Automatic dust-free hinge hole numerical control machine

A hinge hole and CNC machine technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of low precision, low efficiency of drilling methods, etc., to improve efficiency, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

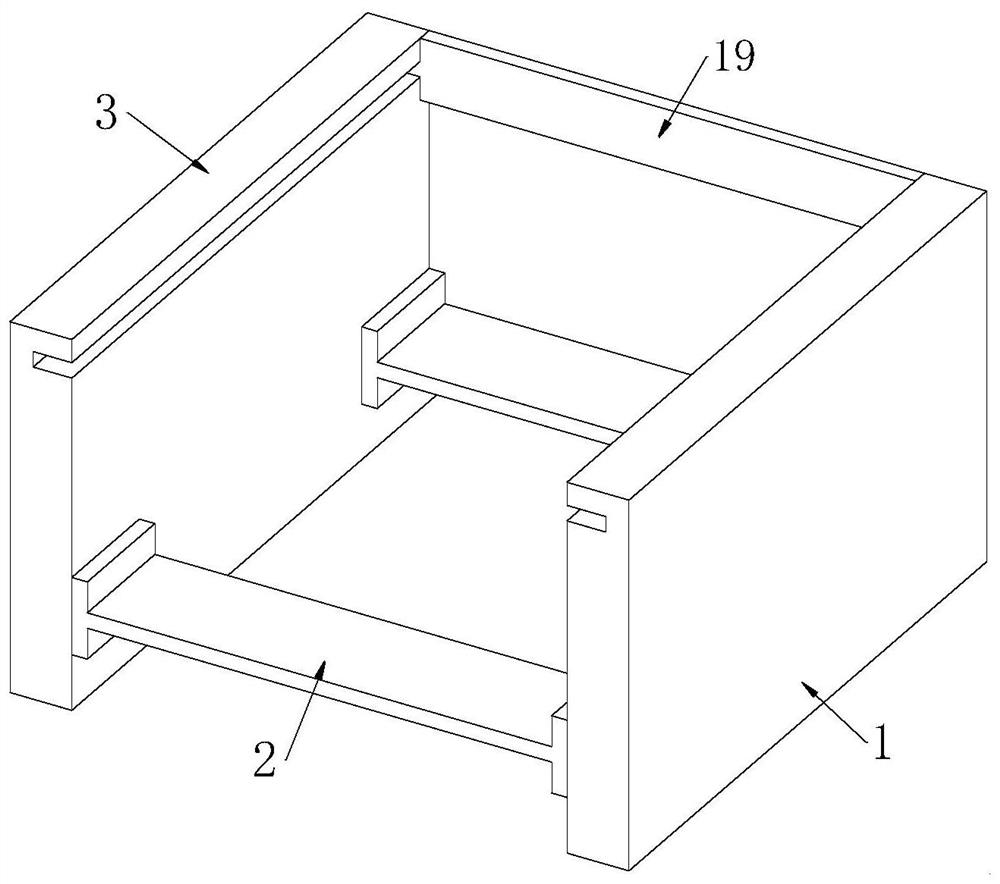

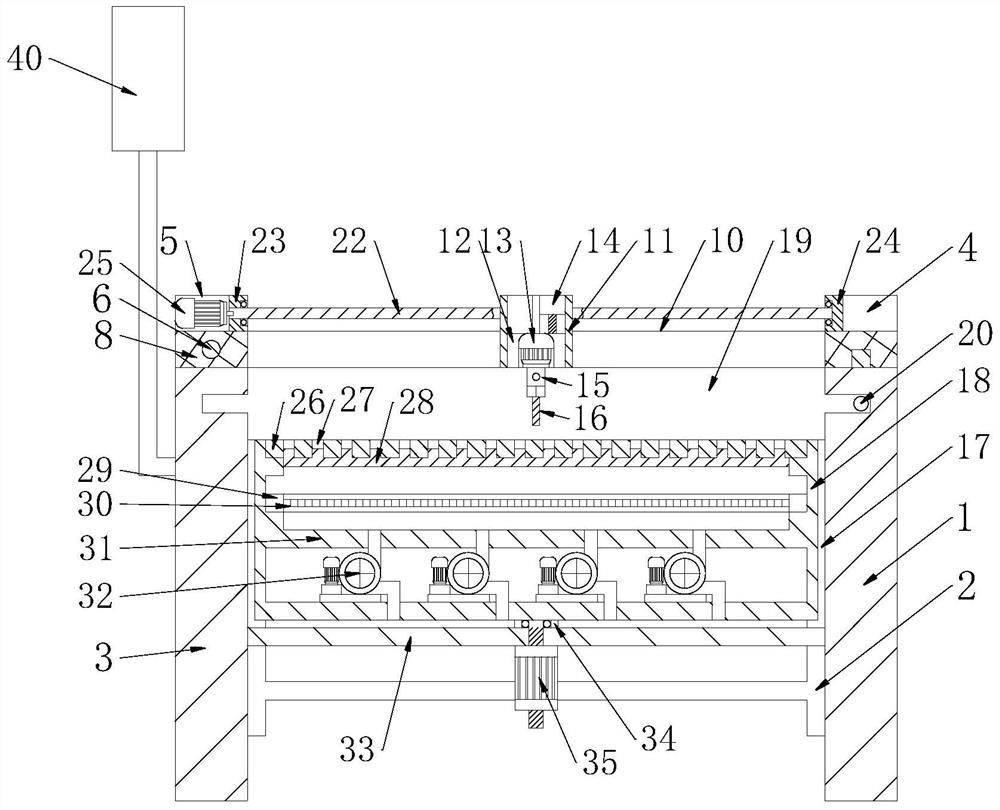

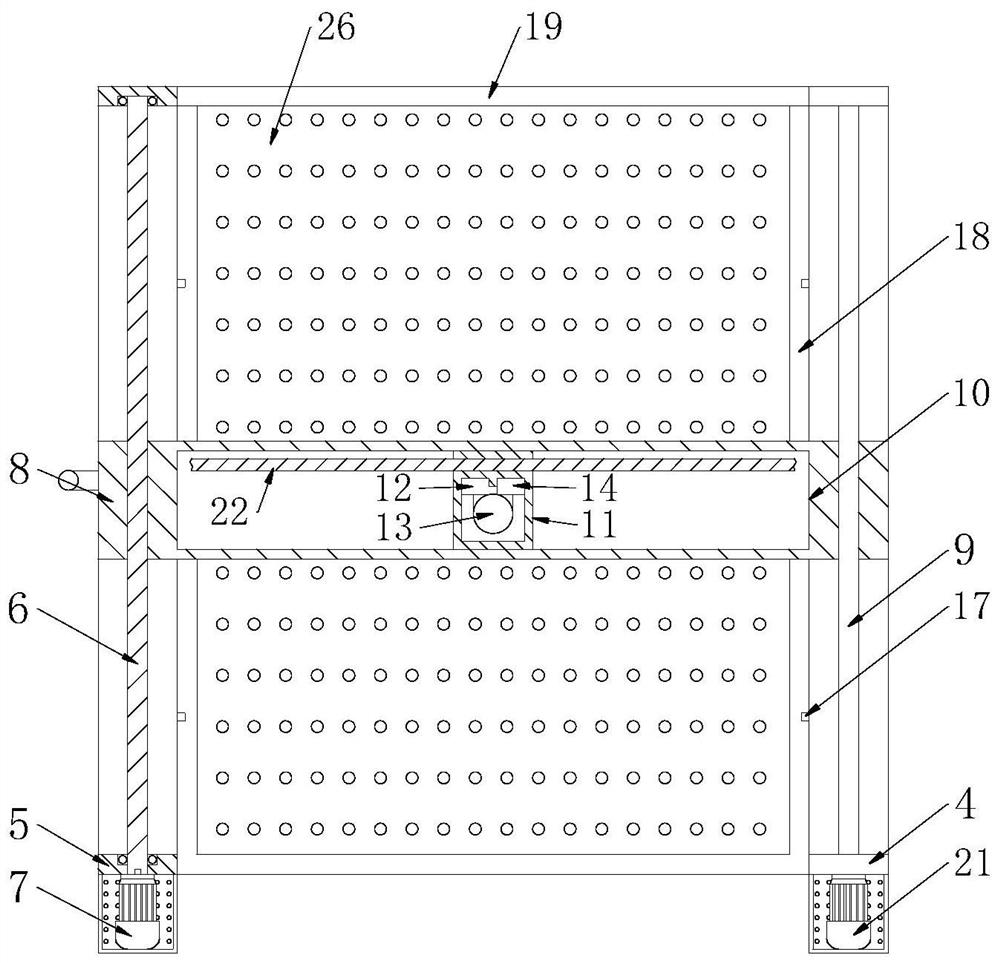

[0031] see Figure 1-4 As shown, an automatic dust-free hinge hole CNC machine includes a first bracket 1, a connecting plate 2, a second bracket 3 and a high-precision positioning unit; the two ends of the connecting plate 2 are symmetrically fixed with the first bracket 1 and the The second bracket 3; the first bracket 1 and the second bracket 3 are provided with a high-precision positioning unit;

[0032]The high-precision positioning unit includes a first end plate 4, a second end plate 5 and a first screw rod 6; the first end plate 4 is symmetrically fixed at both ends of the first bracket 1; the second end plate 5 are symmetrically fixed at both ends of the second bracket 3; a slide rail 9 is fixedly connected between the second bracket 3; a slider plate 8 is buckled and connected to the slide rail 9; inside the slider plate 8 The opening is threadedly connected with a first screw mandrel 6; the first screw mandrel 6 is rotatably connected between the second end plates ...

Embodiment 2

[0043] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, the lower surfaces of the first bracket 1 and the second bracket 3 are fixed with a plurality of universal wheels 37; the first bracket 1 and the A handle 38 is affixed to the side of the second support 3; a plurality of hanging shafts 39 are affixed vertically on the handle 38; during work, through a plurality of universal wheels 37, it is convenient to move this numerical control machine, and it is convenient to use by the handle 38 And carry this numerical control machine, hang and hold and use other articles of this numerical control machine conveniently by hanging shaft 39.

[0044] The working principle is to program the furniture parts of different shapes through the control panel 40. After the programming is completed, put the furniture parts to be drilled on the collecting plate 26, align one end with the reset plate 19, and fix the furniture parts on the In the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com