Dynamic adjustment method for process parameters in selective laser sintering sub regions

A technology of laser selective sintering and process parameters, which is applied in processing data acquisition/processing, processing and manufacturing, additive processing, etc., can solve the problems of reducing or not considering the pertinence of parts control, reducing the amount of temperature field information, etc., to achieve quality Good, direct and effective temperature control, flexible and effective temperature field control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the practical application of the invention is not limited to the following embodiments.

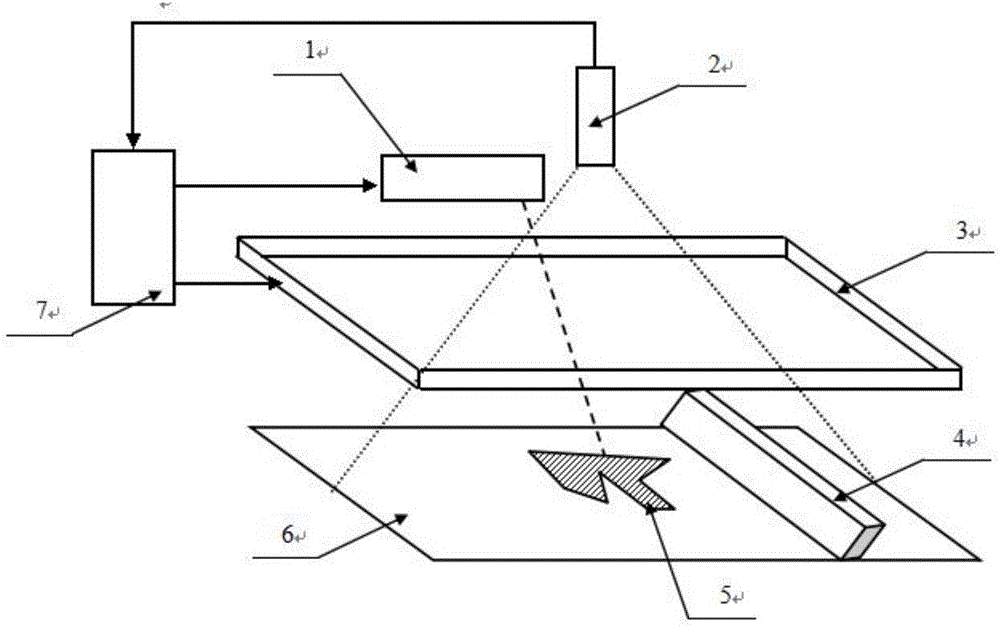

[0032] The composition of the working system of this embodiment is as follows: figure 1 As shown, in the processing process of one layer, a layer of powder is laid on the powder bed plane 6 by the powder spreading device 4 first, and after the powder spreading is completed, the infrared thermal imager 2 detects the temperature distribution of the powder bed plane 6, and then the temperature field The distribution information is sent to the computer 7, and the computer 7 analyzes and processes the incoming temperature field data, and then controls the preheating device 3 or the laser 1 to perform corresponding operations to complete the sintering of a slice profile 5, and so on, and finally completes Sintering of entire three-dimensional objects.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com