Transfer system and transfer method of microelements, manufacturing method, device and electronic device

A transfer system and transfer method technology, applied in the field of electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

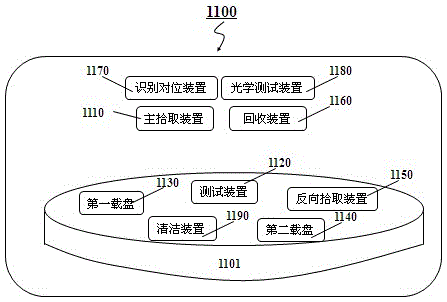

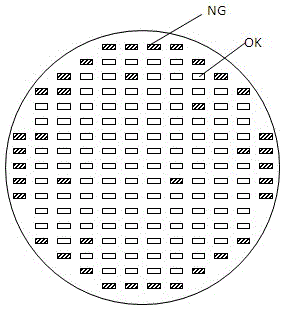

[0064] Embodiments of the present invention describe a transfer system for transferring a micro-element and a method for transferring a micro-element array using the transfer system. Among them, the micro-element array can be micro-LED devices, diodes, transistors, integrated circuit (IC) chips, etc., and its size can be 1-5000 μm, but it is not necessarily limited thereto, and some aspects of the embodiment can be applied to larger and larger smaller size.

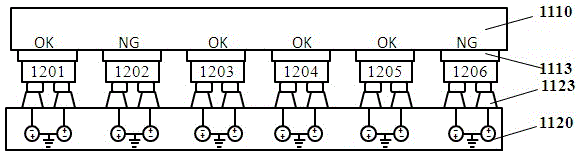

[0065] The transfer system has a main picker for picking up or releasing micro components, the main picker has a series of arrays of picker units, each picker unit has a size (eg length or width) of 1 to 5000 μm, for example 10 to 100 μm, or 100 ~500 microns, or 1000 ~5000 microns. The transfer system is also provided with a test device, which has a test circuit and a test platform. A series of test electrodes are arranged on the surface of the test platform. The electrode of the component is in contact with the test el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com