X-ray absorption measurement system

A measurement system and x-ray technology, applied in the field of high-brightness x-ray absorption spectroscopy equipment, can solve the problems of lack of x-ray source and difficulty in obtaining high x-energy resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

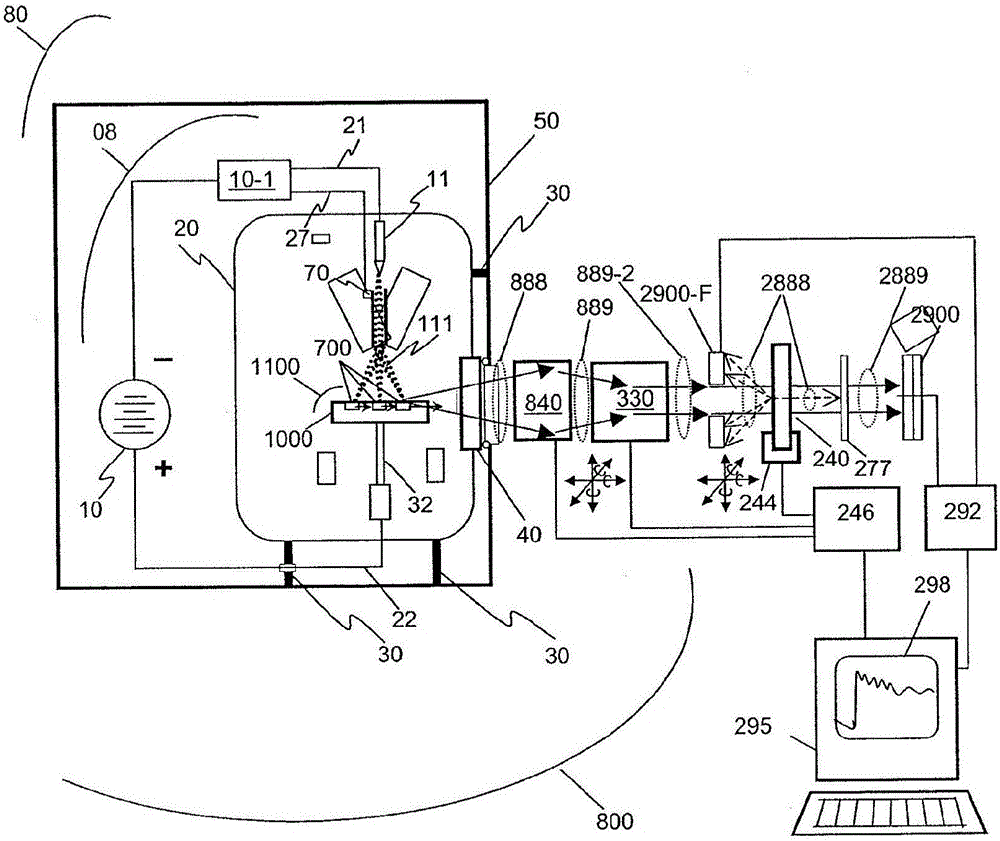

[0036] X-ray Absorption Spectroscopy System

[0037] image 3 An embodiment of the invention for an x-ray absorption spectroscopy system is schematically shown.

[0038] The x-ray generator 08 includes a vacuum environment (usually 10 -6 torr or better), the vacuum environment is usually maintained by sealing the vacuum chamber 20 or using active suction, and is made with sealed electrical leads 21 and 22, the high voltage from the outside of the vacuum chamber 20 from the electrical leads 21 and 22 The negative and positive terminals of the source 10 are passed to the various components inside the vacuum chamber 20 . The x-ray source 80 typically includes a bracket 30 that secures elements of the x-ray generator 08, such as the vacuum chamber 20, to the housing 50, and the housing 50 may additionally include a shielding material, such as lead, to prevent x-rays from being emitted by the source device. 80-A radiates in undesired directions. Inside the vacuum chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com