Novel spray side wall modular integration device

An integrated device and modular technology, which is applied in the direction of spraying devices, spray booths, and devices for coating liquid on the surface, etc., can solve the problems of difficult operation risks for installers, increase maintenance difficulty and cost, affect installation quality and installation efficiency, etc. , to achieve the effect of shortening maintenance and repair time, improving installation quality and installation efficiency, and shortening time for high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

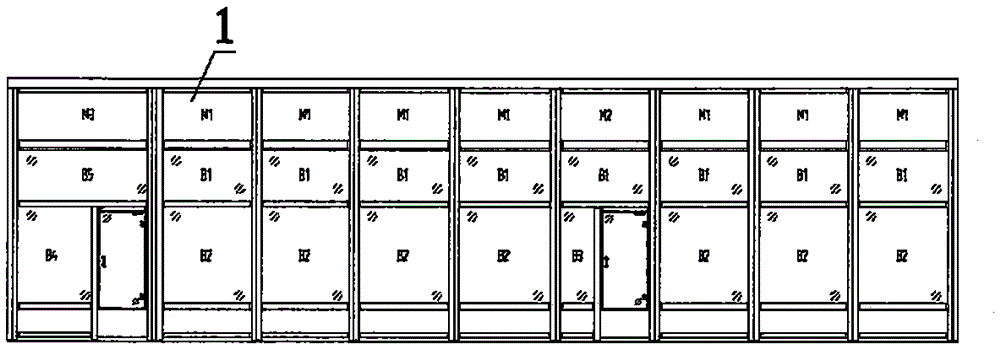

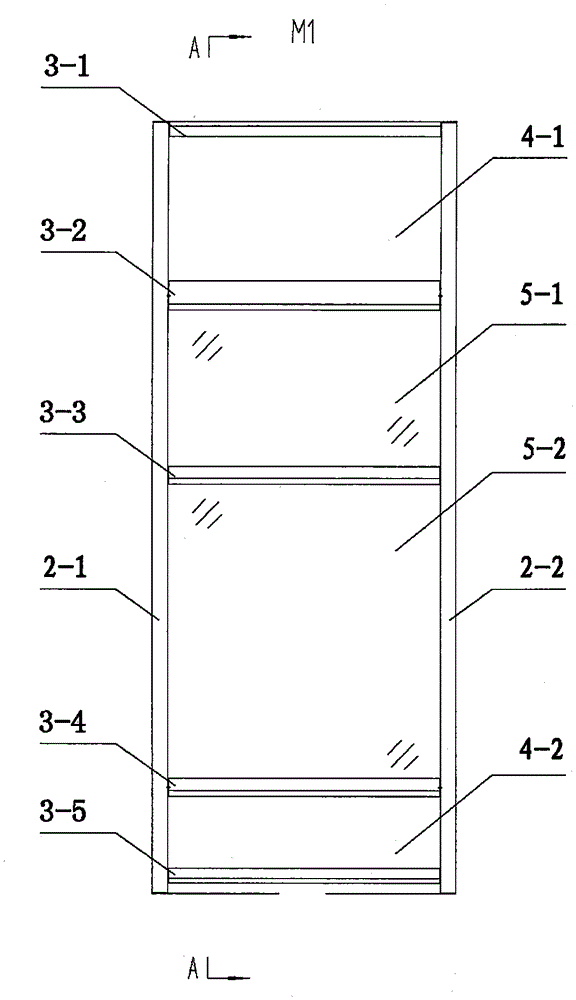

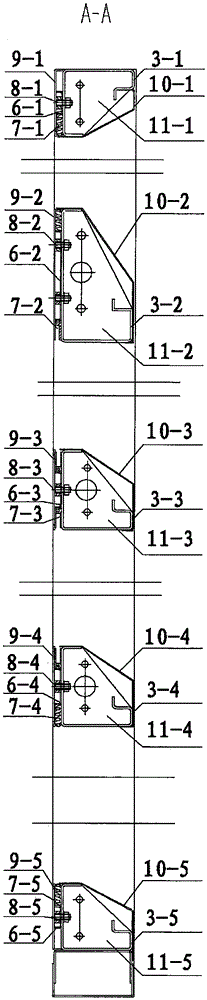

[0012] exist figure 1 , figure 2 , image 3 Among them, a single module 1 is in the shape of a rectangle, which is welded by two columns 2 and five beams 3, that is, columns 2 are arranged on both sides, and five beams 3-the first beam 3- are arranged between the columns 2 from top to bottom. 1. The second beam 3-2, the third beam 3-3, the fourth beam 3-4, and the fifth beam 3-5, wherein the first beam 3-1 and the fifth beam 3-5 are respectively connected with the two columns 2 The two ends are welded and fixed, between the first crossbeam 3-1, the second crossbeam 3-2 and the fourth crossbeam 3-4, the fifth crossbeam 3-5 is provided with a vertical plate 4, the vertical plate 4 and the crossbeam 3 Fixed by welding, a vertical glass plate 5 is arranged between the second beam 3-2, the third beam 3-3 and the third beam 3-3, the fourth beam 3-4, the vertical glass plate 5 and the beam 3 The following devices are used to connect and fix: place the U-shaped positioning plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com