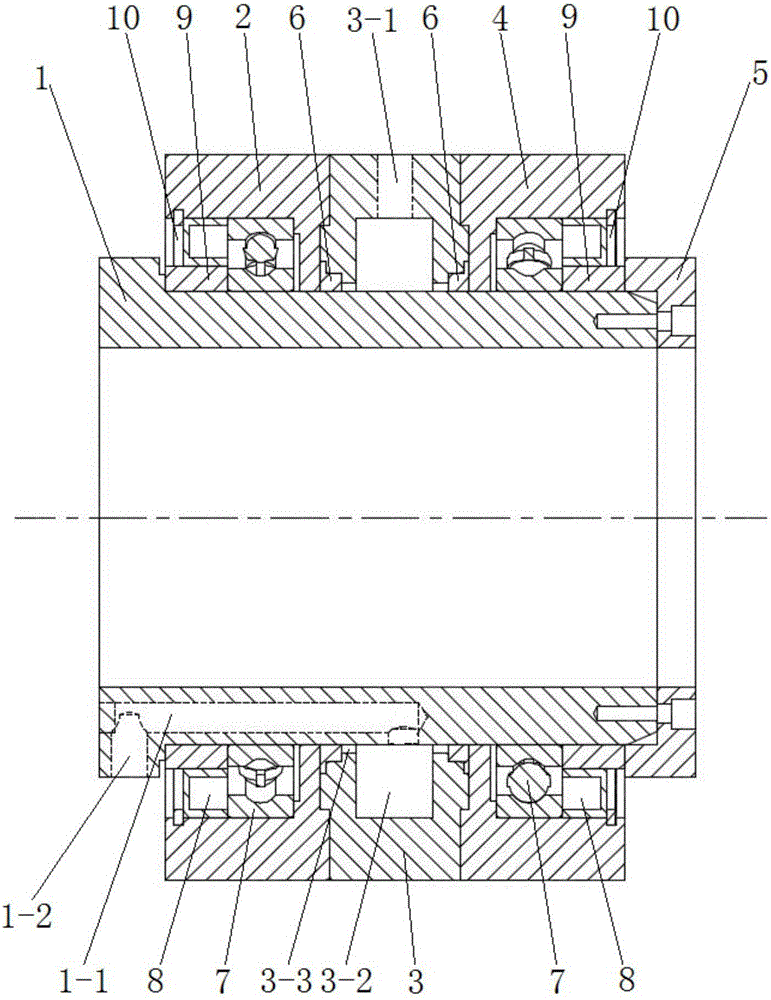

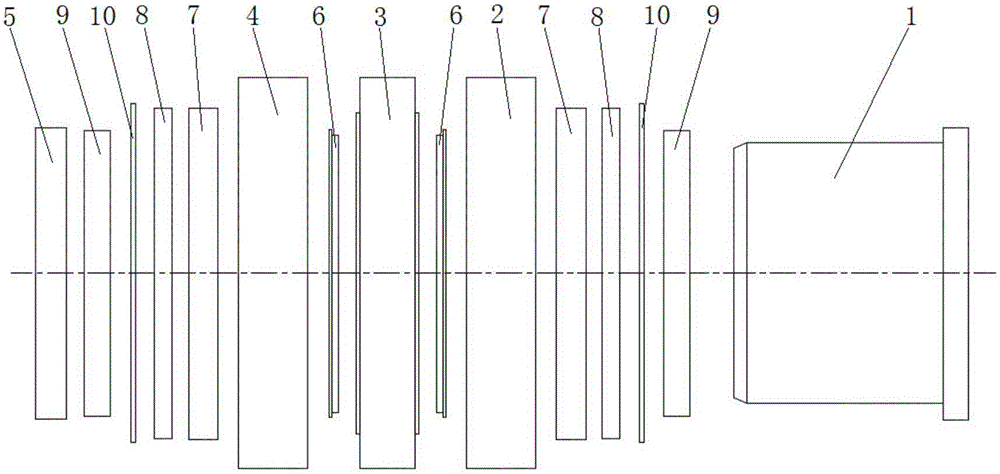

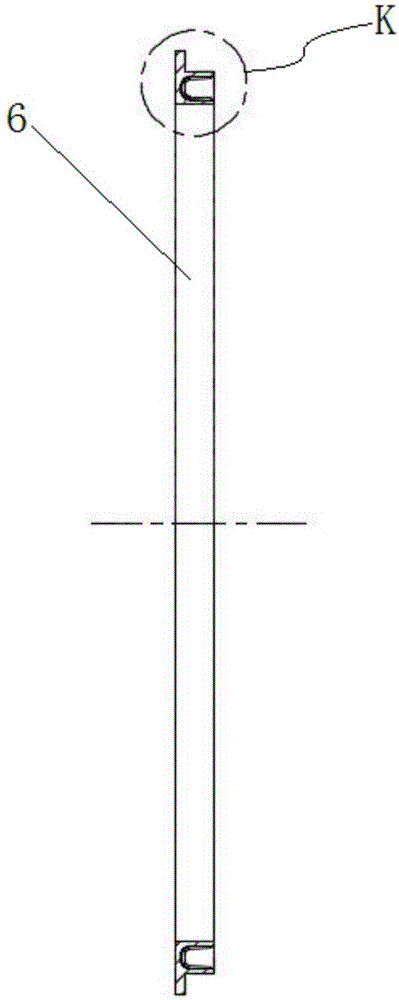

[0039] combine Figure 1 to Figure 4As shown, a rotating air bag of a frame stranding machine in this embodiment includes a shaft sleeve 1, an inner bearing sleeve 2, a sealing sleeve 3, an outer bearing sleeve 4 and a fixed sleeve 5 installed at the end of the shaft sleeve 1, and the shaft sleeve 1 One end has a shoulder structure, the inner bearing sleeve 2, the sealing sleeve 3 and the outer bearing sleeve 4 are sleeved on the shaft sleeve 1 in turn, and the inner bearing sleeve 2, the sealing sleeve 3 and the outer bearing sleeve 4 are fixedly connected, preferably Ground, the inner bearing sleeve 2, the sealing sleeve 3 and the outer bearing sleeve 4 are fixedly connected by bolts, which is convenient for disassembly and maintenance; There is a bearing assembly, an air chamber 3-2 and sealing grooves located on both sides of the air chamber 3-2 are arranged between the sealing sleeve 3 and the shaft sleeve 1, and a rotating sealing ring 6 is installed in the sealing groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com