Molding device and molding method

A molding equipment and molding method technology, applied in the direction of processing and manufacturing, additive processing of mixtures of solid materials and liquid materials, additive processing, etc., can solve problems such as increasing costs, achieve convenient trial production, reduce production costs, and optimize molding effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

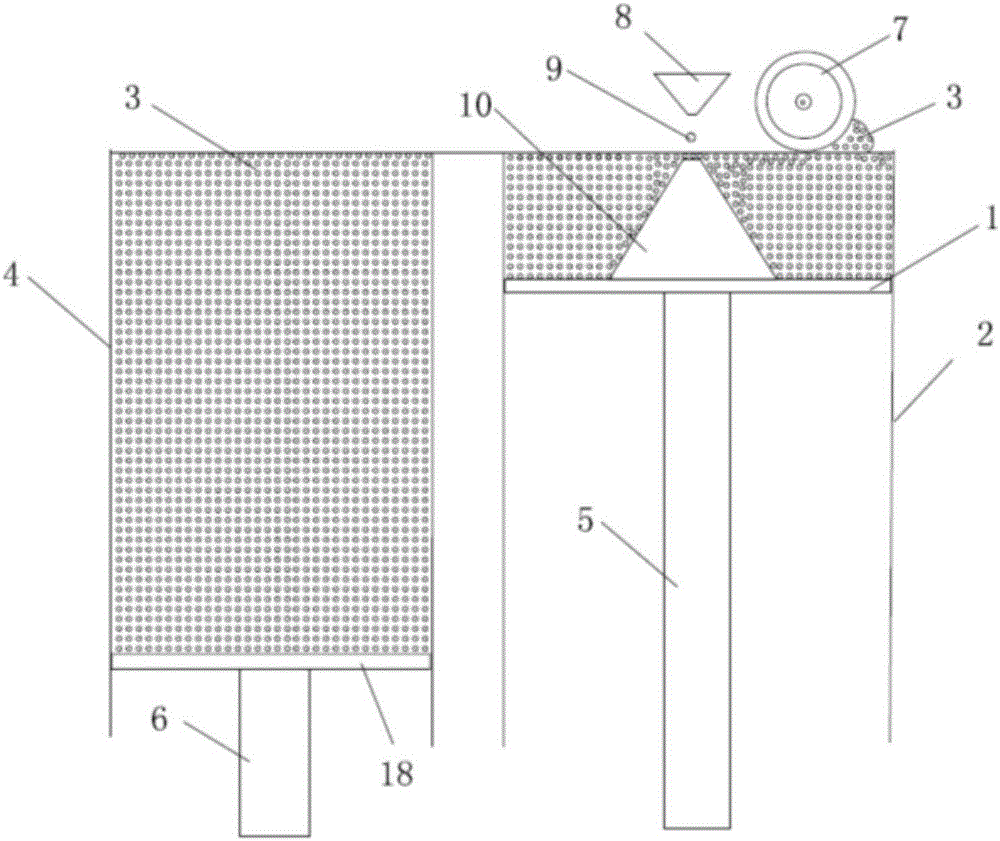

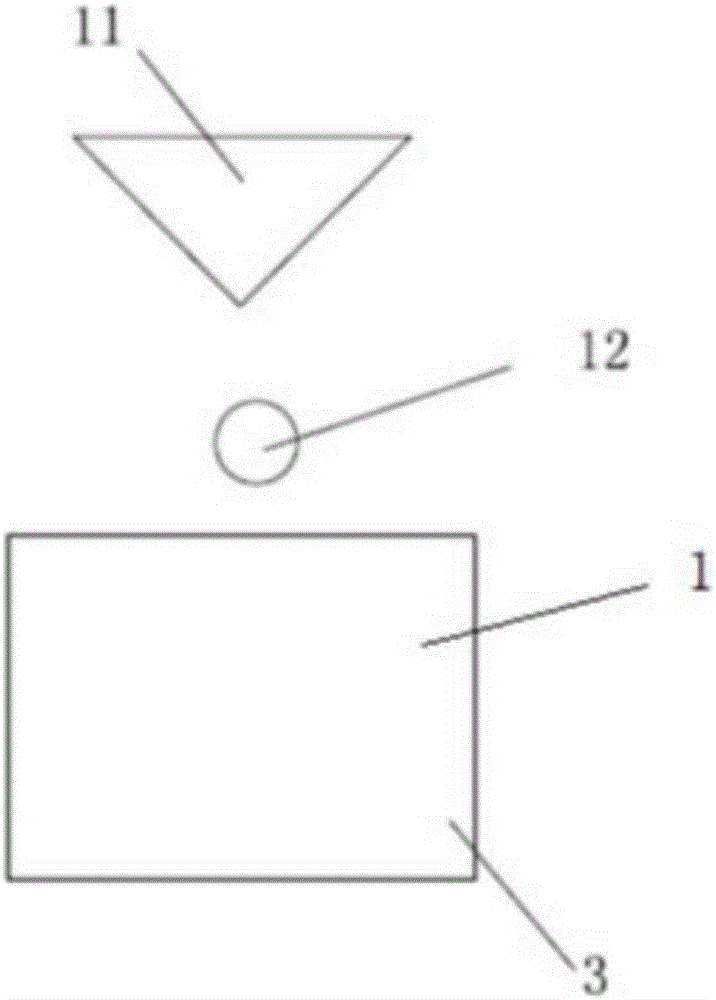

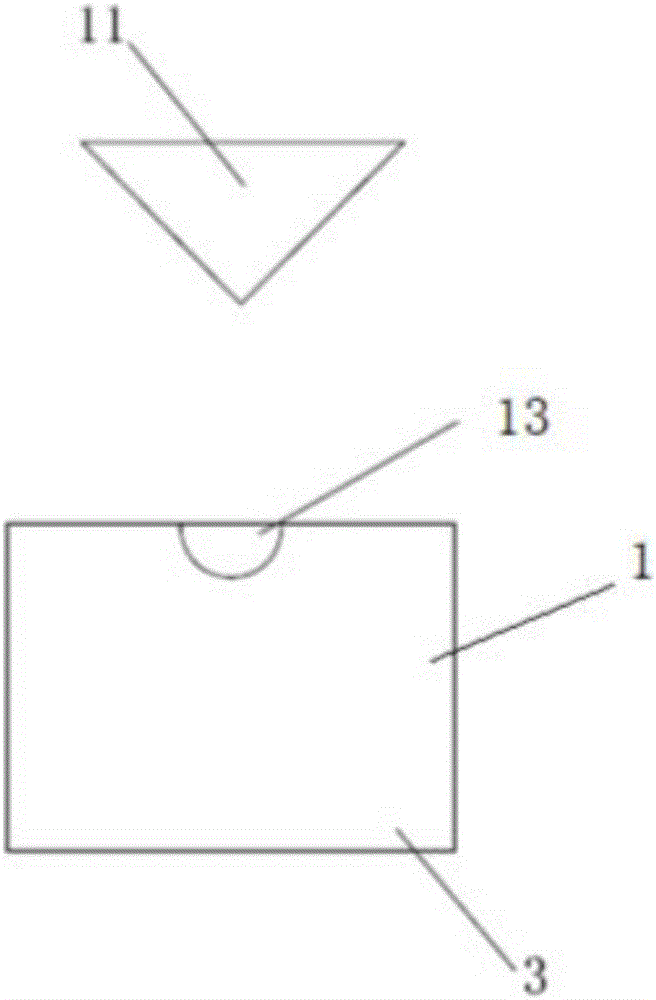

[0046] The invention provides a molding equipment, comprising a molding powder dispersing device, a spraying device, a molding cavity, a control device and a driving device; the molding powder dispersing device includes a molding powder bin, a molding powder conveying device and a molding powder pushing and scraping device; The molding powder pushing and scraping device includes a roller connected to the driving device; the injection device is arranged on the upper part of the opening of the molding cavity; the molding powder bin and the molding cavity are respectively provided with a lifting device; the injection device at least includes The first nozzle and the second nozzle.

[0047] It can be understood that the shaped powder 3 may contain an initiator or a catalyst, which can reduce the amount of liquid or speed up the curing speed. The same kind of solidifying liquid can be used in several kinds, each of which contains different color elements, and is sprayed out by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com