Special soft and wear-proof shoe material and preparation method thereof

A soft and wear-resistant, special-purpose material technology, applied in applications, soles, footwear, etc., can solve the problems of softness and wear resistance, and achieve the effect of improving wear resistance and lightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

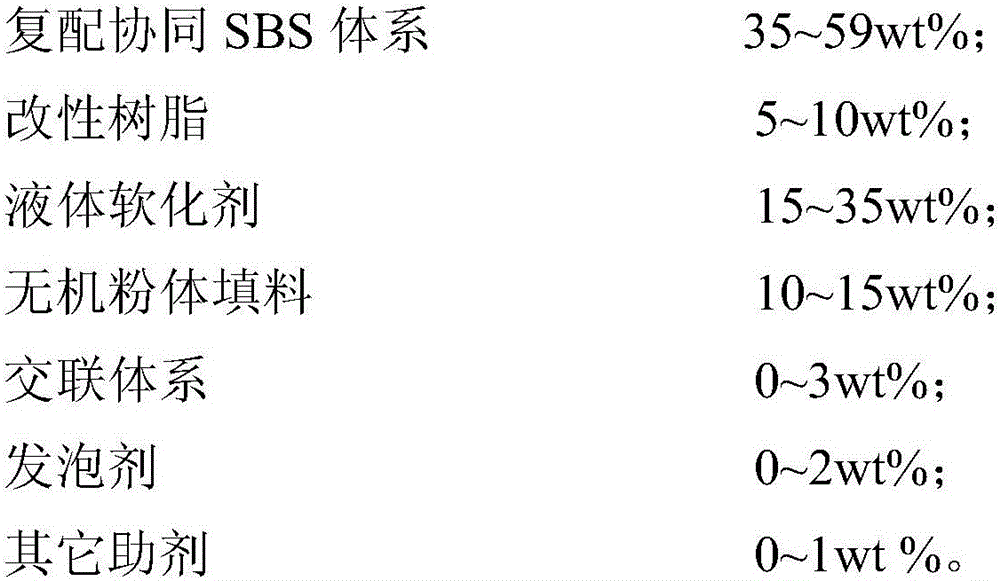

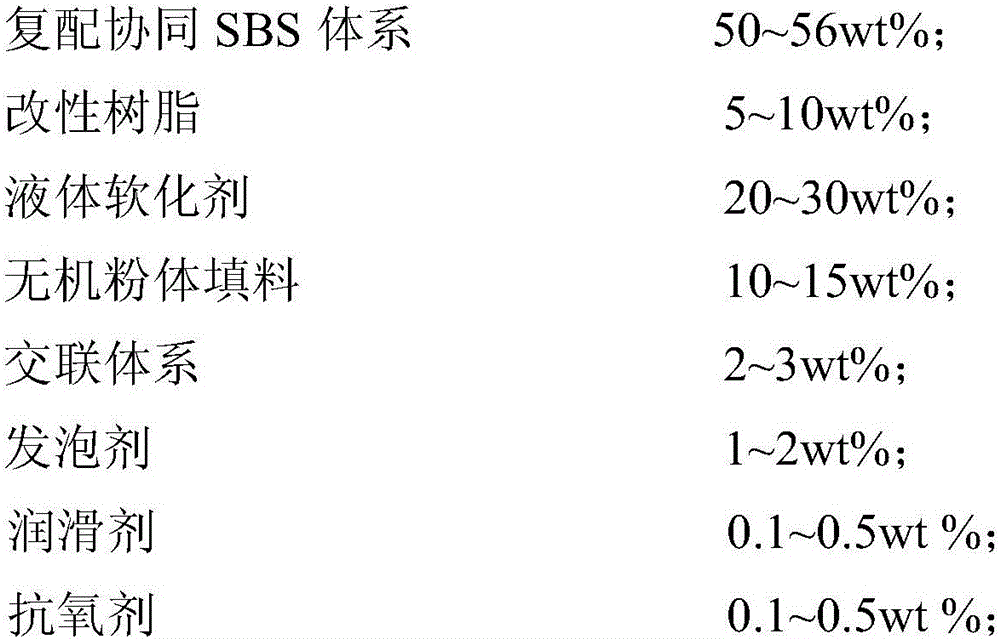

Method used

Image

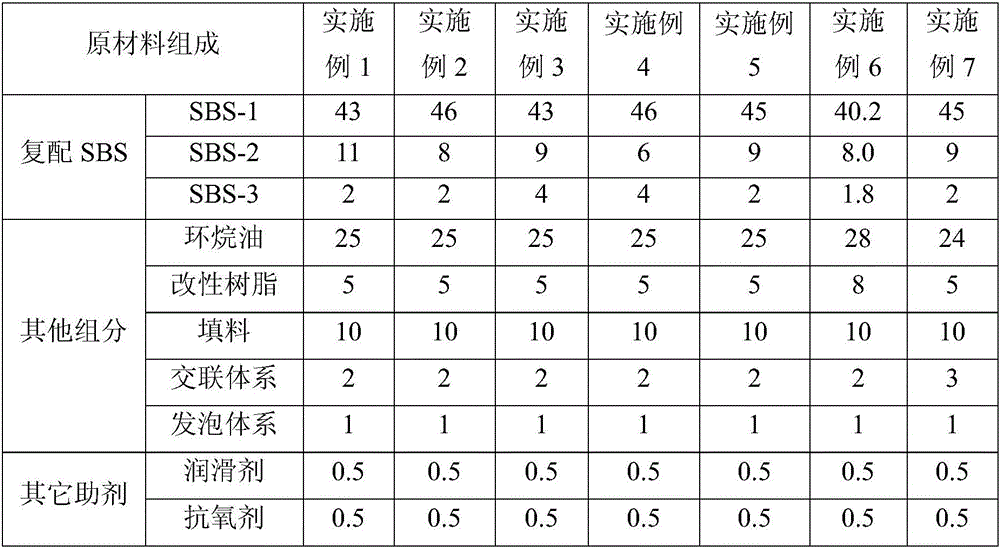

Examples

Embodiment 1

[0044] (1) Oil-extended SBS

[0045]Add various SBS, liquid softener and various additives in proportion to the slow mixer, complete the oil filling of SBS under low-speed stirring, and the oil filling temperature can be set at about 60°C;

[0046] Among them, SBS-1 is Kraton 1186 (32% styrene content, number average molecular weight about 200,000, star structure); SBS-2 is Kraton KX408 (44% styrene content, linear structure); SBS-3 is Kraton KX222 (18% styrene content, star structure);

[0047] The liquid softener is naphthenic oil, the brand is Kelian 4006;

[0048] The lubricant is silicone and the antioxidant is 1010;

[0049] (2) Mixing of components

[0050] In the high mixer, add modified resin polystyrene (grade: GPPS-500N) and inorganic powder filler calcium carbonate (2000 mesh) in proportion, crosslinking system (di-tert-butyl peroxide and triallyl iso The mass ratio of cyanurate is 1:1), AC blowing agent, make material mix evenly under high-speed stirring, dry ...

Embodiment 2

[0057] The implementation process is the same as in Example 1, except that the ratio of SBS-1 and SBS-2 is adjusted. Other materials and proportioning are shown in Table 1, and the obtained material results are shown in Table 2.

Embodiment 3

[0059] The implementation process is the same as in Example 1, except that the ratio of SBS-2 and SBS-3 is adjusted. Other materials and proportioning are shown in Table 1, and the obtained material results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com