Automatic pneumatic hammer device for pipe pile mould closing

A mold and pipe pile technology is applied in the field of detection devices for pipe pile molds, which can solve the problems of time-consuming and laborious bolts, inability to apply pipe pile molds, and inability to achieve automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

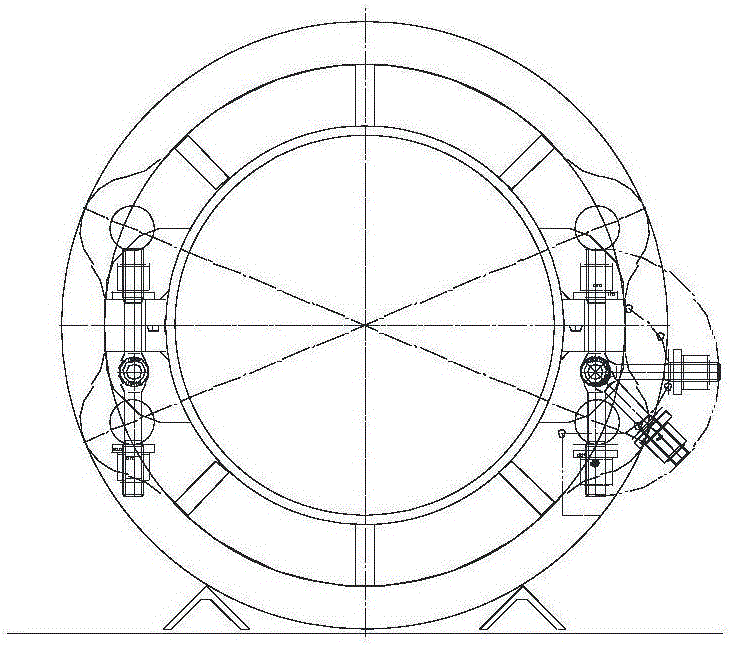

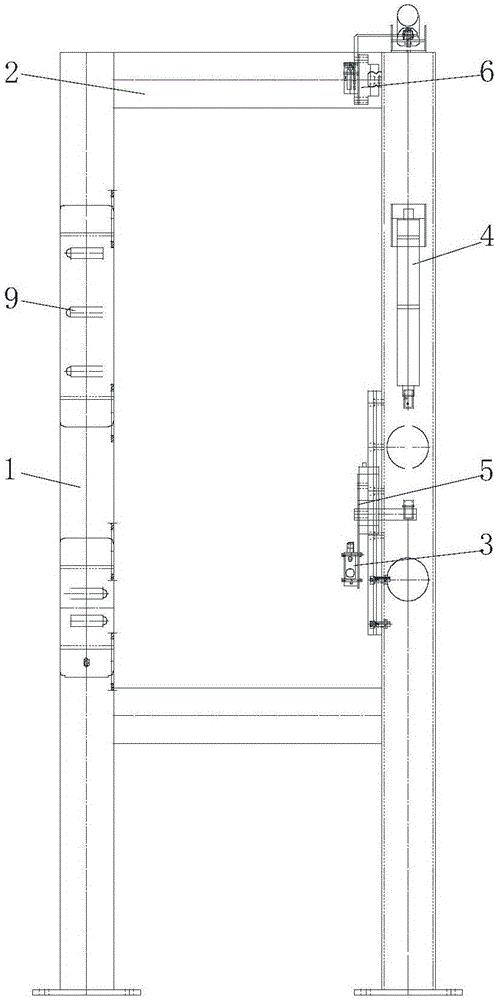

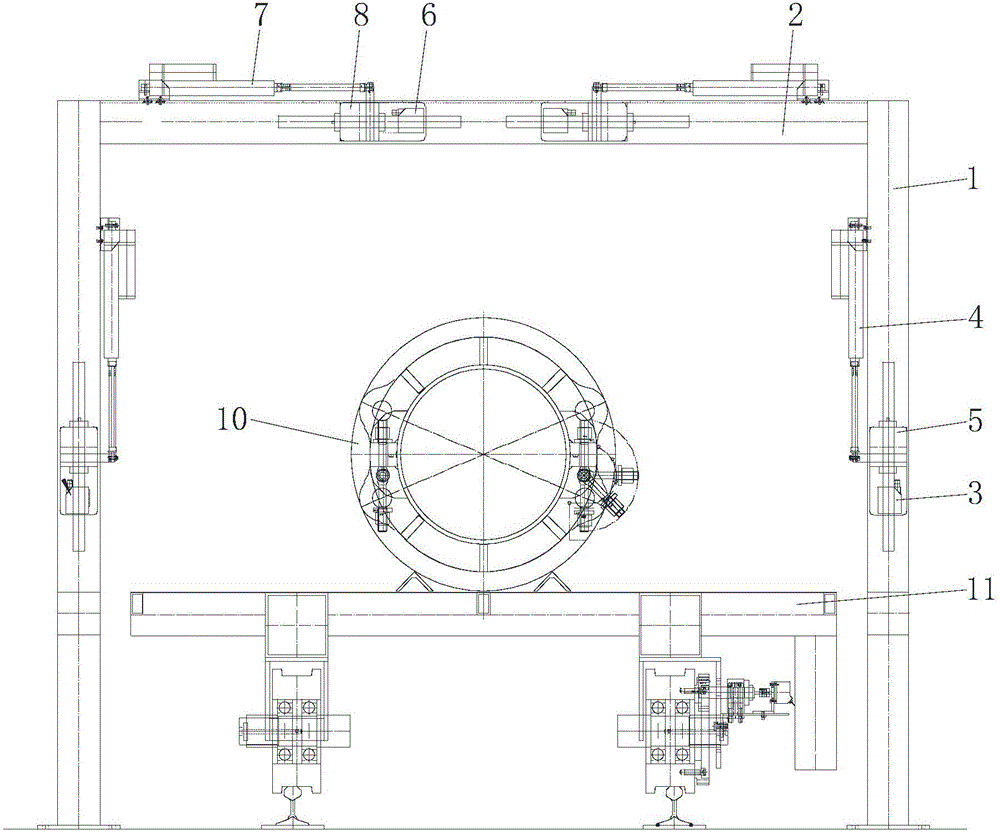

[0031] Such as Figure 3 to Figure 7 As shown, the automatic wind gun device for pipe pile mold clamping includes a detection device, a first frame for the pipe pile mold to pass through, a first linear drive mechanism, a second frame, a platform, a third frame, a first The lifting drive mechanism, the wind gun mechanism, the second linear drive mechanism, and the rotating mechanism that rotates the bolts hinged on the pipe pile mold, each part and the relationship between them are described in detail below:

[0032] The detection device is located upstream of the first frame. The detection device detects each notch on the pipe pile mold and the specific position of each bolt. The detection device includes:

[0033] Such as image 3 and Figure 4 As shown, the frame passing through the pipe pile mold 10; the frame is made up of at least two longitudinal beams 1 and at least one crossbeam 2, and the end of the longitudinal beam 1 is connected with the end of the crossbeam 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com