Novel overturning structure

A technology of flipping structure and flipping mechanism, which is applied to auxiliary devices, vehicle parts, auxiliary welding equipment, etc., can solve the problems of inability to meet workpiece flipping, high manufacturing cost, and inability to flip, so as to reduce the configuration of flipping machines and reduce transportation operations. Process, flexible combination of convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

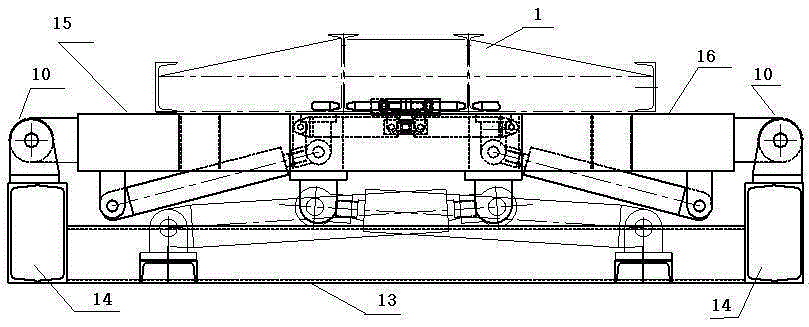

[0024] see figure 1 As shown, the present invention includes a left turning mechanism 15, a right turning mechanism 16 and an underframe 13, the workpiece 1 is clamped on the left turning mechanism 15, the rotating shaft 10 is fixed on the rotating shaft base 14, and the rotating shaft base 14 is tightly Be fixed in the chassis 13.

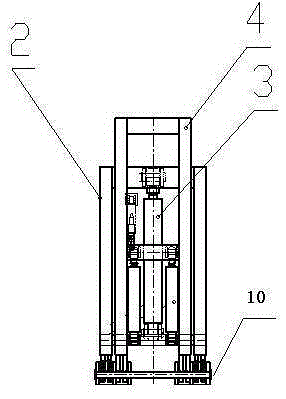

[0025] see figure 2 As shown, in the turning mechanism of the present invention, the large suspension 2 is driven to and fro by the large suspension driving cylinder 3, and the small suspension 4 and the large suspension 2 share a rotating shaft 10.

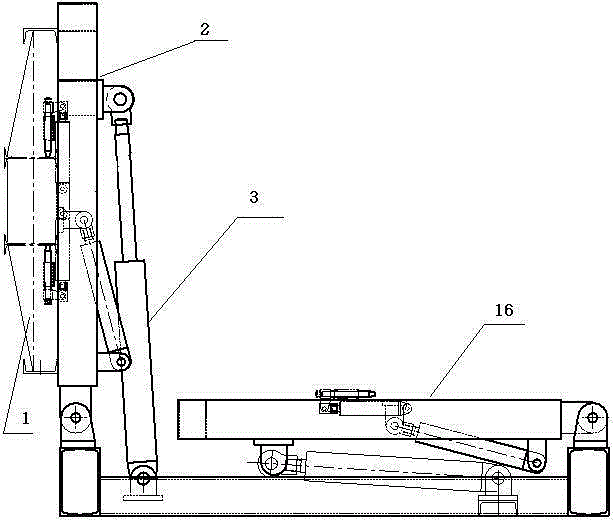

[0026] see image 3 As shown, the left turning mechanism 15 of the present invention has turned over 90 °. At this time, the large suspension drive cylinder 3 ejects the large suspension 2, so that the workpiece 1 clamped on the small suspension 4 has tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com