Ground wire device with early warning and electricity testing function

A technology of grounding wire and electricity inspection, applied in the parts, coupling devices, circuits of connecting devices, etc., can solve problems such as loss, user inconvenience, prolong maintenance time, etc., achieve good stability and reliability, and simple threaded connection structure. , the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

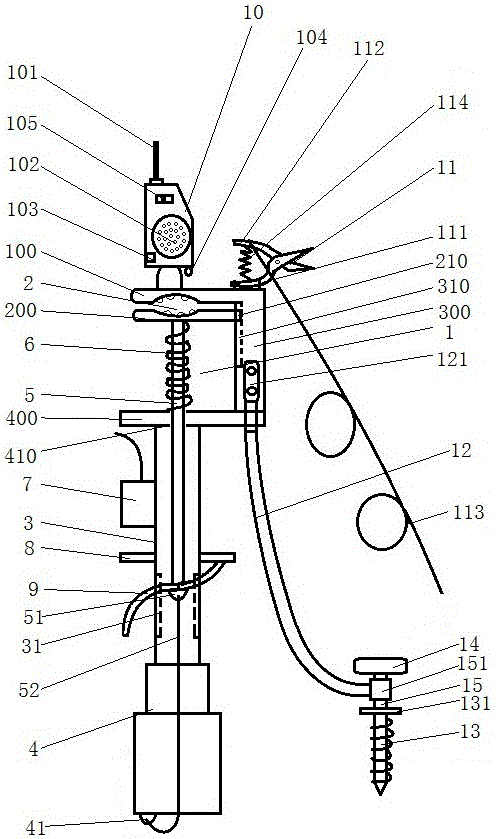

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A grounding wire device with early warning and electric inspection functions, including insulating rods, grounding leads and grounding clamps, is characterized in that it is equipped with an upper top plate (100), a splint (200), a side plate (300) and a lower bottom plate ( 400) composed of a junction frame clamp (1) opening to one side, wherein the upper top plate (100), the splint (200) and the lower bottom plate (400) are parallel to each other and are in the same section, the upper top plate (100) and the lower bottom plate (400 ) are respectively connected with the upper end and the lower end of the side plate (300), the side plate (300) is provided with a chute (310), and the splint (200) is provided with a slider (210) matching the chute (310) , the splint (200) is connected to the side plate (300) through the slider (210) and the chute (310), so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com