V-belt conveyor

A technology of V-belt and conveyor, applied in the direction of conveyor, transportation and packaging, can solve the problems of inconvenient installation and disassembly, bulky body, complex structure, etc., and achieve the effects of convenient installation, strong mobility and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

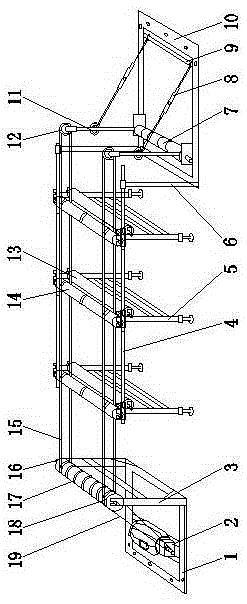

[0010] As shown in the figure, this case only takes the conveyor with two V-belts as an example. A pair of horizontally arranged headstocks 13 are installed on the flat-packed frame-shaped headstock 1. The upper end of the headstock 3 is equipped with a horizontal drive shaft. 16. A plurality of sheaves 17 are mounted on the upper row of the driving shaft 16, and one end of the driving shaft 16 is equipped with a power wheel 18. The power wheel 18 is connected with the power unit 2 by a transmission belt 19. The power unit 2 is installed on the headstock 1, and the sheave Conveying V-belt 15 is housed on 17, and the other end of V-belt 15 is equipped with driving wheel 12, and the conveying pole 11 that supports is housed on the driving wheel 12, and the horizontal width adjustment post 7 that width adjustment is housed at the lower end of conveying pole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap