Drilling clamp for special-shaped bent pipes

A drilling fixture and pipe bending technology, which is applied in the field of drilling fixtures for special-shaped pipe bends, can solve the problems of easy damage to the surface of special-shaped pipe bends, deviation of hole positions on special-shaped pipe bends, and easy deformation of special-shaped pipe bends. Achieve the effect of uniform force, reduced production cost and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

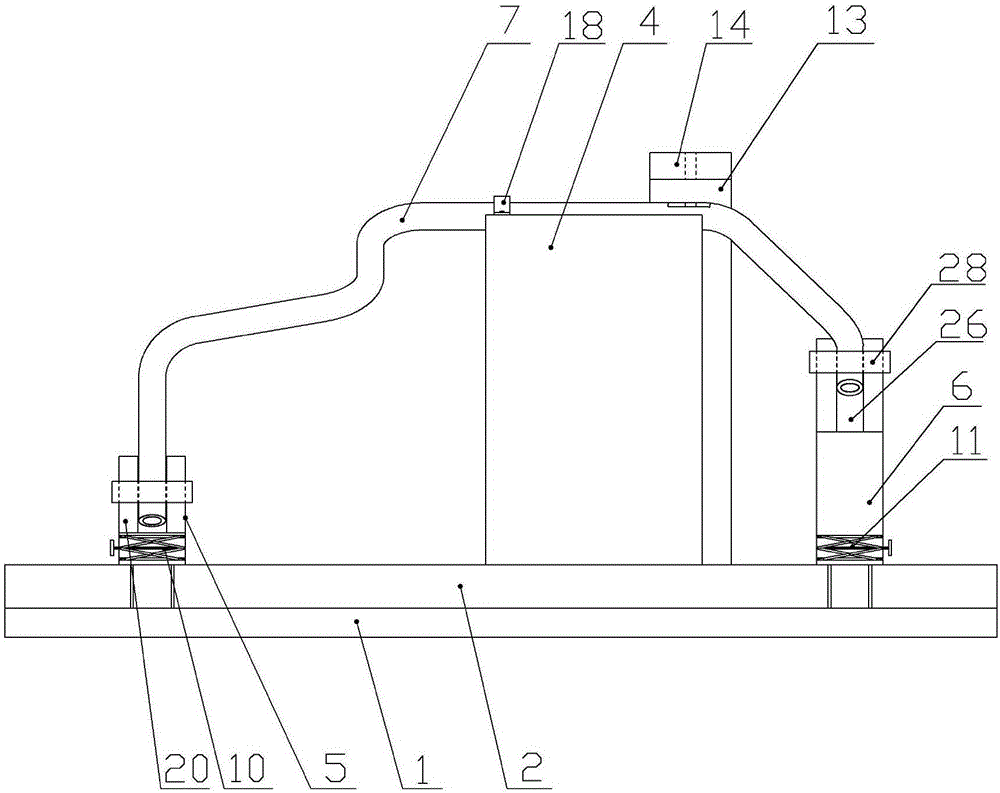

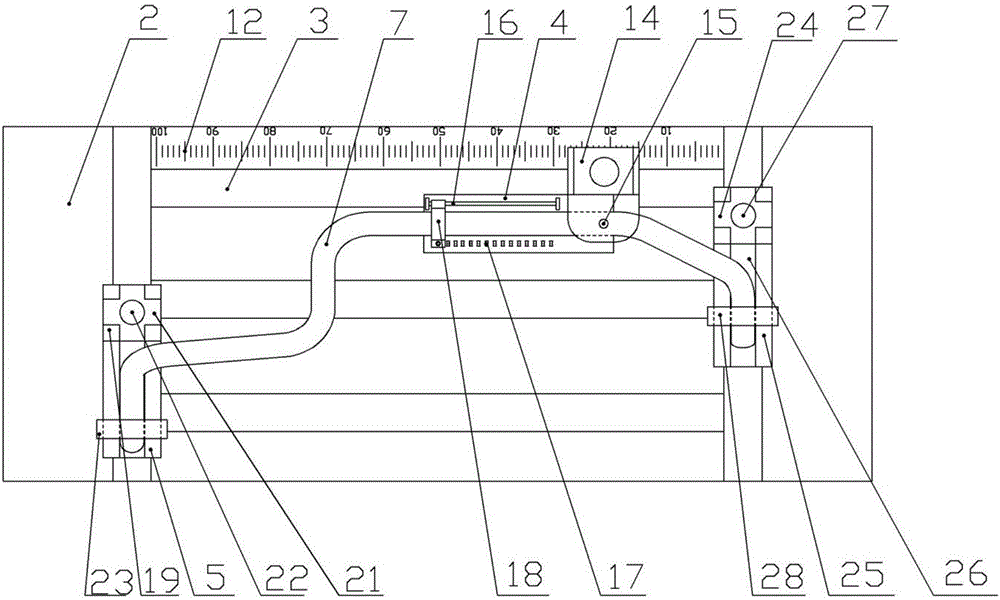

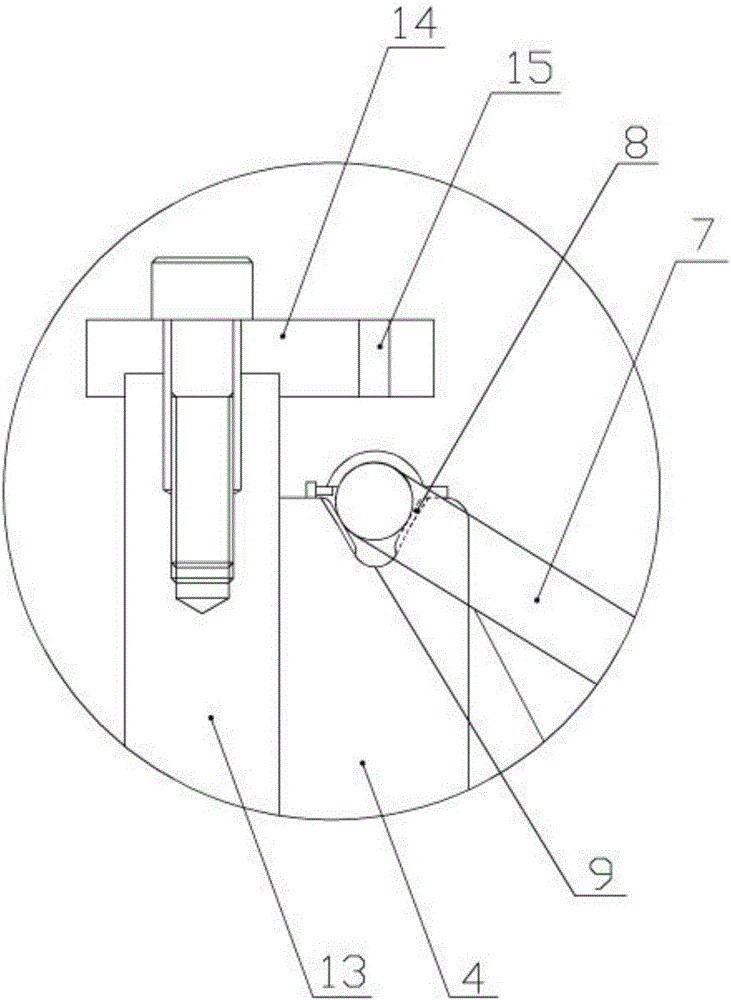

[0022] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Refer to the attached figure 1 , 2 , the present invention comprises a base 1, the base 1 is provided with a mounting plate 2, a plurality of crisscross chute 3 is provided on the mounting plate 2, and a supporting platform 4, a first fixing platform 5 and a second fixing platform 5 are installed on the mounting plate 2 Platform 6, the first fixed platform 5 and the second fixed platform 6 are respectively positioned at the both sides of supporting platform 4; 6 respectively fix the two ends of the special-shaped elbow;

[0024] The bottom end of support table 4 is installed in a chute 3 by the first slide mechanism, and the first slide mechanism is a slide block, and the support table 4 is fixed with drilling mechanism, and the drilling mechanism is used for the position and position of the elbow drilling. The size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com