Micro injection molding machine with injection at right angles to the plasticizing axis

A right-angle, injection molding machine technology, applied in the field of plastic processing equipment, can solve problems such as bulky and complex structures, and achieve the effects of simplified support structure, simple transmission structure, and reduced axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

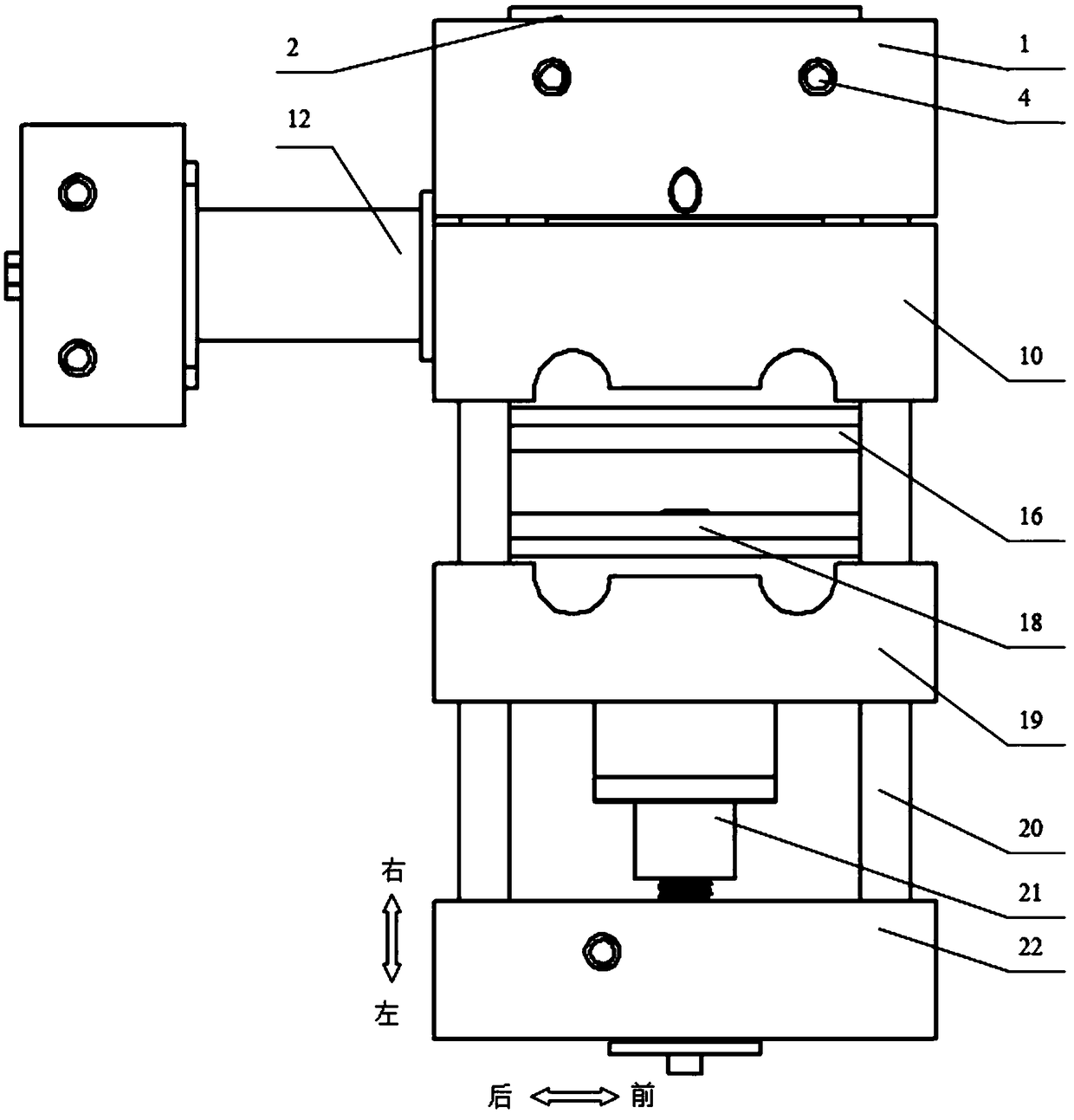

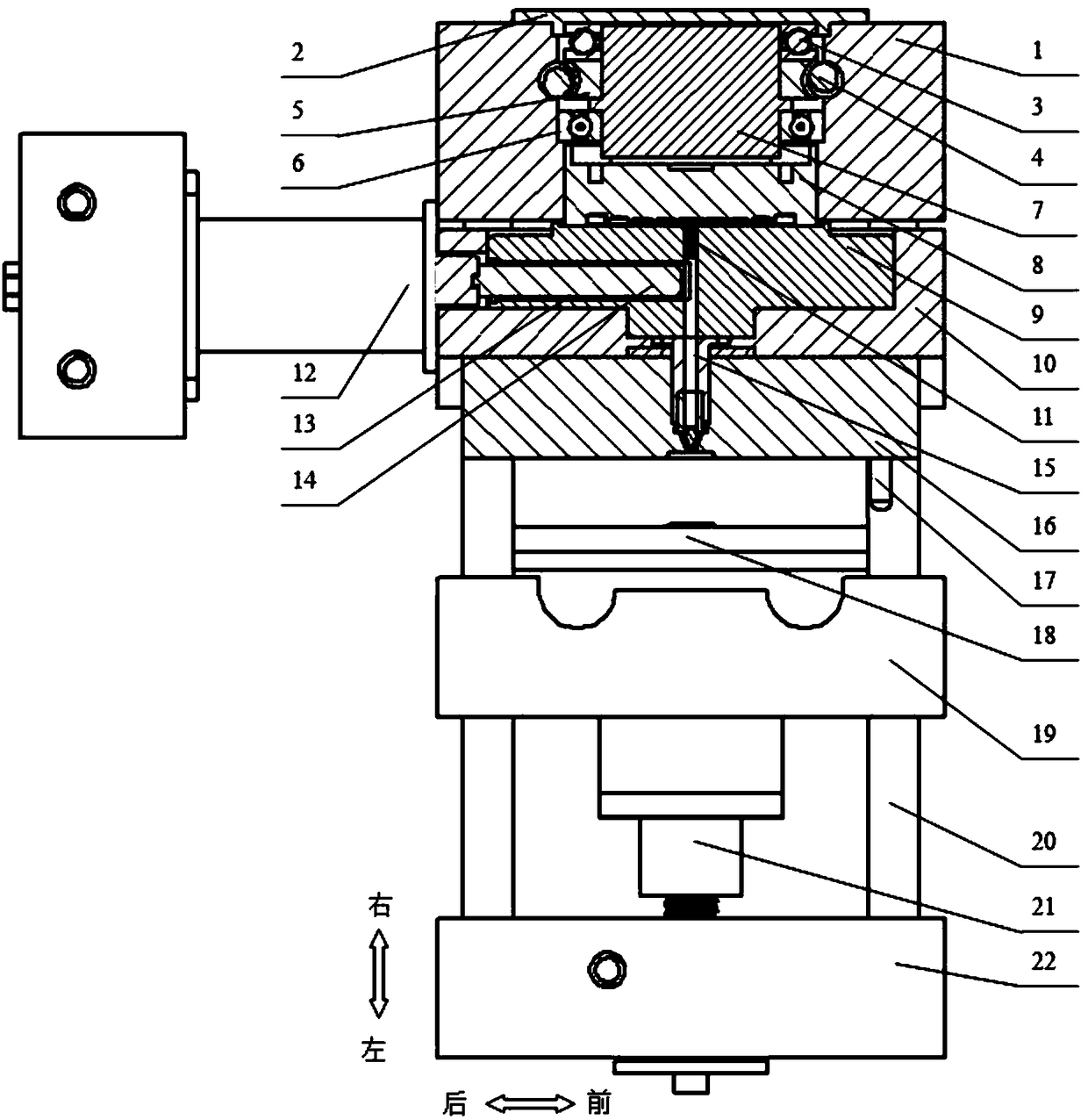

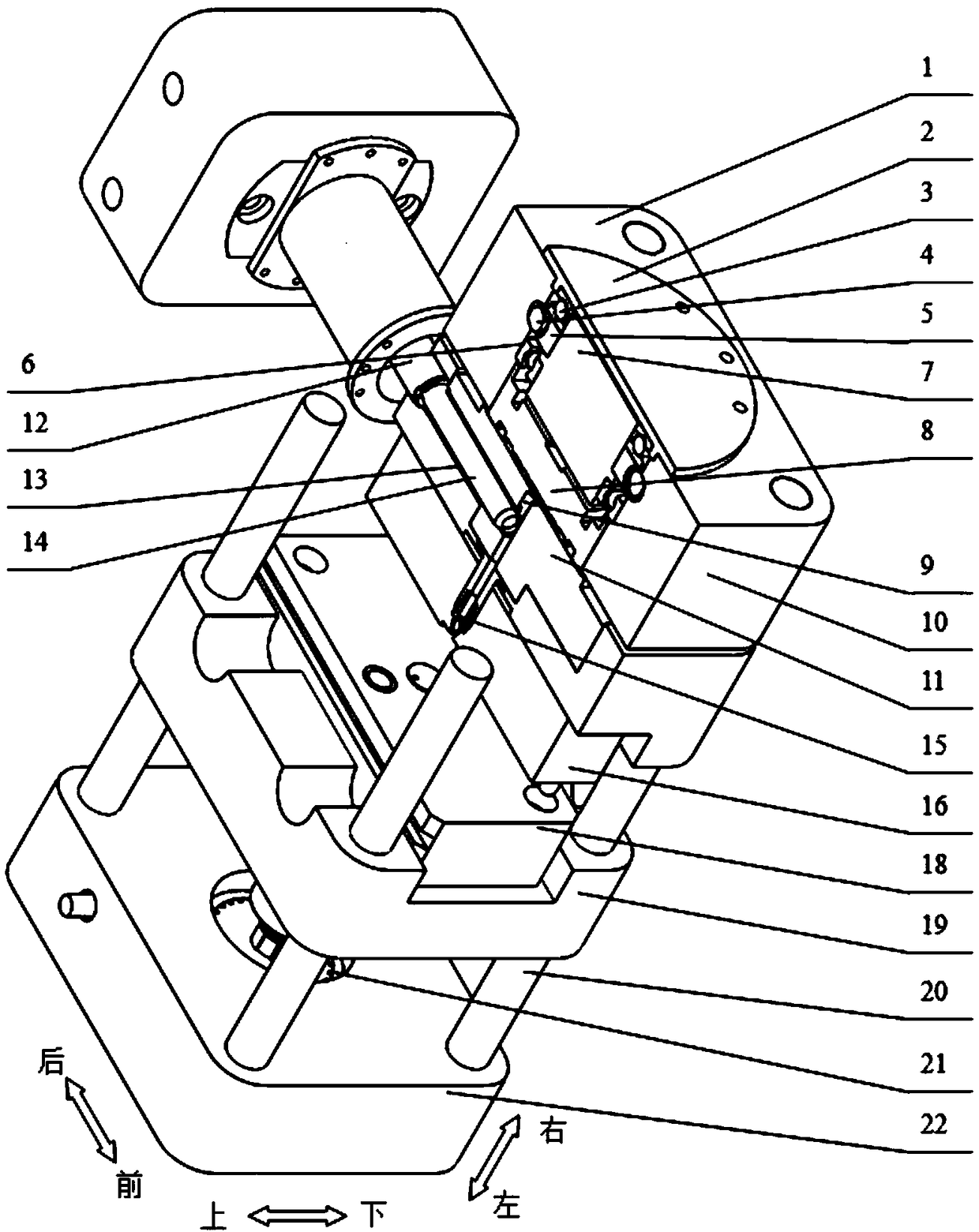

[0030] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will become more obvious.

[0031] Such as figure 1 , figure 2 , image 3 As shown, a micro-injection molding machine whose injection is at right angles to the plasticizing axis includes a grinding disc plasticizing device, a mould, a mold clamping drive device and a clamping plate that are sequentially worn on the pull rod; it also includes an injection drive device; the injection The driving device is installed on the grinding disc plasticizing device, and the axis of the injection driving device and the axial direction of the grinding disc plasticizing device are perpendicular to each other.

[0032] The injection drive device 1 includes a drive mechanism and a spline ball screw 101, the drive mechanism drives the spline ball screw 101 to realize the reciprocating motion of the spline ball screw 101 along its own ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com