Preparation method of composite functional material for sound absorption and noise reduction with gradual impedance gradient

A composite function and sound-absorbing technology, which is applied in the field of textile materials, can solve the problems of not meeting the requirements of lightweight interior materials for traffic functions, occupying space in the car, and increasing the thickness of materials, so as to achieve good novelty, improve absorption efficiency, The effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention discloses a process preparation method of a composite functional material for sound absorption and noise reduction with gradually changing impedance, which specifically includes the following:

[0026] The processing technology of the pollution-repelling and sound-absorbing decorative layer is as follows:

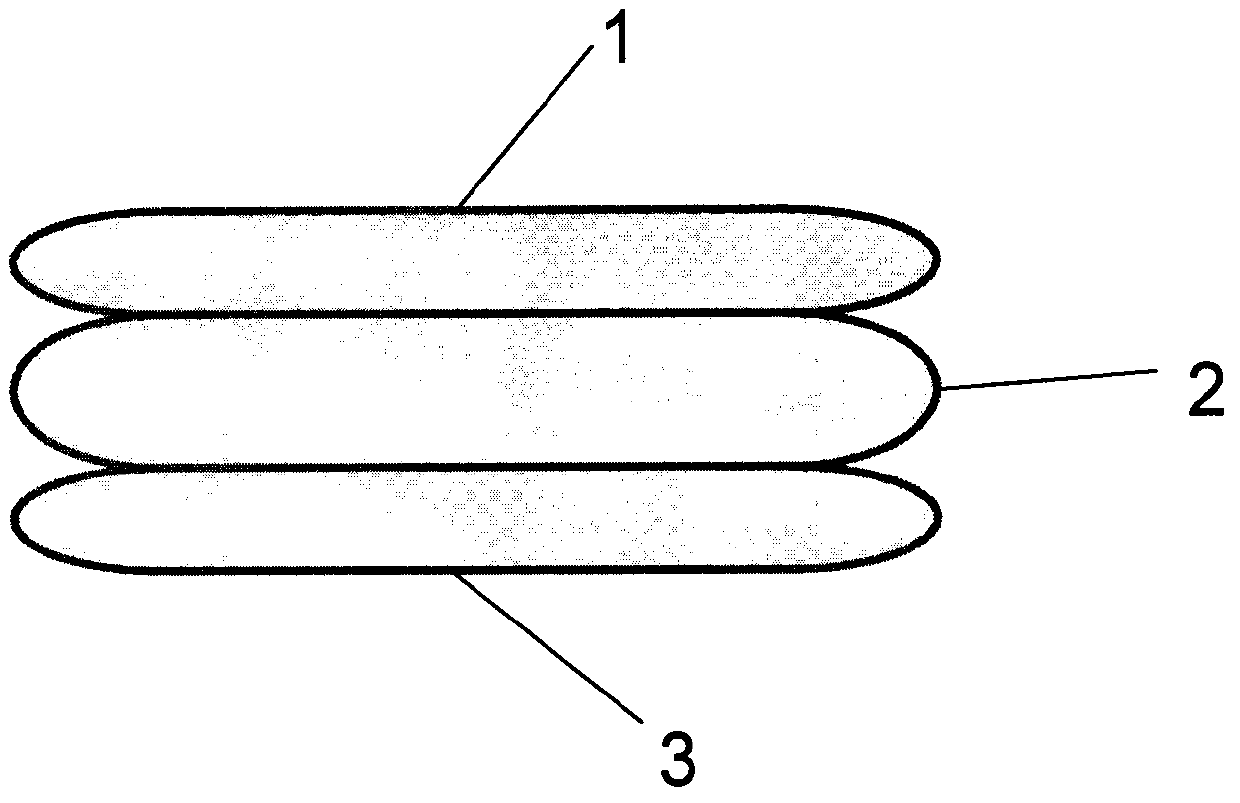

[0027] 1) Process polypropylene fibers with triangular cross-sections into needle-punched nonwovens through carding, laying, pre-needling, main needling, suede needling, etc., to form a pollution-repelling and sound-absorbing decorative layer for sound-absorbing products1 ;

[0028] 2) Use the padding method for flame retardant finishing, two dipping and two rolling at room temperature, the liquid rolling rate is 75%, then pre-baking at 110°C for 10 minutes, baking at 175°C for 2.5 minutes, steaming for 10 minutes, washing in cold water for 10 minutes, and drying Drying and finishing working solution: ammonium polyphosphate 120g / L, JHF-9 high-efficienc...

Embodiment 2

[0039] The invention discloses a process preparation method of a composite functional material for sound absorption and noise reduction with gradually changing impedance, which specifically includes the following:

[0040] The processing technology of the pollution-repelling and sound-absorbing decorative layer is as follows:

[0041] 1) Process polypropylene fibers with triangular cross-sections into needle-punched nonwovens through carding, laying, pre-needling, main needling, suede needling, etc., to form a pollution-repelling and sound-absorbing decorative layer for sound-absorbing products1 ;

[0042] 2) Use the padding method for flame retardant finishing, two dipping and two rolling at room temperature, the liquid rolling rate is 70%, then pre-baking at 130°C for 6 minutes, baking at 185°C for 1 minute, steaming for 12 minutes, washing in cold water for 10 minutes, and drying , Finishing working solution: ammonium polyphosphate 100g / L, JHF-9 high-efficiency flame retar...

Embodiment 3

[0053] The invention discloses a process preparation method of a composite functional material for sound absorption and noise reduction with gradually changing impedance, which specifically includes the following:

[0054] The processing technology of the pollution-repelling and sound-absorbing decorative layer is as follows:

[0055] 1) Process polypropylene fibers with triangular cross-sections into needle-punched nonwovens through carding, laying, pre-needling, main needling, suede needling, etc., to form a pollution-repelling and sound-absorbing decorative layer for sound-absorbing products1 ;

[0056] 2) Use the padding method for flame retardant finishing, two dipping and two rolling at room temperature, the liquid rolling rate is 65%, then pre-baking at 100°C for 10 minutes, baking at 195°C for 0.5 minutes, steaming for 8 minutes, washing in cold water for 10 minutes, and drying Drying and finishing working solution: ammonium polyphosphate 120g / L, JHF-9 high-efficiency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com