Tube assembly and humidification system thereof

A humidification system and lamp technology, applied in air humidification systems, heating methods, electrical components, etc., can solve the problem of low thermal radiation efficiency of infrared light sources, and achieve the effect of improving light utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

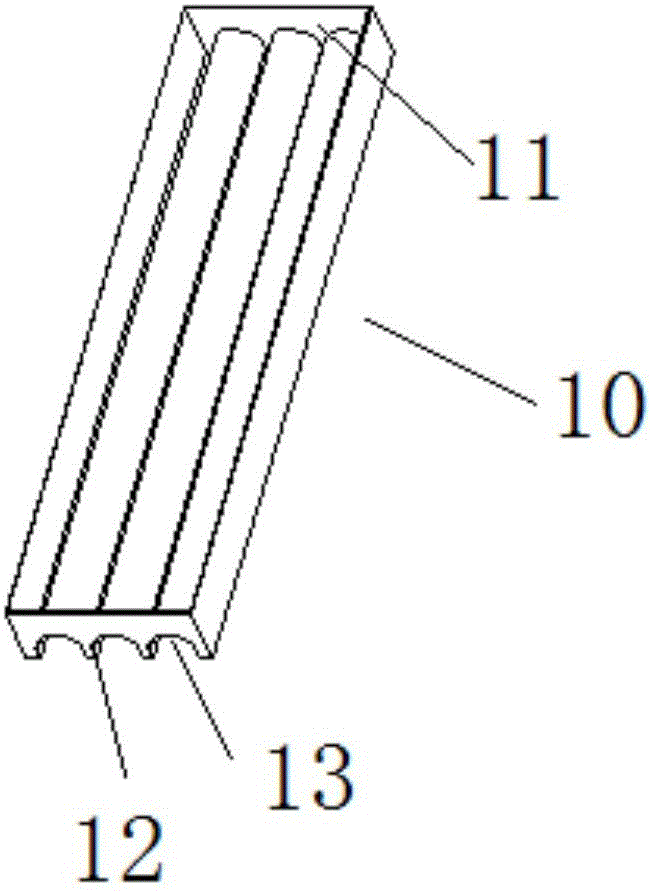

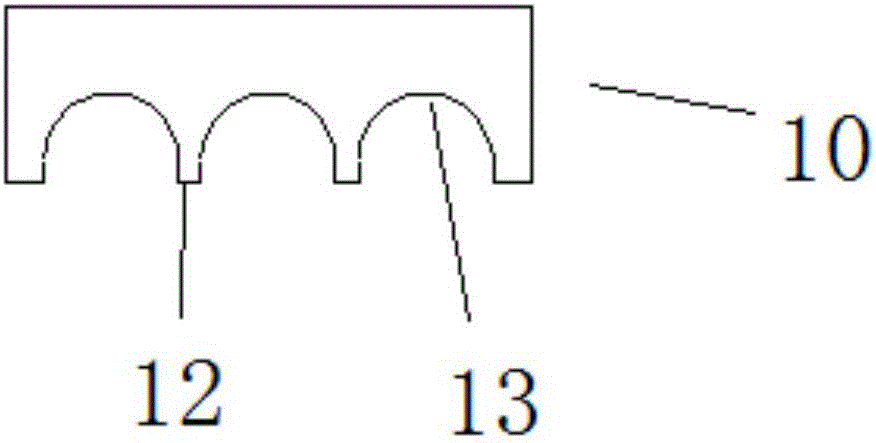

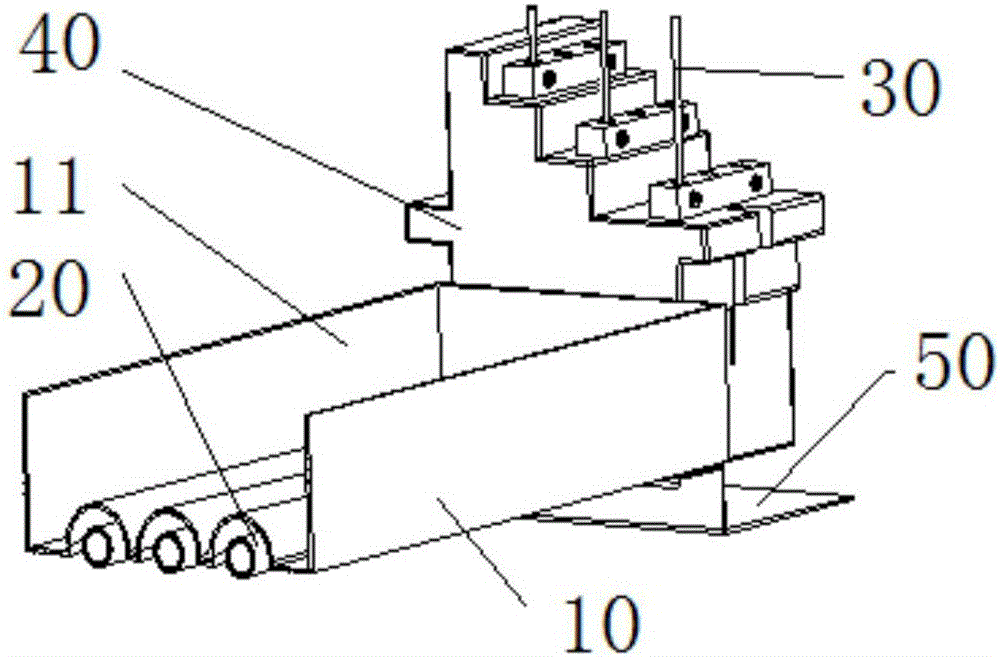

[0038] The lamp tube assembly of the humidifier provided in this embodiment includes: three infrared light sources, and a lampshade 10, such as image 3 As shown, the lampshade 10 is formed with three reflective spaces corresponding to the three infrared light sources independently on the side facing the infrared light source, that is, each infrared light source has an independent reflective space, and the inner surface of the reflective space is a reflective surface. Guide the light to a predetermined direction, so that the light emitted by each infrared light source can follow the ideal radiation path under the action of the reflective surface, and the heat radiation can effectively spread to the preset position (the water surface on the humidifier). Since each infrared light source has an independent reflective space, each infrared light source does not affect each other, which improves the light utilization rate of each infrared light source, and also avoids the heat radiat...

Embodiment 2

[0051] The humidification system provided in this embodiment includes: a humidification water tank 60 , and the lamp assembly as described in Embodiment 1 arranged above the humidification water tank 60 , so it has all the advantages of Embodiment 1. The lamp assembly cooperates with the humidifying water tank 60 to input cooling water into the humidifying water tank 60 as pre-heated water to increase the temperature of the water in the humidifying water tank 60 and further improve the humidification efficiency.

[0052] The liquid inlet of the liquid storage tank 11 communicates with the water inlet pipe 70 , and the external preheated water passes through the water inlet pipe 70 and the liquid inlet in turn to reach the liquid storage tank 11 and be heated. The liquid outlet is connected to the humidification water tank 60 through a water outlet pipe 80, such as Figure 4 As shown, the liquid outlet is located at the bottom of the liquid storage tank 11, and the liquid in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com