Vertical pit furnace bracket type tray

A support type and pit type furnace technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of many casting defects, complex structure, low life, etc., and achieve low heat absorption rate, high benefit, and easy casting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

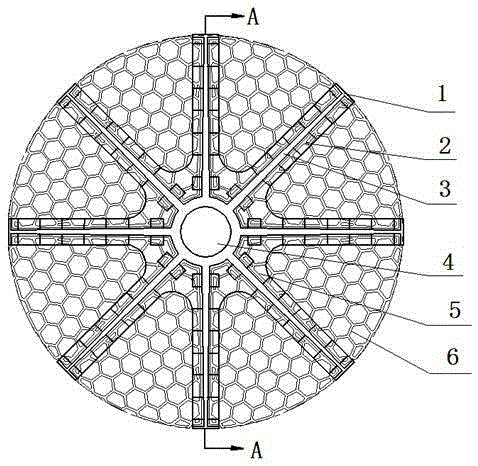

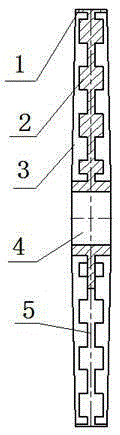

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings. like figure 1 , figure 2 Shown, a kind of well-type furnace bracket type tray of the present invention, it comprises middle sleeve 4 and eight brackets 5, and described bracket 5 is fixed on the outer wall of middle sleeve 4 by the circumference equally divided, and described middle sleeve The cylinder 4 and the support 5 are cast into one body by an integral casting process, and a honeycomb fan-shaped tray 6 is installed between two adjacent supports 5; the two sides of each support 5 are respectively provided with a pallet 2, and the A honeycomb fan-shaped material tray 6 is installed on the pallet 2 between two adjacent supports 4; the end of each support 5 is provided with an anti-off plate 1; Reinforcing ribs 3 are provided on the sides respectively.

[0020] The embodiment is only for the convenience of understanding the technical solution of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com