Sound insulation noise lowering type glass drilling machine

A drilling machine, glass technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve problems such as affecting user operation, high noise, coolant splash, etc., to reduce noise pollution, prevent splash, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

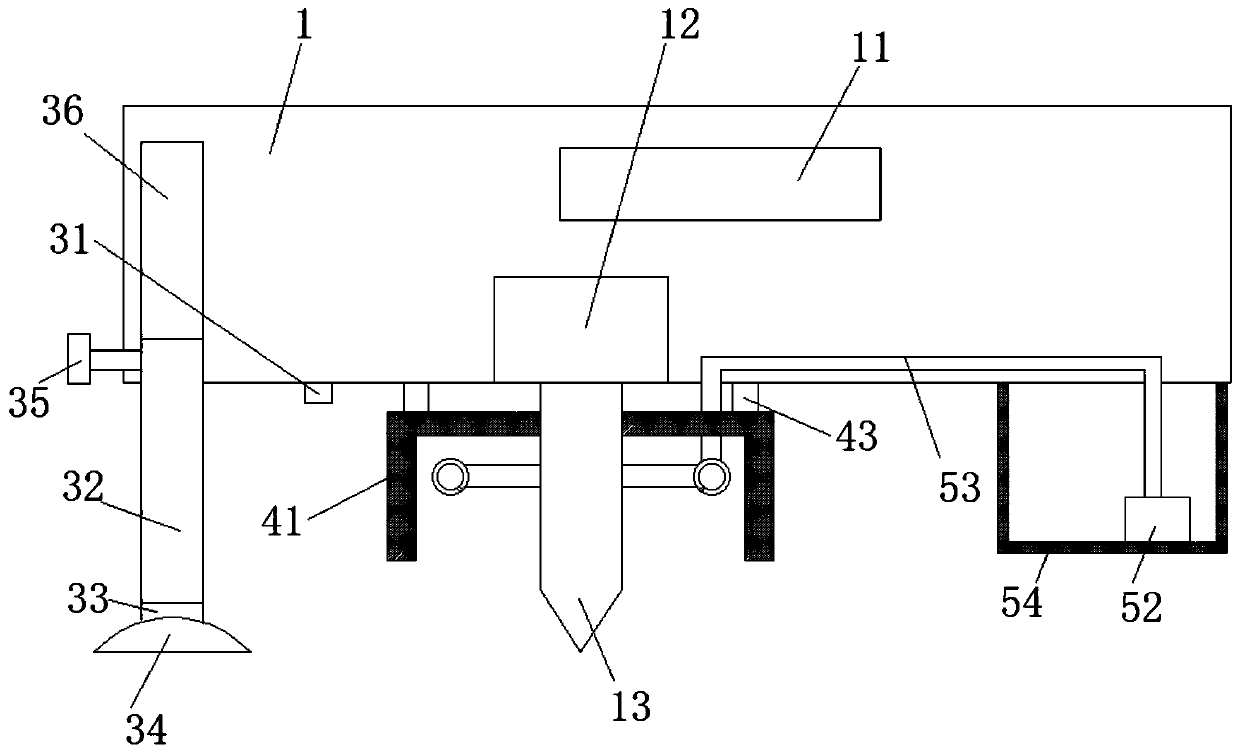

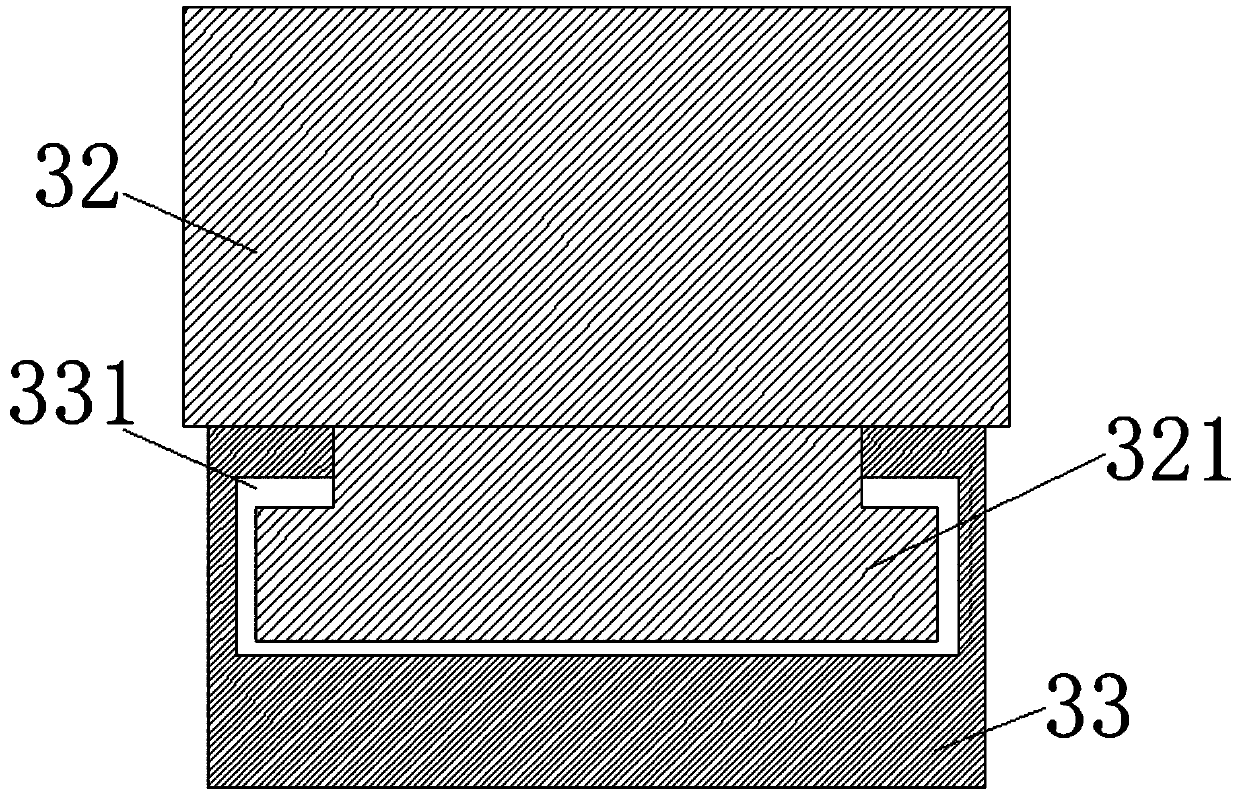

[0033] see Figure 1-2 , a sound-proof and noise-reducing glass drilling machine, comprising a drilling machine main body 1, a drilling motor 12 is provided at the bottom of the drilling machine main body 1, and a matching drill bit 13 is provided at the output end of the drilling motor 12, The bottom of the drilling machine main body 1 is provided with a drilling cover 41, the drill bit 13 passes through the middle part of the drilling cover 41, and the drilling cover 41 outside the drill bit 13 is provided with an annular spray pipe 51 for cooling. The main body of the drilling machine 1 is provided with a cooling tank 54, the cooling liquid is stored in the cooling tank 54, and the cooling tank 54 is provided with a cooling pump 52, and the output end of the cooling pump 52 is provided with a connecting pipe 53 , the connecting pipe 53 communicates with the annular spray pipe 51, and one end of the bottom of the drilling machine main body 1 is provided with a positioning ro...

Embodiment 2

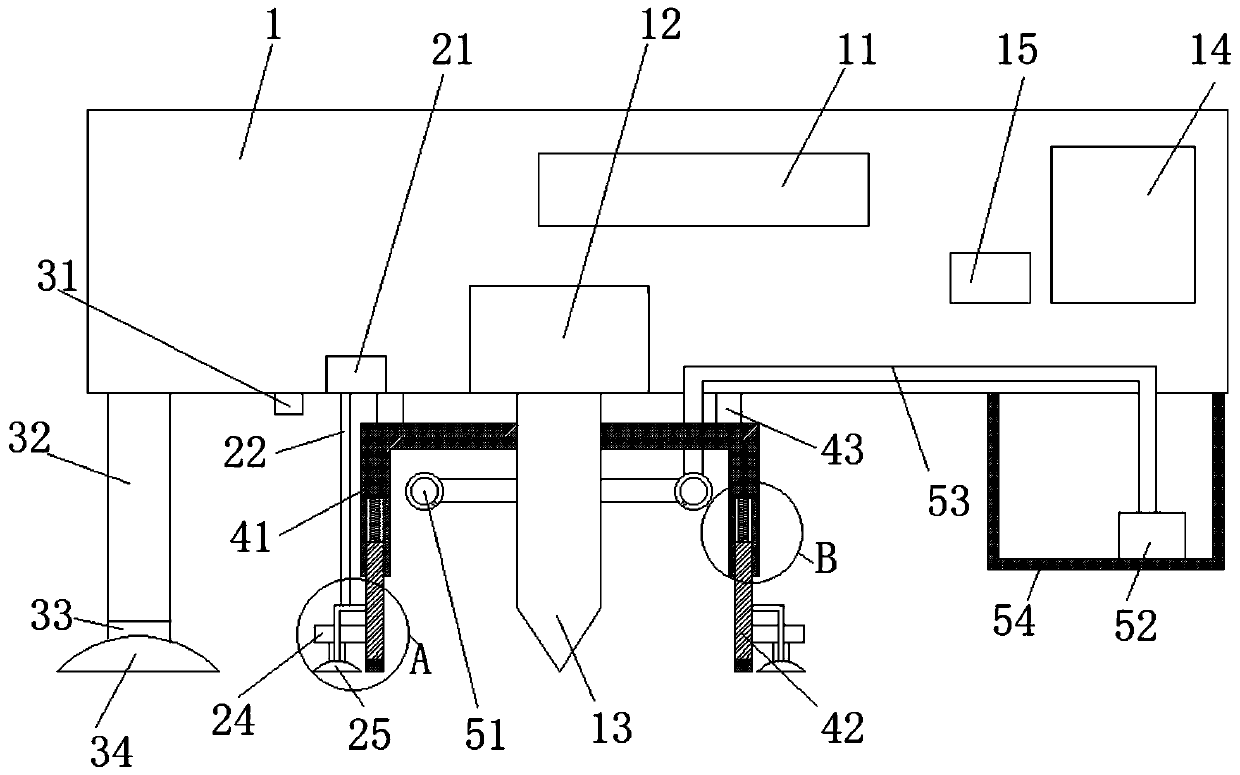

[0048] see Figure 3-5 , a sound-proof and noise-reducing glass drilling machine, comprising a drilling machine main body 1, a drilling motor 12 is provided at the bottom of the drilling machine main body 1, and a matching drill bit 13 is provided at the output end of the drilling motor 12, The bottom of the drilling machine main body 1 is provided with a drilling cover 41, the drill bit 13 passes through the middle part of the drilling cover 41, and the drilling cover 41 outside the drill bit 13 is provided with an annular spray pipe 51 for cooling. The main body of the drilling machine 1 is provided with a cooling tank 54, the cooling liquid is stored in the cooling tank 54, and the cooling tank 54 is provided with a cooling pump 52, and the output end of the cooling pump 52 is provided with a connecting pipe 53 , the connecting pipe 53 communicates with the annular spray pipe 51, and one end of the bottom of the drilling machine main body 1 is provided with a positioning ro...

Embodiment 3

[0062] see Figure 6-7 , a sound-proof and noise-reducing glass drilling machine, comprising a drilling machine main body 1, a drilling motor 12 is provided at the bottom of the drilling machine main body 1, and a matching drill bit 13 is provided at the output end of the drilling motor 12, The bottom of the drilling machine main body 1 is provided with a drilling cover 41, the drill bit 13 passes through the middle part of the drilling cover 41, and the drilling cover 41 outside the drill bit 13 is provided with an annular spray pipe 51 for cooling. The main body of the drilling machine 1 is provided with a cooling tank 54, the cooling liquid is stored in the cooling tank 54, and the cooling tank 54 is provided with a cooling pump 52, and the output end of the cooling pump 52 is provided with a connecting pipe 53 , the connecting pipe 53 communicates with the annular spray pipe 51, and one end of the bottom of the drilling machine main body 1 is provided with a positioning ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com