Method for evaluating fold-crack resistance of coated paperboard

A coated cardboard, anti-folding technology, applied in the direction of using a stable bending force to test the strength of materials, measuring devices, and material analysis through optical means, can solve the problems of inability to achieve quantitative evaluation and large human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

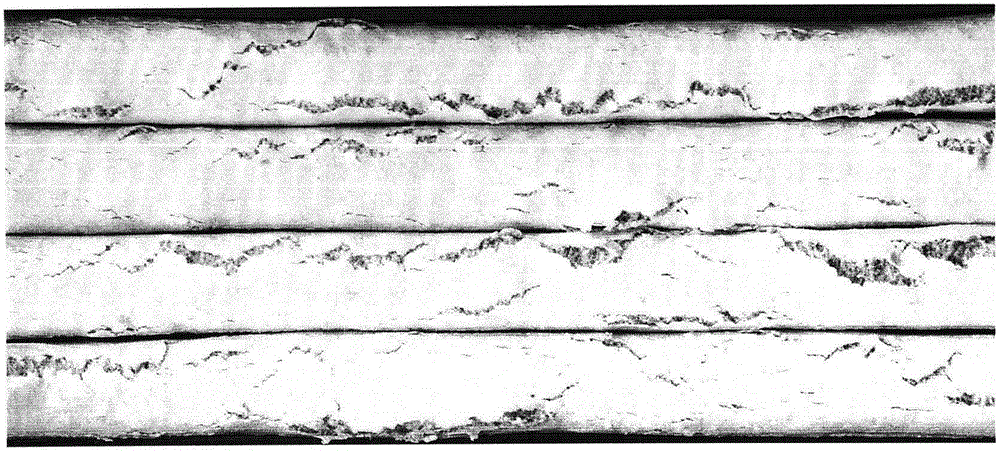

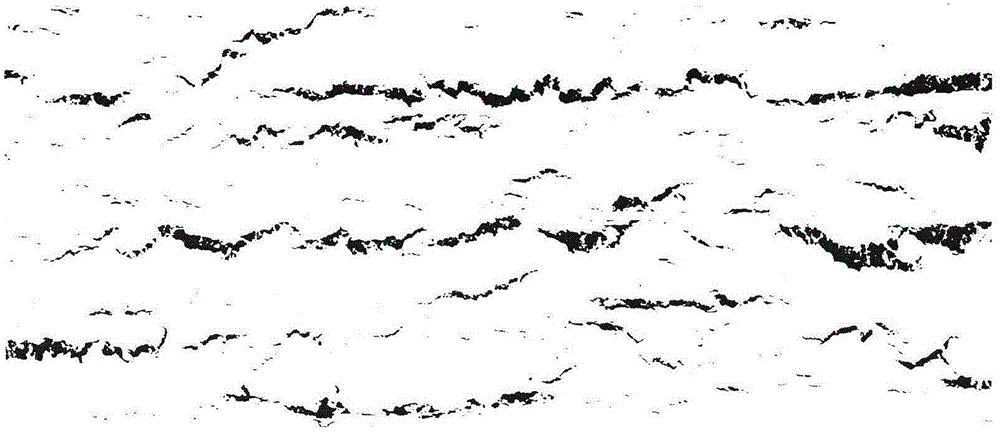

[0019] Select base paper weight 250g / m 2 , the coating weight is 45g / m 2 coated whiteboard. Folding along the transverse direction of the cardboard, the cardboard coating is first stretched and then compressed. The tension in the plane of the cardboard is 0.75kg during folding. Scan the crease of the folded coated white cardboard, the scanning resolution is 4800dip, and the scanned image is an 8-bit grayscale image, see the attached figure 1 . Using the ImageJ image processing software, the 8-bit grayscale image was binarized, and the background and edges were removed. The processed binary image is shown in the appendix. figure 2 . Use the Analyze Particles command of ImageJ image processing software to attach figure 2 The image of the image is analyzed, and the analysis result of Summarize gives the proportion of the coating crack area (Area Fraction), which is 5.4%.

Embodiment approach 2

[0021] Select base paper weight 200g / m 2 , coating amount is 25g / m 2 coated white cardboard. Folding along the transverse direction of the cardboard, the cardboard coating is first stretched and then compressed. The tension in the plane of the cardboard is 0.75kg during folding. Scan the crease of the folded coated white cardboard with a scanning resolution of 4800dip, and the scanned image is an 8-bit grayscale image. Using ImageJ image processing software, the 8-bit grayscale image was binarized and the background and edges were removed. The image was analyzed using the Analyze Particles command of the ImageJ image processing software, and the analysis result of Summarize gave the ratio of the coating crack area (Area Fraction), which was 2.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com