Buffer type storage device for thin-film laminating machine

A composite machine and film technology, which is applied to lamination devices, layered products, lamination, etc., can solve the problems of poor connection effect, non-compact, inaccurate bonding, etc., and achieve firm and accurate bonding More, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

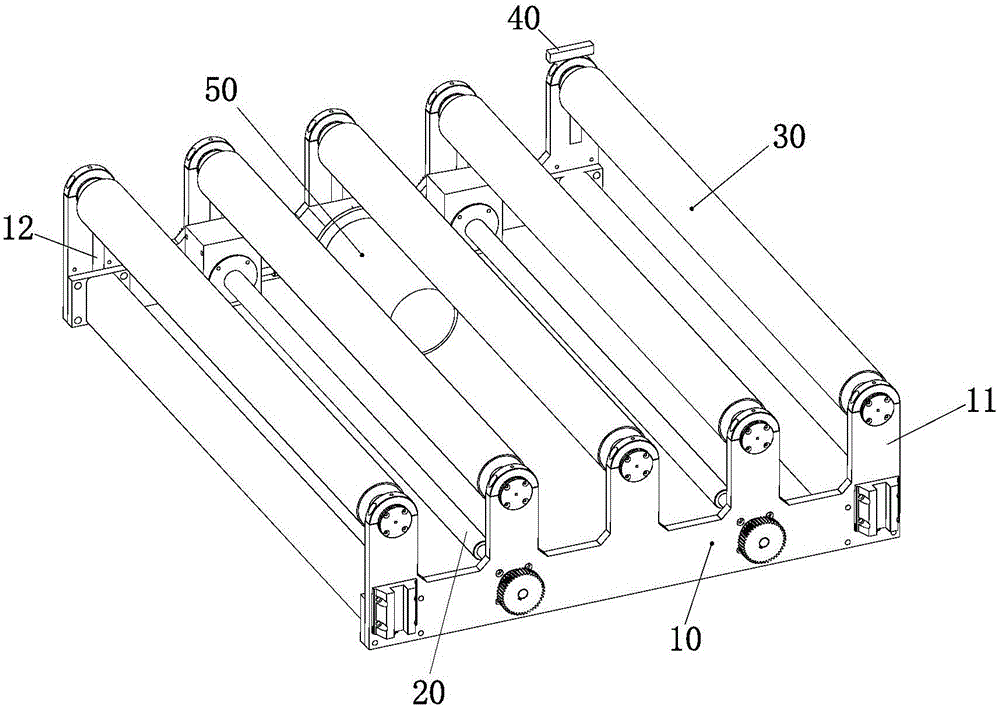

[0016] Such as figure 1 As shown, the buffer storage device of a film compound machine in this embodiment includes a storage rack 10 and a number of support plates 11 arranged on the storage rack 10, and a number of fixed guide rollers are installed at the bottom of the storage rack 10 20. Each support plate 11 is provided with a movable guide roller 30, and the support plate 11 is also provided with a guide rail 12, and the movable guide roller 30 can move up and down on the guide rail 12. The buffer storage device should be set after the material receiving device and before the winding device. After the film passes through the feeding device, it is wound in an S shape on the fixed guide roller 20 and the movable guide roller 30, and then connected to the winding device. The movable guide roller 30 can move relative to the fixed guide roller 20, thereby increasing or decreasing the distance between the two, and lengthening or reducing the length of the wound film. When the ...

Embodiment 2

[0018] Such as figure 1 As shown, the buffer storage device of the film composite machine in this embodiment further includes a storage motor 50 , and the storage motor 50 drives the movable guide roller 30 to move up and down on the track 12 . The support plate 11 is also provided with a travel switch 40, the travel switch 40 is connected with the storage motor 50, and the storage motor 50 rotates forward, so that the movable guide roller 30 moves up, and the gap between the movable guide roller 30 and the fixed guide roller 20 is increased. distance. When movable guide roller 30 moves up to a certain degree, runs into travel switch 40, and travel switch 40 then controls storage material motor 50 to stop working, avoids movable guide roller 30 to move out support plate 11. The stocker motor 50 reverses, and the movable guide roller 30 descends, reducing the distance with the fixed guide roller 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com