Delaying bin

A silo and storage cavity technology, which can be used in the destacking of objects, stacking of objects, conveyor objects, etc., which can solve the problems of inflexible use and large space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0029] The orientations involved in this manual are all based on the orientation of the time-delay silo of the present invention when it is working normally, and are not limited to its orientation during storage and transportation, and only represent relative positional relationships, not absolute positional relationships.

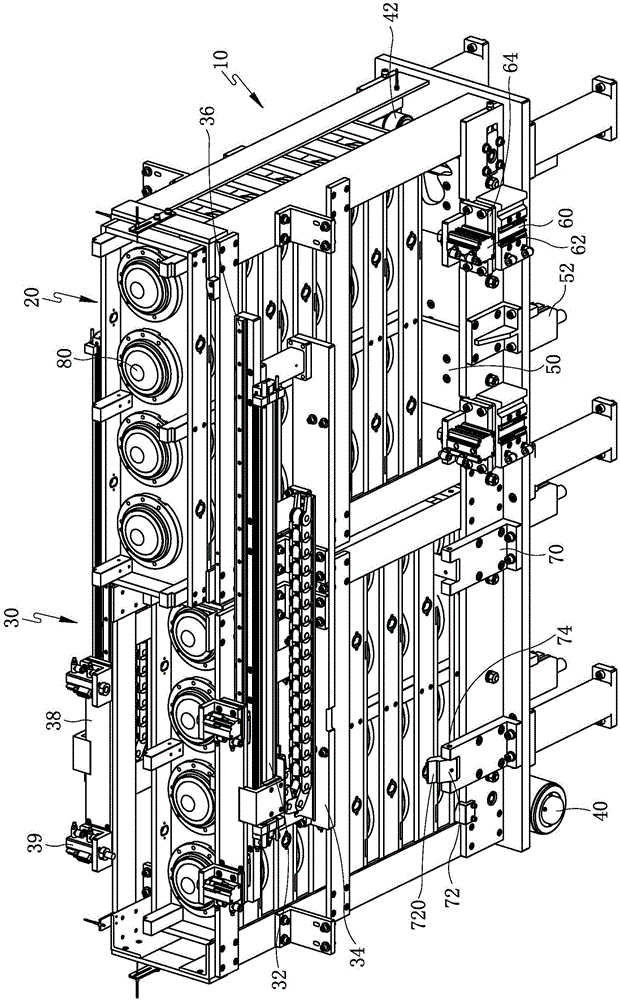

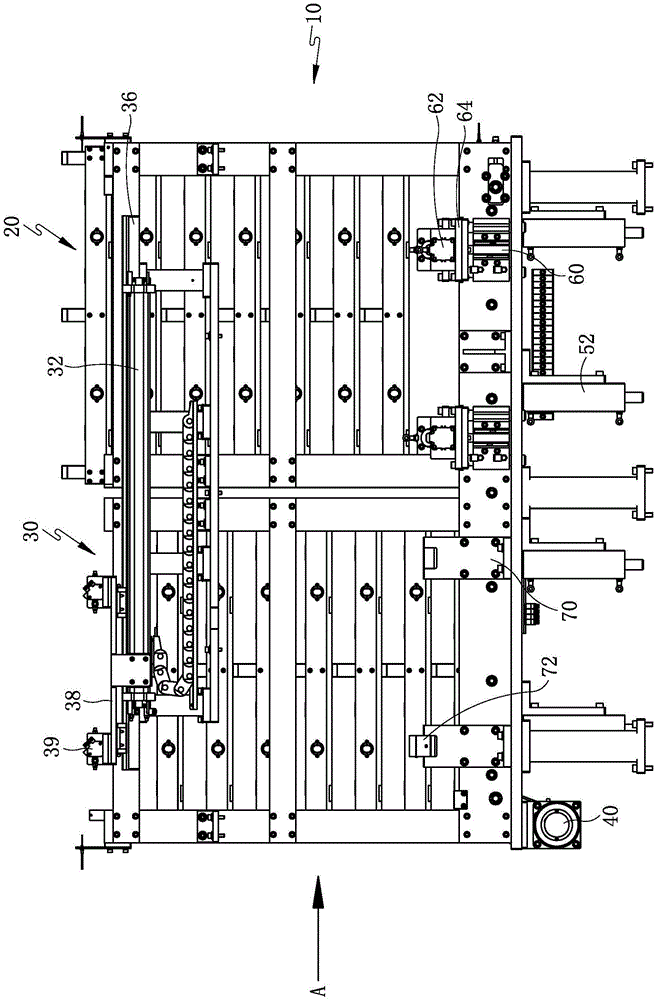

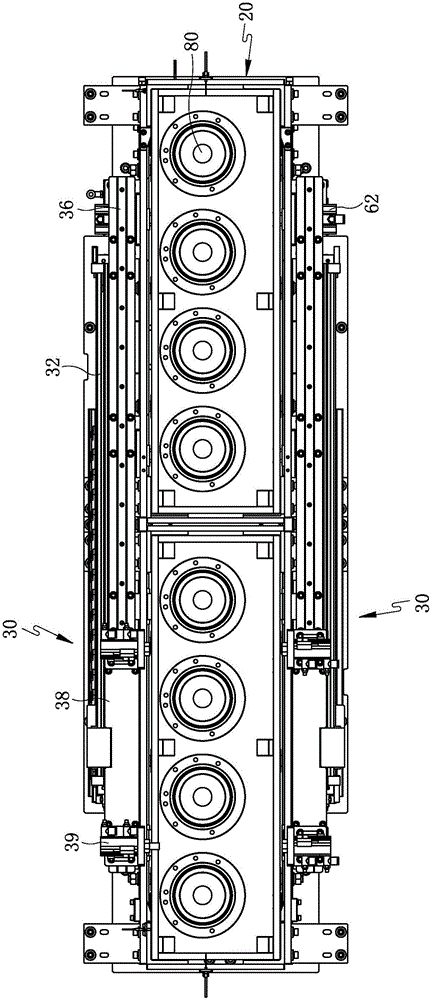

[0030] Such as figure 1 , figure 2 and Figure 5 Commonly shown, a kind of time-delay silo comprises a support frame 10, and the support frame 10 comprises a rectangular installation base plate 12 placed horizontally, a plurality of legs 14 are fixed on the lower side of the installation base plate 12, and the upper side of the installation base plate 12 is vertical A frame is fixed to the direction, and the frame and the installation base plate 12 together form a product storage cavity, the product storage cavity is open at the upper end, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com