Titanium alloy polyhedron rudder frame and preparation method thereof

A processing method and titanium alloy technology, applied in the field of titanium alloy thin polyhedral rudder frame and its processing, can solve the problems of low processing efficiency and poor stability, and achieve the effect of improving processing efficiency, high accuracy and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the spirit and essence of the present invention will be further elaborated in conjunction with the drawings and embodiments.

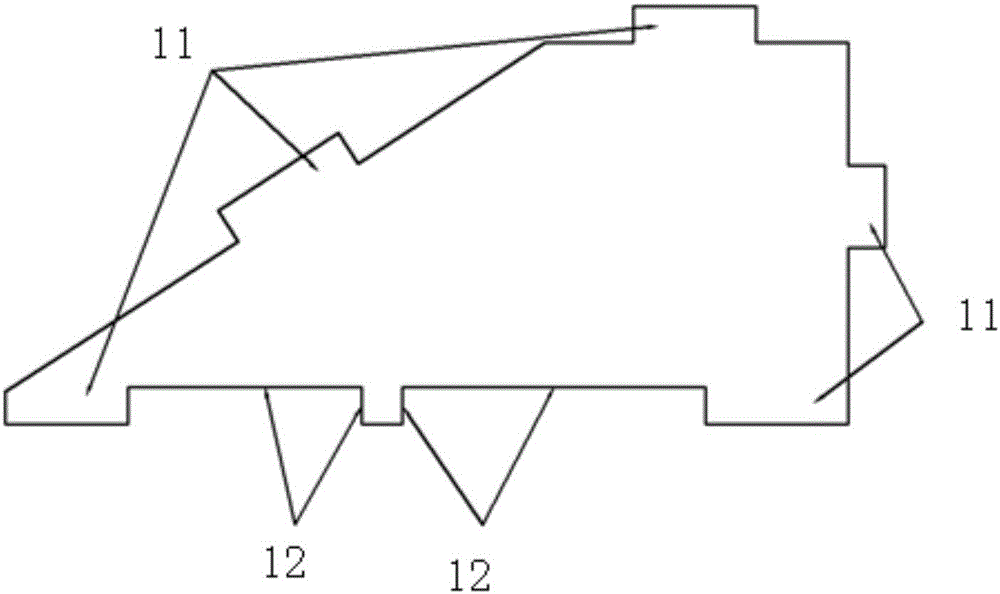

[0048] Such as figure 1 As shown, the reserved schematic diagram of the rudder skeleton craft block. Its material is Ti6Al4V titanium alloy plate, the maximum size of the contour of the part after three-axis CNC milling is 412x240xδ20mm, the protruding contour width of the process block 11 is 18mm, and the thickness of the process block is consistent with the part. The bottom surface of the part and both sides of the process block in the middle of the bottom are finely milled as the positioning datum surface 12 for subsequent processing. The bottom surface of the inclined surface is rectangular, and the bottom surface of the front edge inclined surface is triangular.

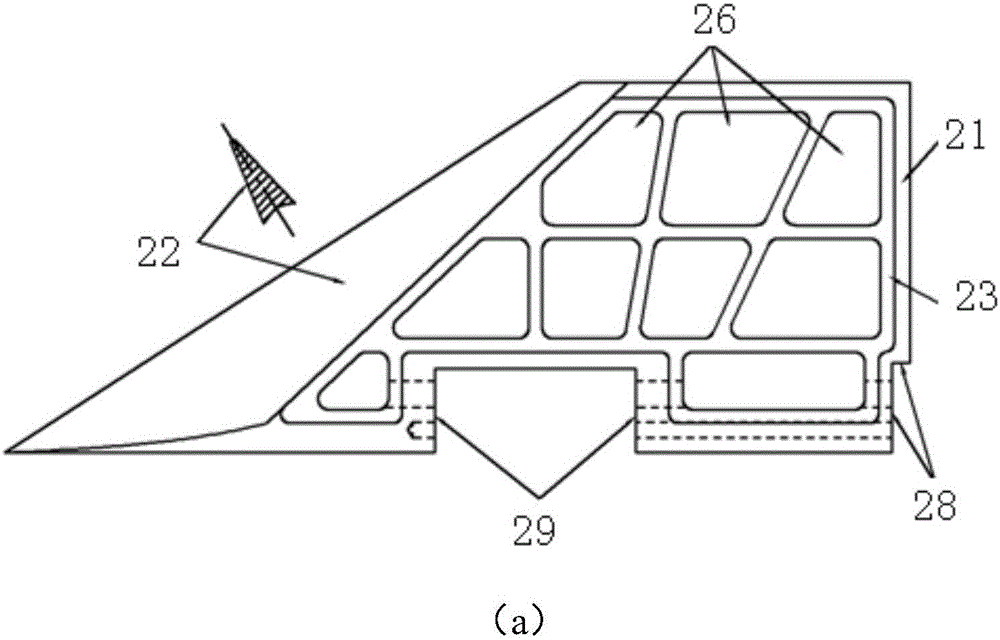

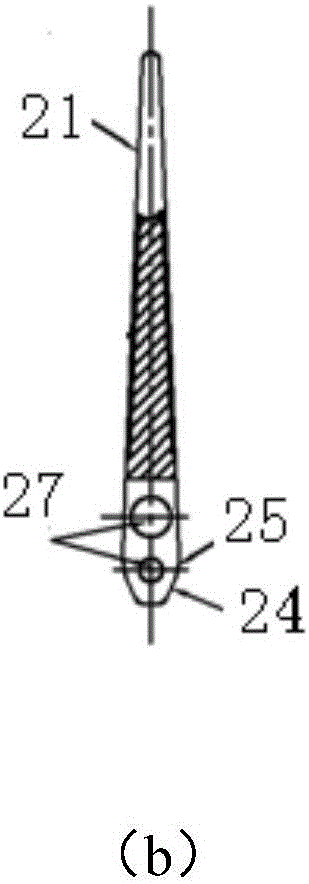

[0049] Such as figure 2 (a), the section of the titanium alloy thin polyhedron rudder frame provided by the embodiment of the present invention is a right-angled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com