Isobutane dehydrogenation catalyst and preparation method thereof

A dehydrogenation catalyst, isobutane technology, applied in catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of poor stability and low activity of isobutane dehydrogenation catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

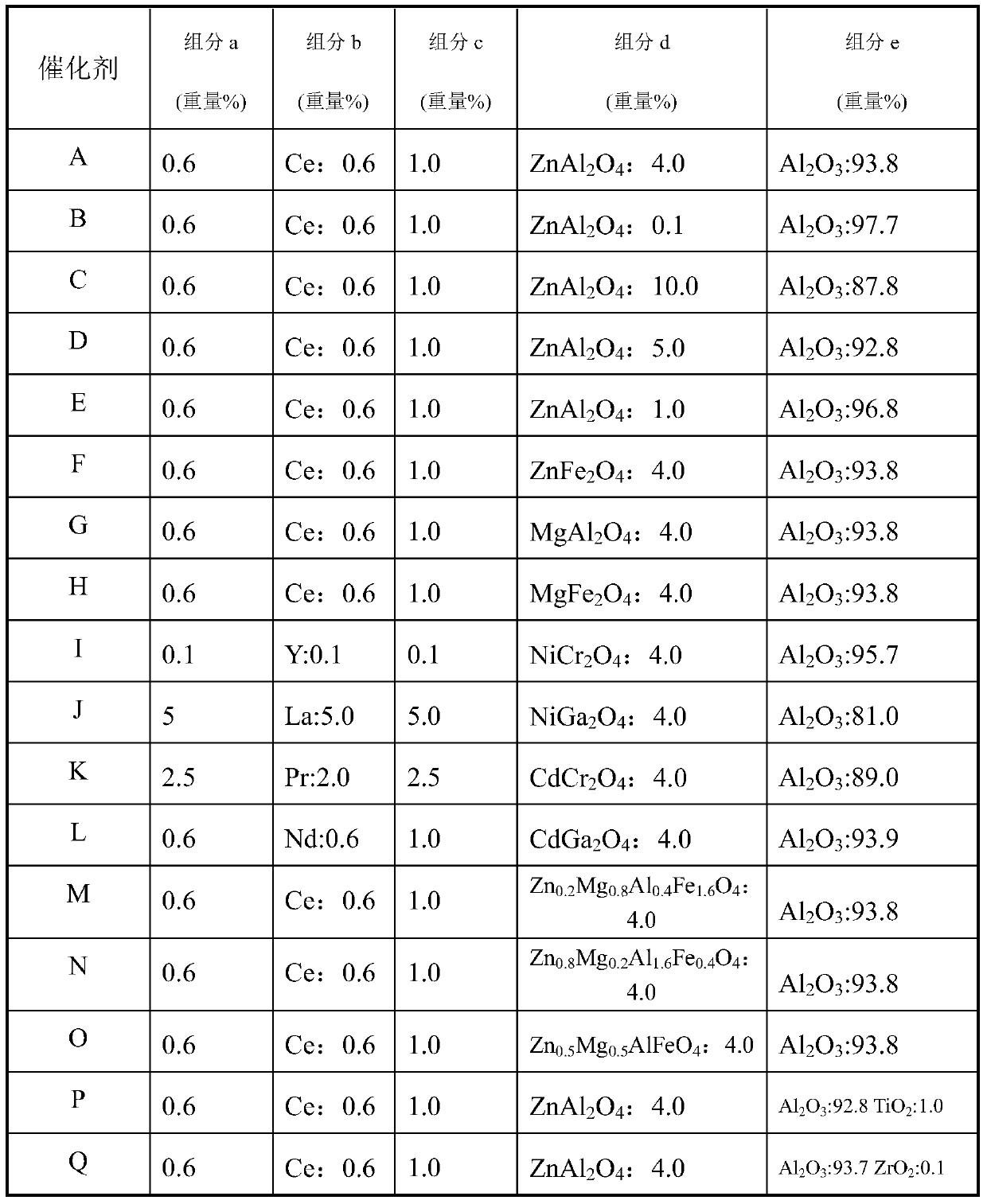

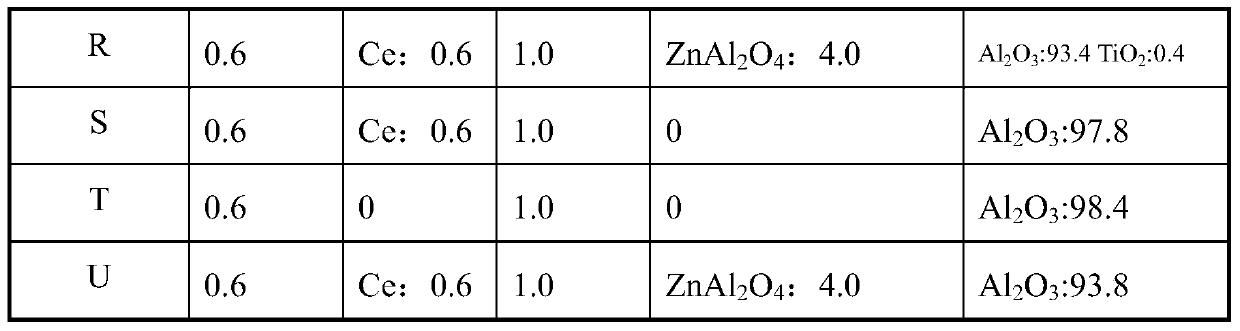

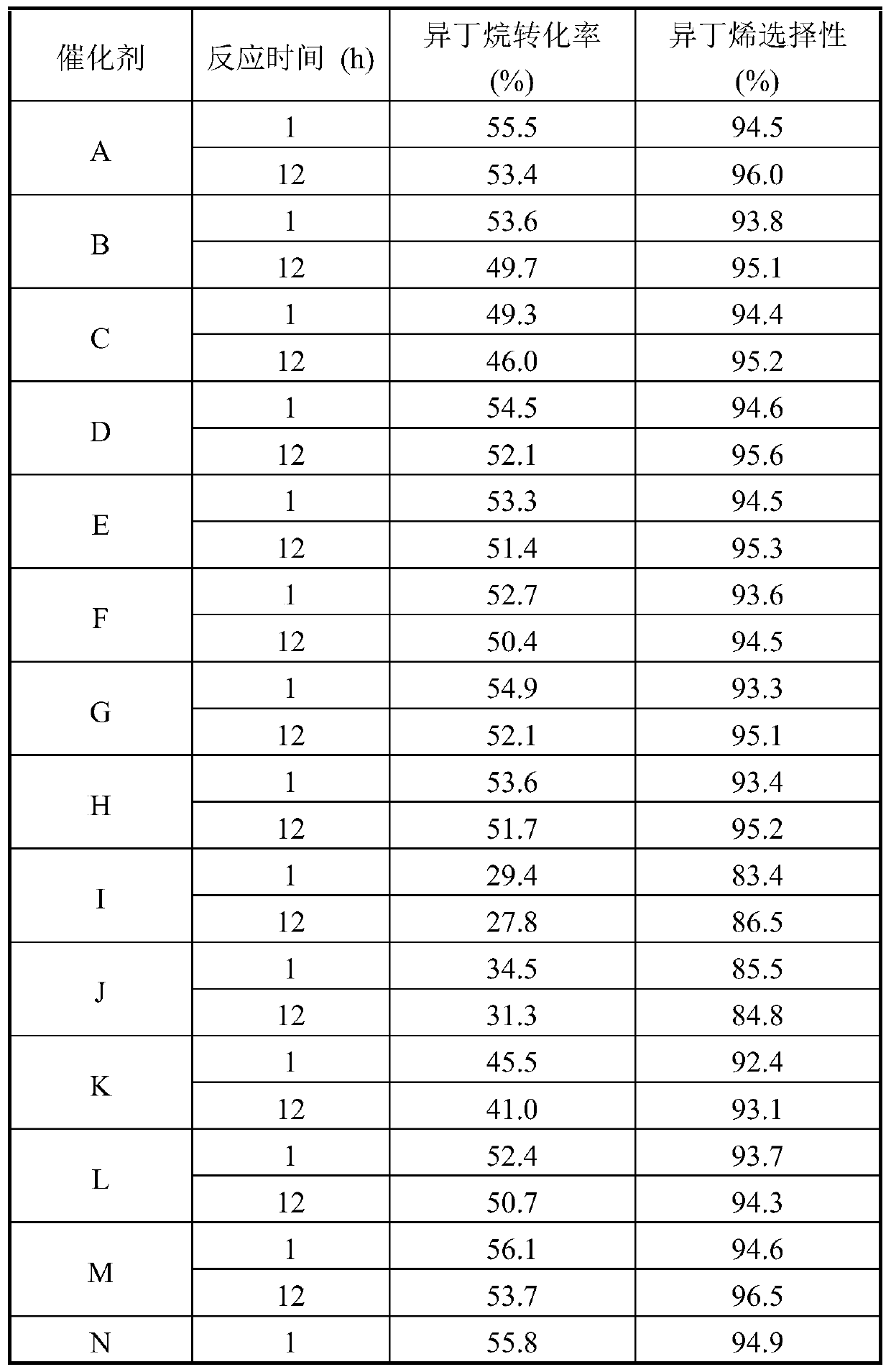

Examples

Embodiment 1

[0024] Weigh 9.38g of alumina carrier and pour it into 200mL of deionized water and stir for 1 hour, weigh 1.637g of aluminum nitrate and 0.649g of zinc nitrate and dissolve them in 50mL of deionized water respectively, then mix the two evenly, and pour alumina and water After continuing to stir for 1 hour, ammonia water was slowly added dropwise under continuous stirring until the pH was 8.5. Aging the product for 2 hours, filtering and washing with 2L of water to obtain a filter cake, drying the filter cake at 90°C for 16 hours, and then roasting it in a muffle furnace at 580°C for 20 hours to obtain ZnAl 2 o 4 -Al 2 o 3 carrier. Weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add it to the above-mentioned carrier under stirring, mix well, soak at 30°C for 12 hours, and then dry at 90°C for 16 hours to obtain the catalyst precursor, which is recorded as I. Weigh 0.159g of chloroplatinic acid and 0.186g of cerium nitrate and dissol...

Embodiment 2

[0026] Weigh 9.77g of alumina carrier and pour it into 200mL of deionized water and stir for 1 hour, weigh 0.041g of aluminum nitrate and 0.017g of zinc nitrate and dissolve them in 50mL of deionized water respectively, then mix the two evenly, pour alumina and water After continuing to stir for 1 hour, ammonia water was slowly added dropwise under continuous stirring until the pH was 8.5. Aging the product for 2 hours, filtering and washing with 2L of water to obtain a filter cake, drying the filter cake at 90°C for 16 hours, and then roasting it in a muffle furnace at 580°C for 20 hours to obtain ZnAl 2 o 4 -Al 2 o 3 carrier. Weigh 0.295g of tin tetrachloride and dissolve it in 10mL of hydrochloric acid solution, add it to the above-mentioned carrier under stirring, mix evenly, impregnate at 10°C for 24 hours, and then dry at 90°C for 16 hours to obtain the catalyst precursor, which is recorded as I. Weigh 0.159g of chloroplatinic acid and 0.186g of cerium nitrate and di...

Embodiment 3

[0028] Weigh 8.78g of alumina carrier and pour it into 200mL of deionized water and stir for 1 hour, weigh 4.093g of aluminum nitrate and 1.623g of zinc nitrate and dissolve them in 50mL of deionized water respectively, then mix the two evenly, pour alumina and water After continuing to stir for 1 hour, ammonia water was slowly added dropwise under continuous stirring until the pH was 8.5. Aging the product for 2 hours, filtering and washing with 2L of water to obtain a filter cake, drying the filter cake at 90°C for 16 hours, and then roasting it in a muffle furnace at 580°C for 20 hours to obtain ZnAl 2 o 4 -Al 2 o 3 carrier. Weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add it to the above-mentioned carrier under stirring, mix well, soak at 80°C for 1 hour, and then dry at 90°C for 16 hours to obtain the catalyst precursor, which is designated as I. Weigh 0.159g of chloroplatinic acid and 0.186g of cerium nitrate and dissolve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com