Transferring and loading platform flexible clamp positioning device

A technology of flexible fixtures and positioning devices, applied in auxiliary devices, manufacturing tools, transportation and packaging, etc., can solve the problems of difficult switching of fixture positioning pins and low positioning accuracy, and achieve simple structure, improved positioning accuracy, fast movement and guidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

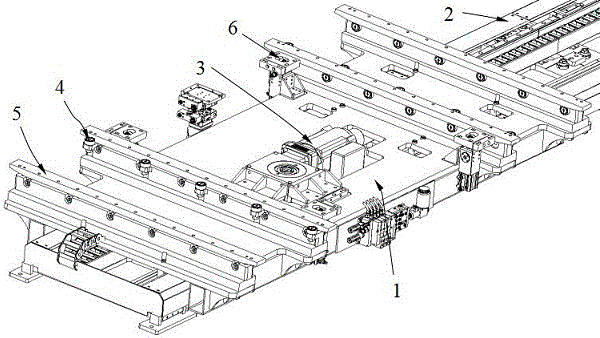

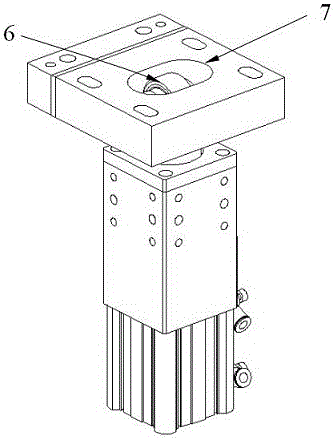

[0014] see figure 1 and figure 2 As shown, a flexible fixture positioning device for a transfer platform is adopted, including a transfer platform 1, a track 2, a motor 3, a guide roller 4, a guide plate 5, a roller pin 6, a long waist hole 7, etc., wherein the transfer platform The carrying platform 1 is equipped with multiple groups of guide plates 5, the length of which is greater than the width of the transfer platform 1; the guide rollers 4 are installed on one side of the guide plate 5, and are evenly arranged along the length direction of the guide plate 5; the long waist holes are installed on The bottom of the flexible clamp is the positioning hole of the clamp; the roller pins 6 are symmetrically arranged on the opposite corners of the transfer platform; Waist hole 7 clearance fit.

[0015] see figure 1 As shown, the transfer platform 1 can move forward and backward along the direction of the track 2. The track 2 is provided with a rack and pinion, and the gear i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com